Preparation method of composite structure film with unidirectional fog collection function and application thereof

A composite structure and fog collection technology, applied in the field of chemical bionics, can solve problems such as unsatisfactory needs, complex preparation process, and low water collection efficiency, and achieve increased collision probability and collection speed, strong operability, and good outdoor stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

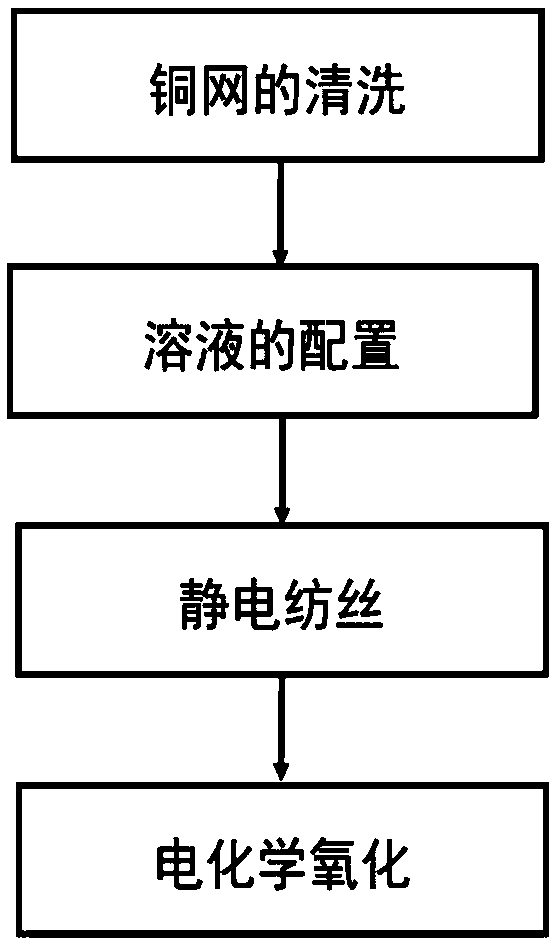

[0033] A kind of preparation method of the composite structure film with one-way fog collection function that the present invention proposes, such as figure 1 As shown, it specifically includes the following steps:

[0034] Step 1: Cleaning of copper mesh:

[0035] Put the copper mesh into ethanol, acetone and deionized water in turn, and ultrasonically clean them for 30 minutes respectively to remove the oil stains and impurities attached to the copper mesh. The aperture size of the selected copper mesh is about 72 μm, and the diameter of the copper wire is about 50 μm.

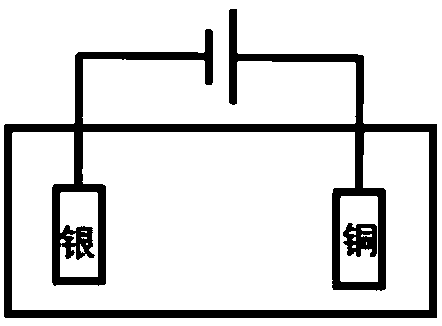

[0036] Step 2: Prepare a polymer solution with a mass fraction of 10-20%, and a potassium hydroxide solution with a concentration of 1.0-3.0mol / L:

[0037] Adding the polymer to the solvent and stirring for more than 5 hours to obtain a polymer solution with a mass fraction of 10-20%; adding potassium hydroxide particles to deionized water to obtain a potassium hydroxide solution with a concentration of 1....

Embodiment 1

[0050] Step 1: Cleaning of copper mesh:

[0051] Cut the copper mesh into a shape of 7cm×10cm, put it into ethanol, acetone, and deionized water in turn, and ultrasonically clean it for 30 minutes respectively to remove oil stains and impurities attached to the copper mesh.

[0052] Step 2: Prepare a polymer solution with a mass fraction of 10%, and a potassium hydroxide solution with a concentration of 1.0mol / L:

[0053] Put 10 parts by weight of polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) into 90 parts by weight of a solvent, and stir for 8 hours to turn it into a polymer solution. The solvent components and mass ratio are acetone (Ac):N,N-dimethylacetamide (DMAc)=9:4, and polyvinylidene fluoride-hexafluoropropylene (PVDF- HFP) solution.

[0054] Put solid potassium hydroxide into deionized water to prepare a 1.0 mol / L potassium hydroxide aqueous solution.

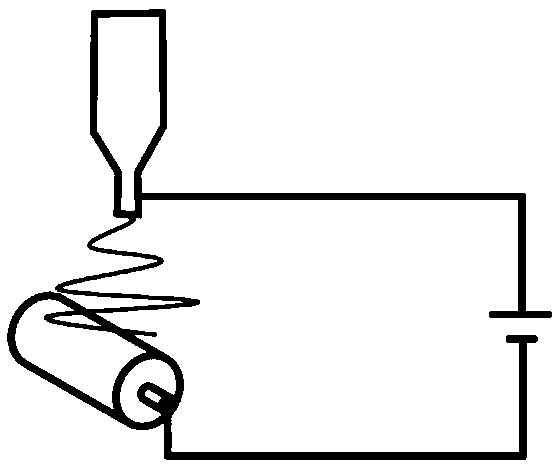

[0055] Step 3: Spinning, covering a layer of polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) fibe...

Embodiment 2

[0061] Step 1: Cleaning of copper mesh:

[0062] Cut the copper mesh into a shape of 7cm×10cm, put it into ethanol, acetone and deionized water in turn, and ultrasonically clean it for 30min respectively. Remove oil stains and impurities attached to the copper mesh.

[0063] Step 2: prepare a polymer solution with a mass fraction of 16%, and a concentration of 2.0mol / L potassium hydroxide solution:

[0064] 16 parts by weight of polytetrafluoroethylene (PTFE) was dissolved in 84 parts by weight of tetrahydrofuran (THF), and stirred for 8 hours to become a polytetrafluoroethylene (PTFE) solution. Put the solid potassium hydroxide into deionized water to prepare a 2.0 mol / L potassium hydroxide aqueous solution.

[0065] Step 3: Spinning, covering a layer of polytetrafluoroethylene (PTFE) fiber membrane on the cleaned copper grid by electrospinning method:

[0066] Paste the cleaned copper net on the center of the roller as the receiving substrate, place the polytetrafluoroeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com