Mineralized bone tissue engineering scaffold and preparation method thereof

A bone tissue engineering and skeleton technology, applied in the field of mineralized composite bone tissue engineering scaffolds and their preparation, can solve problems such as the adverse effect of growth factor activity, achieve excellent mineralization effect, fast mineralization, reduce treatment costs and potential effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of PCL / Zwitterionic Hydrogel Composite Scaffold

[0024] Dissolve 0.5 mmol of 3-(2-methacryloyloxyethyldimethylamino)propanesulfonate (SBMA) in 1.75 mL of phosphate-buffered saline (PBS), and add 50 μL of azo initiator VA-086 (10 mg / mL) and 25 μL cross-linking agent polyethylene glycol diacrylate to form a sulfonamide zwitterionic hydrogel prepolymer solution. Polycaprolactone (PCL) polymer was dissolved in 1,4-dioxane, and a porous polycaprolactone scaffold was prepared by freeze-drying; 50 μL of the sulfonamide prepared in this example was added dropwise on the surface of the porous PCL scaffold. Ionic hydrogel pre-polymerization solution, after the pre-polymerization solution completely infiltrates the inside of the stent, carry out ultraviolet crosslinking, after irradiating the front and back sides for 5 minutes, soak in a sterile phosphate buffer solution at 37°C for 12 hours, freeze-dry to remove water A PCL / zwitterionic hydrogel composite scaffo...

