Method for preparing elastic expanding silk floss by mulberry silk by-products

A by-product, the technology of mulberry silk, which is applied in the field of silk processing, can solve the problems such as the reduction of silk cotton elasticity, softness and warmth retention, the decrease of silk cotton elasticity and bulkiness and warmth retention performance, and the easy sticking and entanglement of silk cotton fibers. Achieve the effects of improving permeability and mass transfer performance, increasing reproductive capacity, and increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of strain suspension: 25 parts of Candida, 18.5 parts of Bacillus, 18 parts of Lactic Acid Bacteria, 17 parts of Mucor, 12 parts of Thiobacillus denitrifica, and 10 parts of Alcaligenes were used as starting strains. It conducts mutagenesis, the energy of mutagenesis is set to 30kev, and the dose of mutagenesis is 4×1015 ion / cm 2 After the treatment, the mutagenized strains were obtained, and 190 parts of normal saline was added to the mutagenized strains to prepare a strain suspension;

[0029] Preparation of immobilized strains: Mix 9 parts of polyvinyl alcohol and 1.8 parts of sodium alginate, heat in a water bath at 80°C, and keep stirring to prevent cohesion. After the mixture is completely dissolved, add in a mass ratio of 1:1 : 1 corn cob, wheat straw, pine chips as raw materials prepared 6 parts of biochar, 5.5 parts of diatomaceous earth, stirred and mixed evenly, cooled to 30 ° C, then added 3.2 parts of the prepared strain suspension, stirred and ...

Embodiment 2

[0035] Preparation of strain suspension: 20 parts of Candida, 19.5 parts of Bacillus, 15 parts of Lactobacillus, 16 parts of Mucor, 11.5 parts of Thiobacillus denitrifica, and 12 parts of Alcaligenes were used as the starting strains, and ion beam was used to It conducts mutagenesis, the energy of mutagenesis is set to 30kev, and the dose of mutagenesis is 4×10 15 ion / cm 2 After the treatment, the mutagenized strains are obtained, and 200 parts of normal saline are added to the mutagenized strains to prepare a strain suspension;

[0036] Preparation of immobilized strains: Mix 11 parts of polyvinyl alcohol and 1.5 parts of sodium alginate, heat in a water bath at 80°C, and keep stirring to prevent cohesion. After the mixture is completely dissolved, add in a mass ratio of 1:1 : 1 corncob, wheat straw, pine debris prepared as raw materials, 8 parts of biochar, 5 parts of diatomaceous earth, stir and mix evenly, then cool to 30 ° C, then add 3.5 parts of the prepared strain sus...

Embodiment 3

[0042] Preparation of strain suspension: 22 parts of Candida, 18 parts of Bacillus, 16 parts of Lactic Acid Bacteria, 15 parts of Mucor, 10 parts of Thiobacillus denitrifica, and 11 parts of Alcaligenes were used as starting strains. It conducts mutagenesis, the energy of mutagenesis is set to 30kev, and the dose of mutagenesis is 4×10 15 ion / cm 2 After the treatment, the mutagenized strains were obtained, and 180 parts of normal saline was added to the mutagenized strains to prepare a strain suspension;

[0043] Preparation of immobilized strains: Mix 10 parts of polyvinyl alcohol and 1 part of sodium alginate, heat in a water bath at 80°C, and keep stirring to prevent cohesion. After the mixture is completely dissolved, add in a mass ratio of 1:1 : 7 parts of biochar prepared from 1 corncob, wheat straw, and pine chips, and 6 parts of diatomaceous earth were stirred and mixed evenly, then cooled to 30°C, and then 3.8 parts of the prepared strain suspension were added, stirr...

PUM

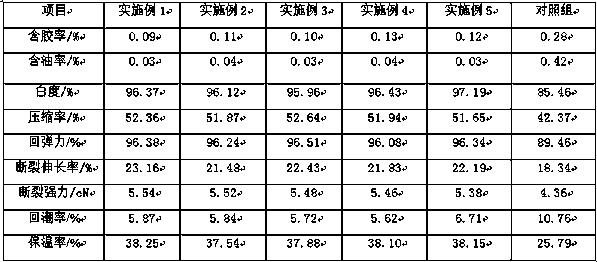

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com