Flexible and high-telescopic nanofiber core spun yarn stress sensor with pleated structure and preparation method of stress sensor

A technology of stress sensors and nanofibers, applied in the field of flexible sensors, can solve the problems of lack of stretchability of pressure sensor arrays and large gaps between human skin, etc., and achieve the effects of wide strain range, fast response speed and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of the flexible and highly stretchable nanofiber core-spun yarn stress sensor with a wrinkled structure is as follows:

[0026] (1) Dissolve polyacrylonitrile (PAN) in N,N dimethylformamide (DMF) solvent, and stir at 80°C for 6 h to obtain a PAN solution with a mass fraction of 8%;

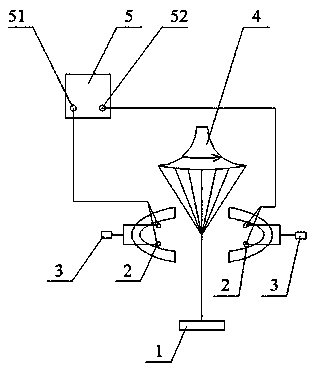

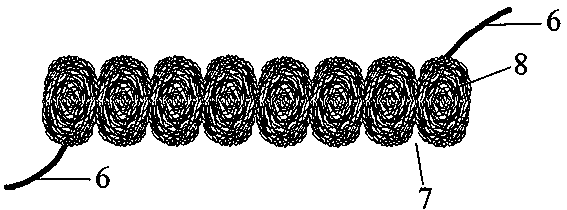

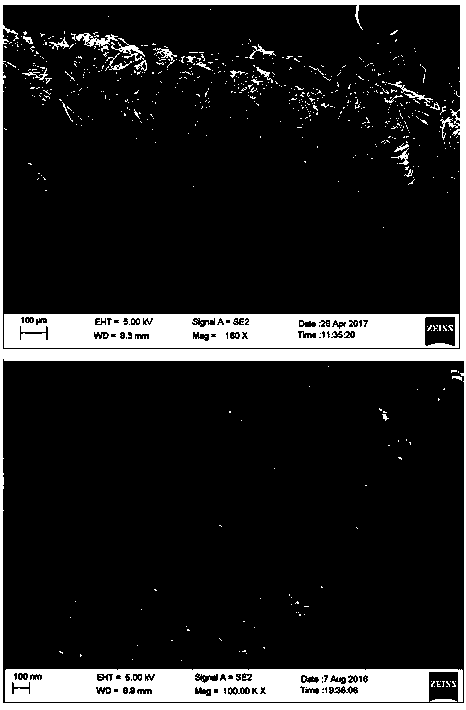

[0027] (2) Build the electrospinning device according to Figure 1, add the PAN solution in step (1) to the syringe pump to prepare continuous nanofiber yarn, the elongation of the elastic filament is equal to 100%, and the electrospinning voltage is 17.5 kV, the total flow rate of the spinning solution is 0.6 mL / h, the diameter of the metal horn is 10 cm, the vertical distance between the metal horn and the winding device is 50 cm, the vertical distance between the nozzle and the metal horn is 4 cm, the distance between the nozzle and the metal The horizontal distance of the horn is 3 cm, the number of nozzles is 4, the inner diameter of the nozzle is 0.4 mm, the solu...

Embodiment 2

[0033] The preparation method of the flexible and highly stretchable nanofiber core-spun yarn stress sensor with a wrinkled structure is as follows:

[0034] (1) Polyvinylidene fluoride (PVDF) was dissolved in a mixed solvent of N,N dimethylformamide (DMF) and tetrahydrofuran (mass ratio 1:1), stirred at 80°C for 6 h to obtain a mass fraction of 16.5% PVDF solution;

[0035] (2) Build the electrospinning device according to Figure 1, add the spinning solution in step (1) to the syringe pump to prepare continuous nanofiber yarn, the elongation of the elastic filament is equal to 150%, and the electrospinning The voltage was 17.5 kV, the total flow rate of the spinning solution was 0.6 mL / h, the diameter of the metal horn was 10 cm, the vertical distance between the metal horn and the winding device was 50 cm, the vertical distance between the nozzle and the metal horn was 4 cm, and the distance between the nozzle and the winding device was 50 cm. The horizontal distance of the...

Embodiment 3

[0040] The preparation method of the flexible and highly stretchable nanofiber core-spun yarn stress sensor with a wrinkled structure is as follows:

[0041] (1) Polyurethane (PU) was dissolved in a mixed solvent of N,N dimethylformamide (DMF) and tetrahydrofuran (mass ratio 1:1), and stirred at room temperature for 8 h to obtain a PU solution with a mass fraction of 12%. ;

[0042] (2) Build the electrospinning device according to Figure 1, add the spinning solution in step (1) to the syringe pump to prepare continuous nanofiber yarn, the elongation of the elastic filament is equal to 200%, and the electrospinning The voltage is 20 kV, the total flow rate of the spinning solution is 0.6 mL / h, the diameter of the metal horn is 10 cm, the vertical distance between the metal horn and the winding device is 50 cm, the vertical distance between the nozzle and the metal horn is 4 cm, the nozzle and the The horizontal distance of the metal horn is 3 cm, the number of nozzles is 4, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com