Vapor phase inhibitor and preparation method thereof

A gas-phase corrosion inhibitor and synergist technology, which is applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve problems such as pipeline corrosion, and achieve the effect of slowing down corrosion, environmental protection and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The gas-phase corrosion inhibitor of this embodiment is composed of the following components in mass percentage: 20% of 2-mercaptobenzimidazole, 40% of cyclohexylamine carbonate, 2% of hexamethylenetetramine, 3% of ammonium benzoate, carbon Amide 5%, acetone 30%.

[0039] The preparation method of the vapor phase corrosion inhibitor of the present embodiment may further comprise the steps:

[0040] According to the above formula, measure acetone in a reaction kettle with a temperature-controlled frequency conversion mixer, adjust the temperature to 50°C, and add 2-mercaptobenzimidazole and cyclohexylamine carbonate at a speed of 300r / min, and then slowly add hexamethylene Tetramine, ammonium benzoate and carbonamide, and then stirred for 30 minutes until fully dissolved, and the mixed liquid became uniform and clear.

Embodiment 2

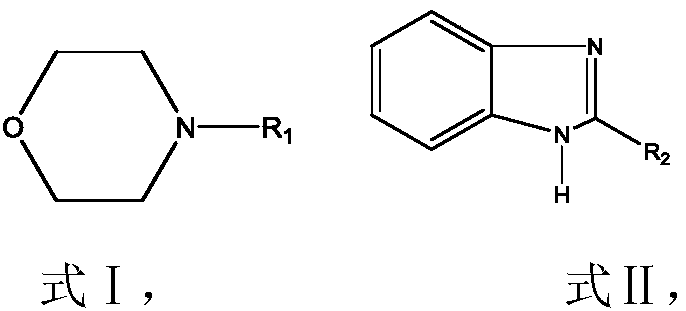

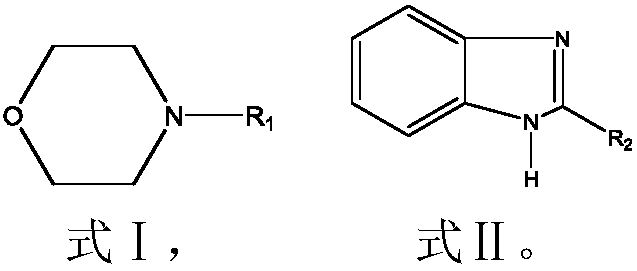

[0042] The vapor phase corrosion inhibitor of this example is composed of the following components in mass percentage: 20% of N,N'-dicyclohexyl-4-morpholine amidine, 40% of cyclohexylamine carbonate, and 1.0% of hexamethylenetetramine , Ammonium Benzoate 1.5%, Carboxamide 2.5%, Isopropanolamine 35%.

[0043] The preparation method of the vapor phase corrosion inhibitor of the present embodiment may further comprise the steps:

[0044] According to the above formula, measure isopropanolamine in a reaction kettle with a temperature-controlled frequency conversion mixer, adjust the temperature to 50°C, and add N,N'-dicyclohexyl-4-morpholine amidine, Cyclohexylamine carbonate, then slowly add hexamethylenetetramine, ammonium benzoate and carboxamide, and then stir for 30 minutes until fully dissolved, and the mixed liquid becomes uniform and clear.

Embodiment 3

[0046] The vapor phase corrosion inhibitor of this embodiment is composed of the following components in mass percentage: 35% of N,N'-dicyclohexyl-4-morpholine amidine, 35% of dicyclohexylamine benzoate, and hexamethylenetetramine 2.0%, Ammonium Benzoate 3%, Carboxamide 5%, Acetone 20%.

[0047] The preparation method of the vapor phase corrosion inhibitor of the present embodiment may further comprise the steps:

[0048] According to the above formula, measure acetone in a reaction kettle with a temperature-controlled frequency conversion mixer, adjust the temperature to 50°C, and add N,N'-dicyclohexyl-4-morpholine amidine, benzoic acid di Cyclohexylamine, then slowly add hexamethylenetetramine, ammonium benzoate and carbamide, and then stir for 30 minutes until fully dissolved, and the mixed liquid becomes uniform and clear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com