SO2 toxicity-resistant fuel cell oxygen-reduction nobel metal catalyst and preparation method and application thereof

A noble metal catalyst and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as air pollution, Pt catalyzed oxygen reduction reaction activity reduction, etc., to avoid the formation of alloys, improve the anti-SO2 poisoning performance, reduce The effect of competitive adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] An anti-SO 2 The preparation method of the poisoned fuel cell oxygen reduction precious metal catalyst, the specific steps are as follows:

[0048] (1) Synthesis of Ru / C

[0049] ①Put 100mg of carbon powder in a bottle, add 15ml of water, and ultrasonically disperse it at 30°C with 100W power for 20 minutes to obtain a carbon powder slurry;

[0050] ②Take a 250ml beaker and add 150ml of ultrapure water, add the carbon powder slurry of step ① into the beaker, and stir for 10 minutes with a rotor;

[0051] ③Add 540mg of urea to the stirred solution in step ②, and stir for 10 minutes;

[0052] ④ Take 5.577ml of RuCl with a concentration of 53.79mM 3 The aqueous solution is added to the stirred solution in step ③, and stirred for 10 minutes to obtain a mixed solution;

[0053] ⑤ Put the beaker containing the mixed solution in step ④ in a water bath, heat at 90°C for 5 hours, stop heating, and stir to dissipate heat to room temperature;

[0054] ⑥Centrifuge the mixed solution that has b...

Embodiment 2

[0065] Example 2 Ru@Pt / C diffraction results

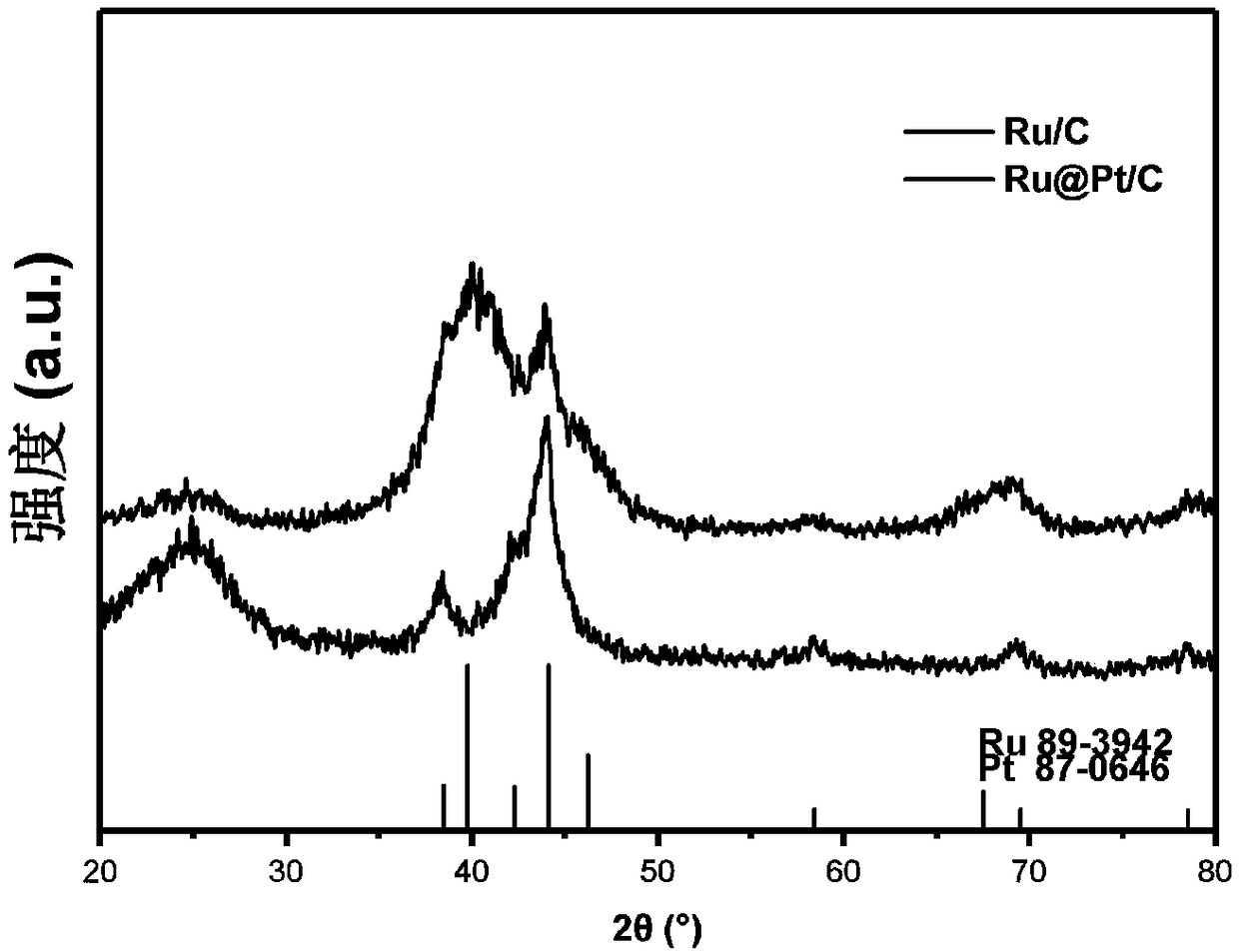

[0066] Diffracting the Ru@Pt / C and Ru / C prepared in Example 1, the XRD pattern results are as follows figure 1 As shown, the diffraction peak of Ru / C corresponds to the standard diffraction peak of Ru, indicating that the prepared Ru / C is a simple substance of Ru. The diffraction pattern of Ru@Pt / C showed the standard diffraction peaks of Pt and Ru, and the position of the diffraction peaks did not shift, indicating that Pt and Ru were not alloyed.

Embodiment 3

[0067] Example 3 Electron microscope observation results of Ru@Pt / C

[0068] The Ru@Pt / C prepared in Example 1 was observed under transmission electron micrograph (TEM) and high resolution transmission electron microscope (High resolution transmission electron microscopy image, HRTEM), the results are as follows Figure 2-4 As shown, it shows that the metal nanoparticles are uniformly distributed, and new lattice fringes appear around the Ru nanoparticles, corresponding to the (111) crystal plane of Pt, indicating that Pt is wrapped on the surface of the Ru nanoparticles to form a Ru@Pt core-shell structure .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com