Reactor for hydrogen production through decomposition of hydroiodic acid and hydrogen production method of reactor

A technology of hydroiodic acid and reactors, which is applied in the field of reactors for hydroiodic acid decomposition to produce hydrogen, which can solve the problems of reactor strength and life discount, not being a reactor for hydrogen production, and high sealing requirements, etc., to achieve a hydrogen production method Simple and feasible, good heat transfer performance and low metal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

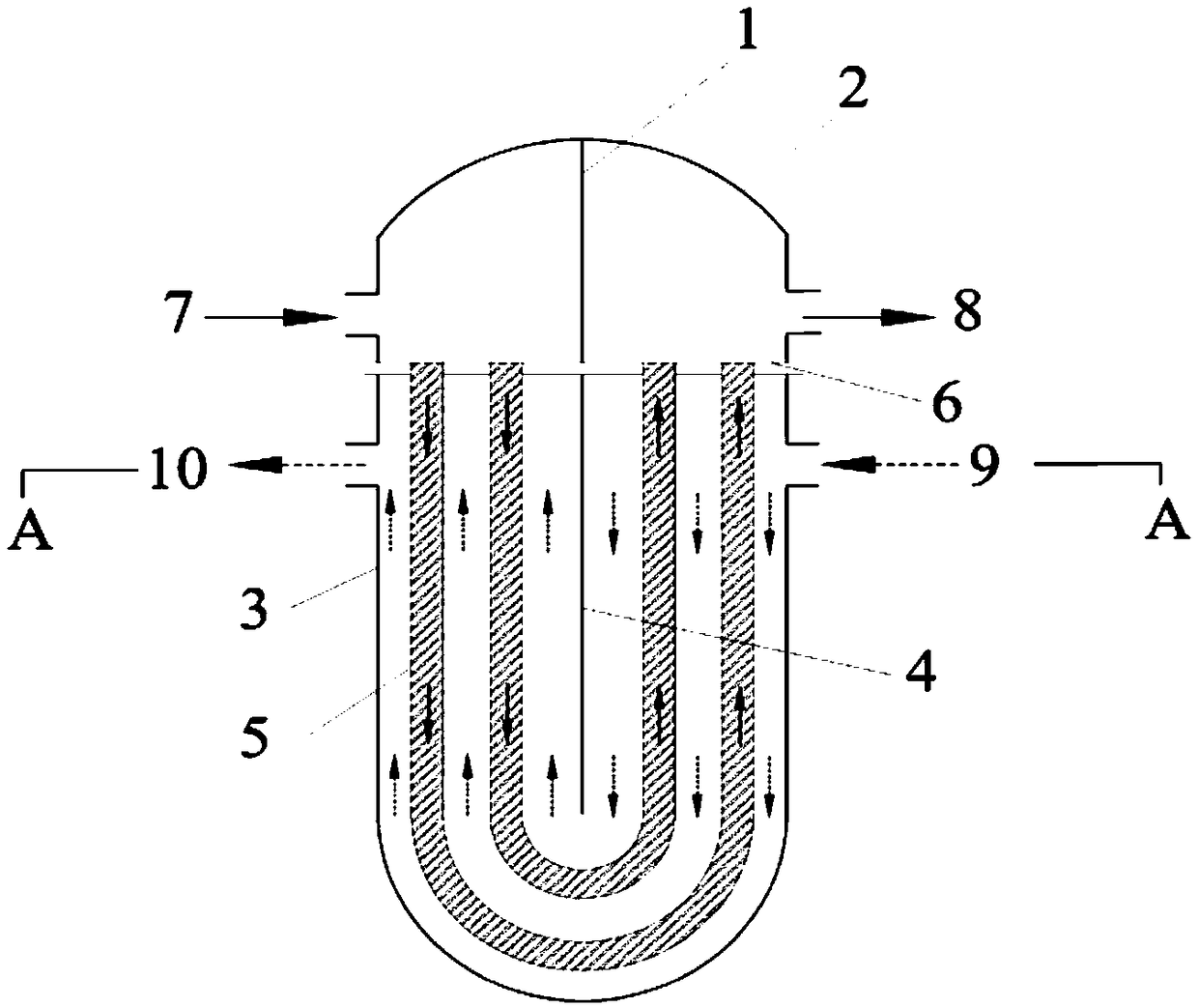

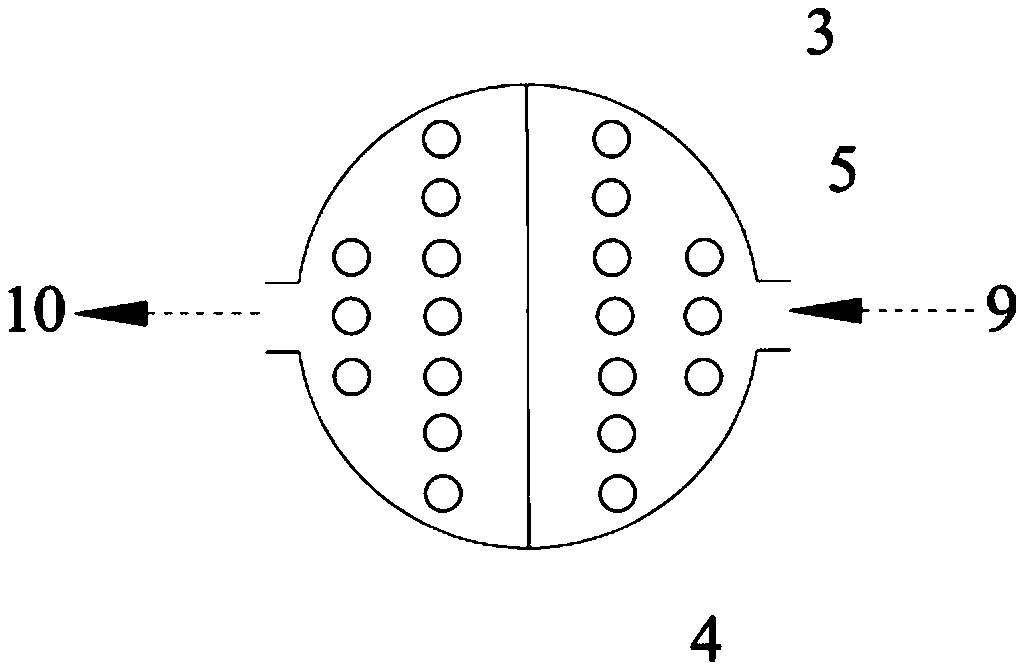

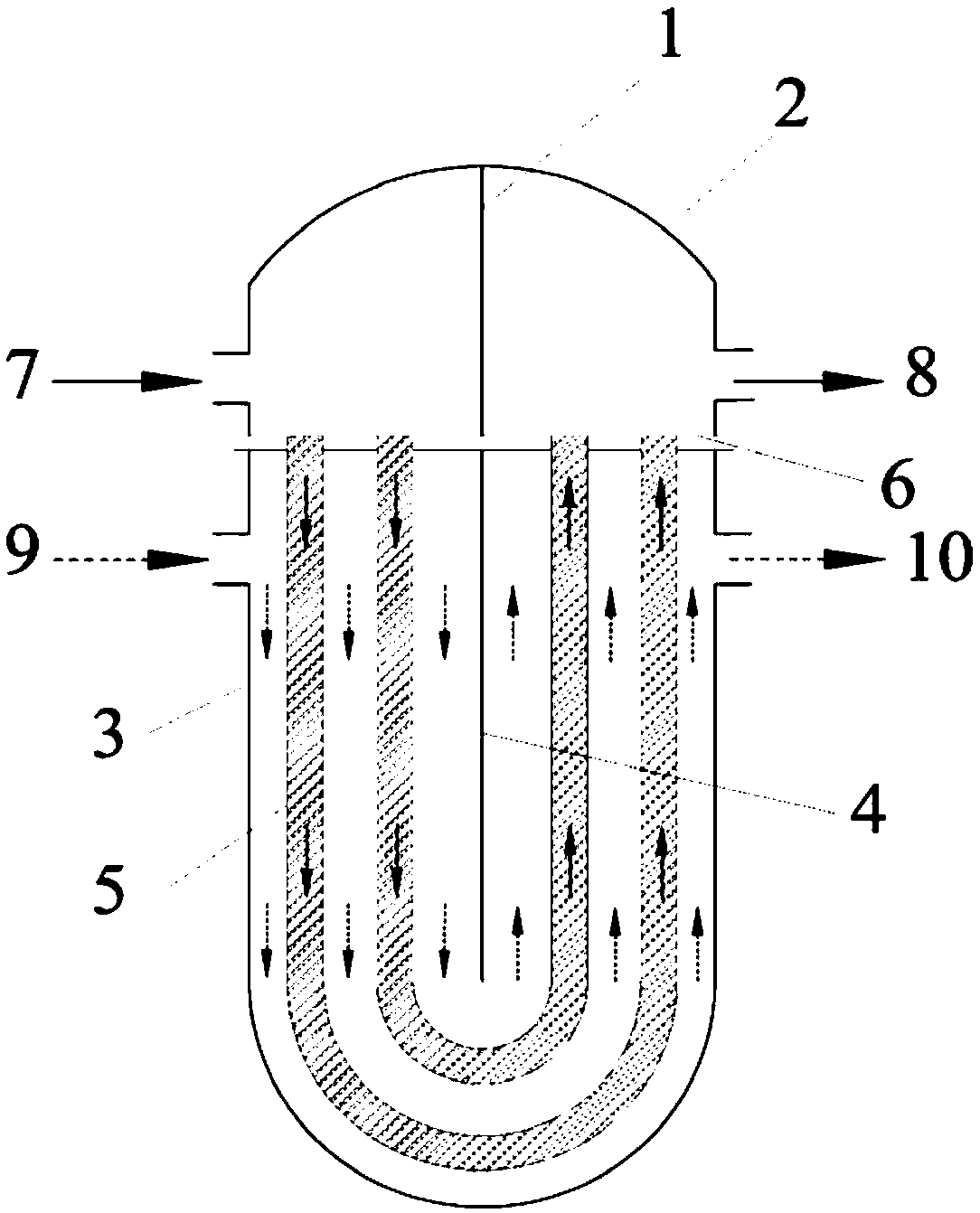

[0033] Adopt the hydrogen iodide decomposition reactor provided by the present invention, its described pipe box, divider plate, tube sheet and U-shaped heat exchange reaction tube are made of corrosion-resistant silicon carbide; Martensitic steel is used as the material for the manufacturing of the vertical and longitudinal partitions. The hydrogen production method by decomposing hydriodic acid is to use the above-mentioned reactor as the hydriodic acid decomposition reactor, place the activated carbon catalyst in the U-shaped heat exchange reaction