Embodiment 2

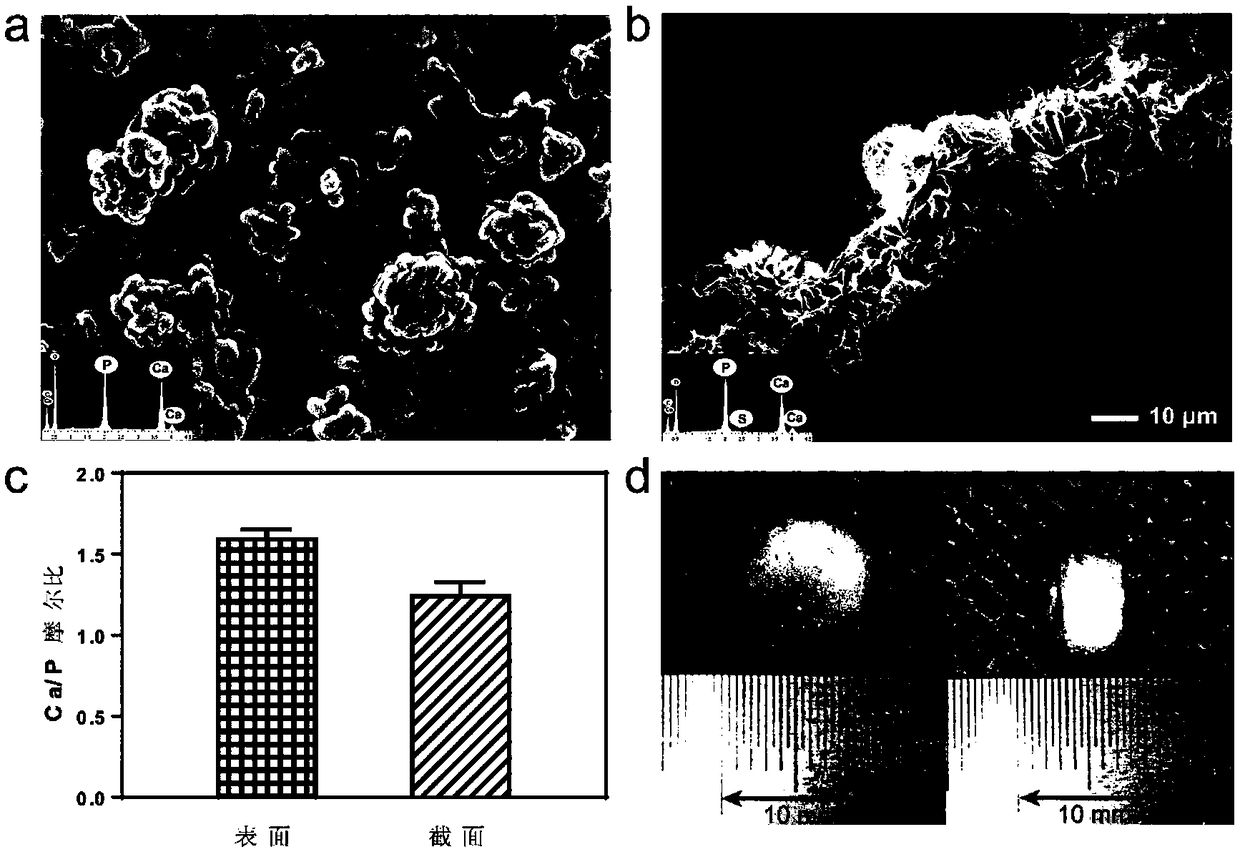

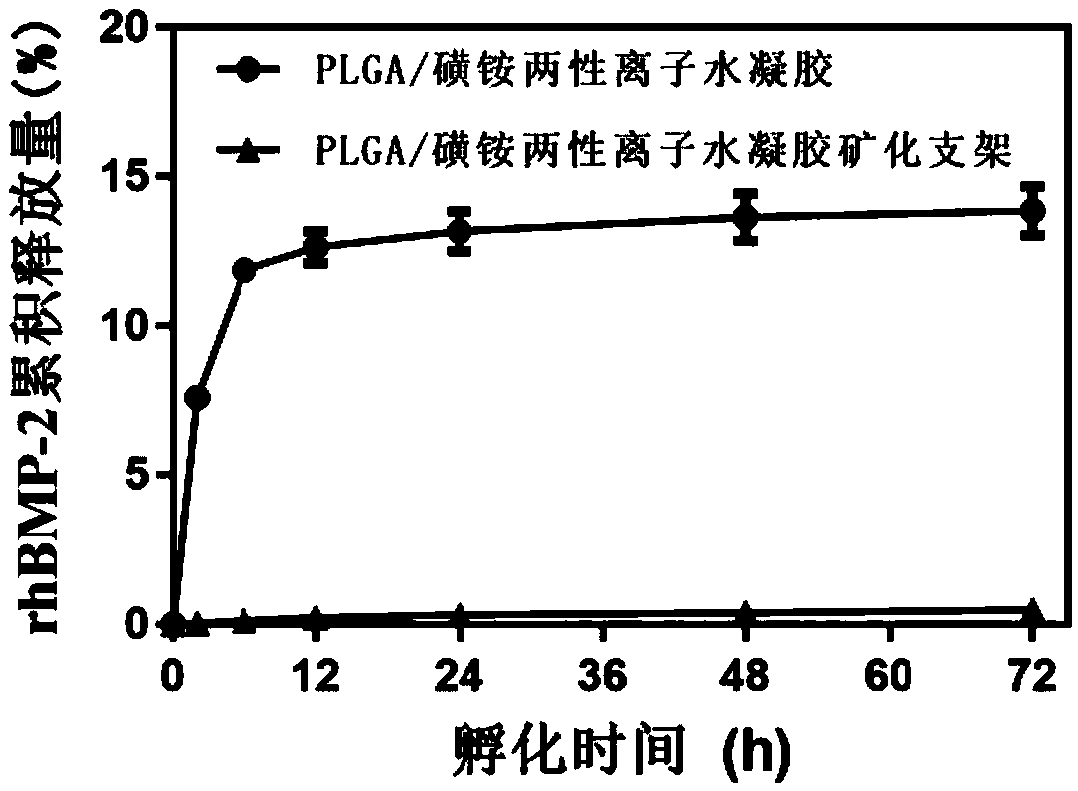

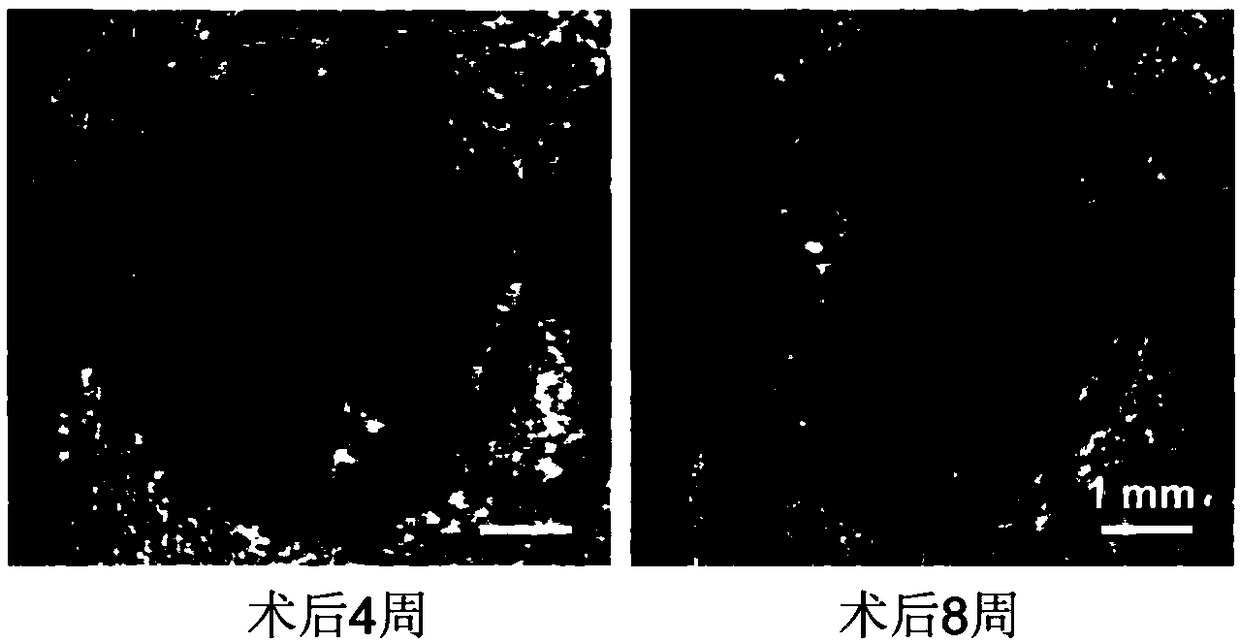

[0028] (1) Preparation of PLGA / Zwitterionic Hydrogel Composite Scaffold

[0029] Dissolve 1 mmol of 3-(2-methacryloyloxyethyldimethylamino)propanesulfonate (SBMA) in 3.5 mL of phosphate-buffered saline (PBS), and add 100 μL of azo initiator VA-086 ( 10 mg / mL) and 50 μL cross-linking agent polyethylene glycol diacrylate to form a sulfonium ammonium zwitterionic hydrogel prepolymer solution. Dissolve polylactic-co-glycolic acid (PLGA) in 1,4-dioxane, and prepare a porous polycaprolactone scaffold by freeze-drying; add 150 μL of the sulfonamide prepared in this example dropwise on the surface of the porous PLGA scaffold Zwitterionic hydrogel pre-polymerization solution, after the pre-polymerization solution completely infiltrates the inside of the scaffold, carry out ultraviolet crosslinking, after irradiating the front and back sides for 12 minutes, soak in 37 ℃ sterile phosphate buffer solution for 12 hours, freeze-dry to remove water After that, a PLGA / zwitterionic hydrogel com...

Embodiment 3

[0033] (1) Preparation of PLA / Zwitterionic Hydrogel Composite Scaffold

[0034] Dissolve 7 mmol of 3-[[2-(methacryloyloxy)ethyl]dimethylammonium]propionate (CBMA) in 9 mL of phosphate-buffered saline (PBS), and add 300 μL of azo initiator VA- 086 (10 mg / mL) and 70 μL cross-linking agent polyethylene glycol diacrylate to form a carboxyammonium zwitterionic hydrogel prepolymer solution. Polylactic acid (PLA) polymer was dissolved in 1,4-dioxane, and a porous polycaprolactone scaffold was prepared by freeze-drying; 200 μL of the carboxylamine zwitterion prepared in this example was added dropwise on the surface of the porous PLA scaffold Hydrogel pre-polymerization solution, after the liquid completely infiltrates the inside of the scaffold, carry out ultraviolet cross-linking, after irradiating the front and back sides for 15 minutes, soak in 37 ℃ sterile phosphate buffer solution for 12 hours, and freeze-dry to remove water to obtain amphoteric The PLA / zwitterionic hydrogel co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com