Organic light-emitting device

An electroluminescent device and luminescent technology, applied in the field of display, can solve the problems of low current efficiency, achieve the effects of improving current efficiency, increasing recombination area, and reducing driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

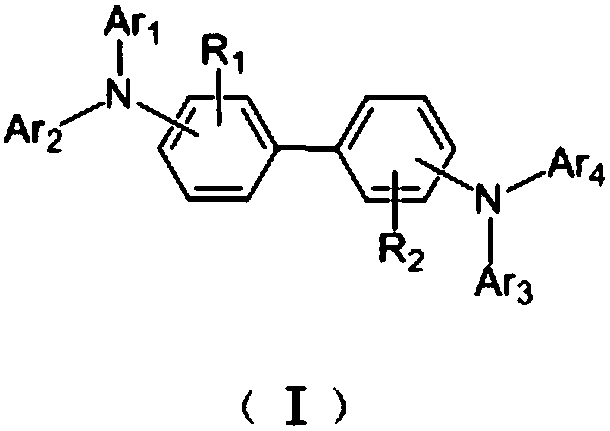

Method used

Image

Examples

Embodiment 1

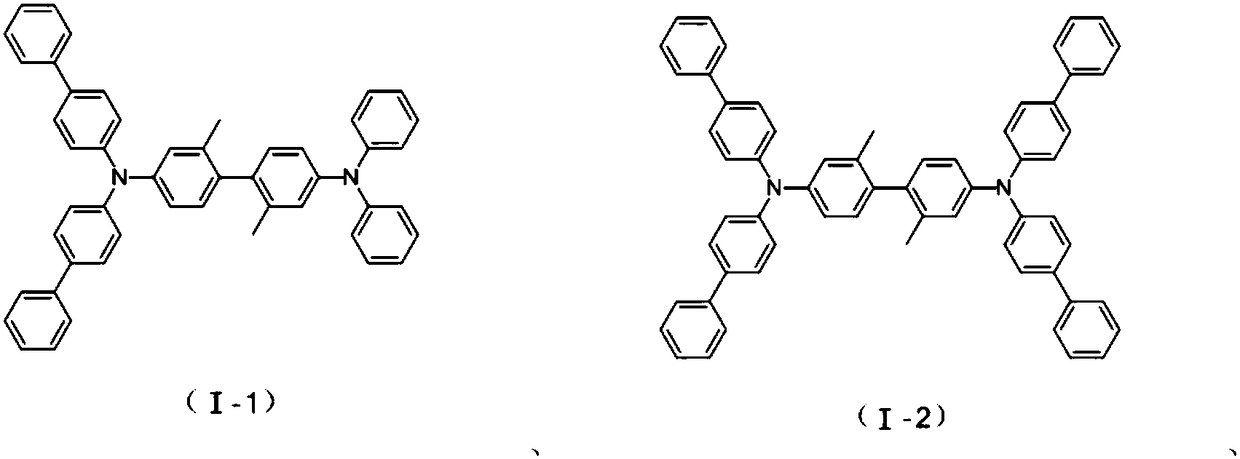

[0058] The structure of the organic electroluminescent device provided by this implementation is: ITO (20nm) / formula (I-1): F4TCNQ (4wt%, 20nm) / formula (II-1) (76nm) / AND: perylene (3wt%, 30nm) / Bphen(25nm) / Ag(16nm) / Alq3(65nm).

[0059] Wherein, ITO: indium tin oxide, is the first electrode;

[0060] AND: 9,10-bis(2-naphthyl)anthracene, a dopant material for the light-emitting layer;

[0061] Perylene: perylene, which is the main material of the light-emitting layer;

[0062] Bphen: 4,7-diphenyl-1,10-phenanthroline, an electron transport layer material;

[0063] Ag: silver, is the second electrode;

[0064] Alq3: Tris(8-hydroxyquinoline)aluminum, which is an optical coupling layer.

[0065] The first hole transport material is formula (I-1), the P-type dopant material is F4TCNQ, the ratio of the mass of the P-type dopant material to the mass of the first hole transport material is 4:100; the hole injection layer 30 The thickness of the hole transport layer 40 is 20 nm; the ...

Embodiment 2

[0076] This embodiment provides an organic electroluminescence device, the specific structure is the same as that of Embodiment 1, the difference is that the first hole transport material is formula (I-1), the P-type dopant material is F4TCNQ, and the hole injection layer 30 The thickness of the hole transport layer 40 is 10 nm, the doping concentration of the P-type dopant material is 8%; the second hole transport material is formula (II-2), and the thickness of the hole transport layer 40 is 86 nm.

Embodiment 3

[0078] This embodiment provides an organic electroluminescent device, the specific structure is the same as that of Embodiment 1, the difference is that the first hole transport material is formula (I-2), the P-type dopant material is F4TCNQ, and the hole injection layer 30 The thickness of the hole transport layer 40 is 10 nm, the doping concentration of the P-type dopant material is 4%; the second hole transport material is formula (II-3), and the thickness of the hole transport layer 40 is 86 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com