tube; Helium gas is passed into the cylinder to continuously increase the temperature of the catalyst bed in the U-shaped heat exchange reaction tube to a temperature of 600°C, and the reaction material hydriodic acid: an aqueous solution of hydrogen iodide with a mass concentration of not less than 45% passes through the reaction material The inlet leads into the U-shaped heat exchange reaction tube, and the heating medium in th...

Embodiment 2

[0035] Adopt the hydrogen iodide decomposition reactor provided by the present invention to produce hydrogen, its pipe box, split-pass dividing plate, tube plate and U-shaped heat exchange reaction tube are made of corrosion-resistant nickel-based alloy Hastelloy C-276 for use; Austenitic steel is selected as the material for the cylinder body and the longitudinal partition. The method for producing hydrogen by decomposing hydriodic acid is as follows: the above-mentioned U-shaped tube heat exchange reactor is used as the hydriodic acid decomposition reactor, and the bimetallic Pt-Ir catalyst supported by activated carbon is placed in the U-shaped heat exchange reaction tube; The heating medium at the input port: Helium gas heated by nuclear energy at a temperature of 450°C and a pressure of 10MPa is passed into the cylinder, so that the temperature of the catalyst bed in the U-shaped heat exchange reaction tube is continuously raised to 400°C, and the reaction material is hydr...

Embodiment 3

[0037] Adopt the hydrogen iodide decomposition reactor provided by the present invention to produce hydrogen, its described pipe box, split-pass dividing plate, tube plate and U-shaped heat exchange reaction tube manufacturing material are selected corrosion-resistant Hastelloy B series nickel-based alloys; The above-mentioned barrel and longitudinal partitions are made of Hastelloy X series nickel-based alloys. The method for producing hydrogen by decomposing hydriodic acid is to use the above-mentioned U-shaped tube heat exchange reactor as the hydriodic acid decomposition reactor, place the loaded Pt catalyst in the U-shaped heat exchange reaction tube; : The molten salt heated by nuclear energy at a temperature of 500°C and a pressure of 0.1MPa is passed into the cylinder, so that the temperature of the catalyst bed in the U-shaped heat exchange reaction tube is continuously raised to a temperature of 450°C, and the reaction material hydriodic acid: hydrogen iodide The mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com