Magnetic oxygen carrier in hydrogen-rich syngas prepared by coal chemical looping gasification and preparation thereof

An oxygen carrier and chemical chain technology, which is applied in the field of preparation of oxygen carrier particles, can solve the problems of easy sintering and decreased cycle stability, and achieve the effects of efficient separation, simple preparation method, and stable catalytic water-vapor shift reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

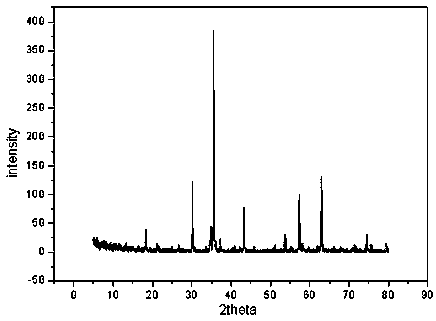

Image

Examples

Embodiment 1

[0020] Take 11.63gNi(NO 3 ) 2 ·6H 2 O and 32.32gFe(NO 3 ) 2 ·6H 2 Put O into a 500ml beaker, add 200ml of distilled water, stir until completely dissolved, and obtain A solution. Then take 9.12g of sodium borohydride and put it into a 500ml beaker, add 280ml of distilled water, stir until completely dissolved, and obtain B solution. Slowly and evenly add the above liquids A and B into the colloid mill, and stir for 3 minutes. Then add 1.06g of attapulgite, continue to stir for 1min, and transfer the above mixed solution to an autoclave with a 500ml polytetrafluoroethylene liner. Put the reactor into a drying oven at 150°C for hydrothermal crystallization for 12 hours. Then take out the reaction kettle, cool to room temperature naturally, centrifuge and wash to obtain NiFe 2 o 4 / Attapulgite composite oxygen carrier particles. After drying naturally in the air, put it in a muffle furnace, and raise the temperature from room temperature to 950°C at a rate of 3°C / min fo...

Embodiment 2

[0023] Take 11.63gNi(NO 3 ) 2 ·6H 2 O and 32.32gFe(NO 3 ) 2 ·6H 2 Put O into a 500ml beaker, add 200ml of distilled water, stir until completely dissolved, and obtain A solution. Then take 9.12g of sodium borohydride and put it into a 500ml beaker, add 280ml of distilled water, stir until completely dissolved, and obtain B solution. Slowly and evenly add the above liquids A and B into the colloid mill, and stir for 3 minutes. Then add 2.34g of attapulgite, continue to stir for 1min, and transfer the above-mentioned mixed solution to an autoclave with a 500ml polytetrafluoroethylene liner. Put the reactor into a drying oven at 150°C for hydrothermal crystallization for 12 hours. Then take out the reaction kettle, cool to room temperature naturally, centrifuge and wash to obtain NiFe 2 o 4 / Attapulgite composite oxygen carrier particles. After drying naturally in the air, put it in a muffle furnace, and raise the temperature from room temperature to 950°C at a rate of ...

Embodiment 3

[0025] Take 11.63gNi(NO 3 ) 2 ·6H2 O and 32.32gFe(NO 3 ) 2 ·6H 2 Put O into a 500ml beaker, add 200ml of distilled water, stir until completely dissolved, and obtain A solution. Then take 9.12g of sodium borohydride and put it into a 500ml beaker, add 280ml of distilled water, stir until completely dissolved, and obtain B solution. Slowly and evenly add the above liquids A and B into the colloid mill, and stir for 3 minutes. Then add 4.01 g of attapulgite, continue to stir for 1 min, and transfer the above-mentioned mixed solution to an autoclave with a 500 ml polytetrafluoroethylene liner. Put the reactor into a drying oven at 150°C for hydrothermal crystallization for 12 hours. Then take out the reaction kettle, cool naturally to room temperature, centrifuge and wash to obtain NiFe2O4 / attapulgite composite oxygen carrier particles. After drying naturally in the air, put it in a muffle furnace, raise the temperature from room temperature to 950°C at a rate of 3°C / min a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com