Mud-resistant polycarboxylate-type water reducing agent and preparation method and application thereof

A polycarboxylic acid-based, mud-resistant technology, applied in the field of cement concrete admixtures, can solve the problems of low working effect of polycarboxylate water reducing agent, low water-reducing efficiency, large slump loss, etc. Layer adsorption, favorable dispersion, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

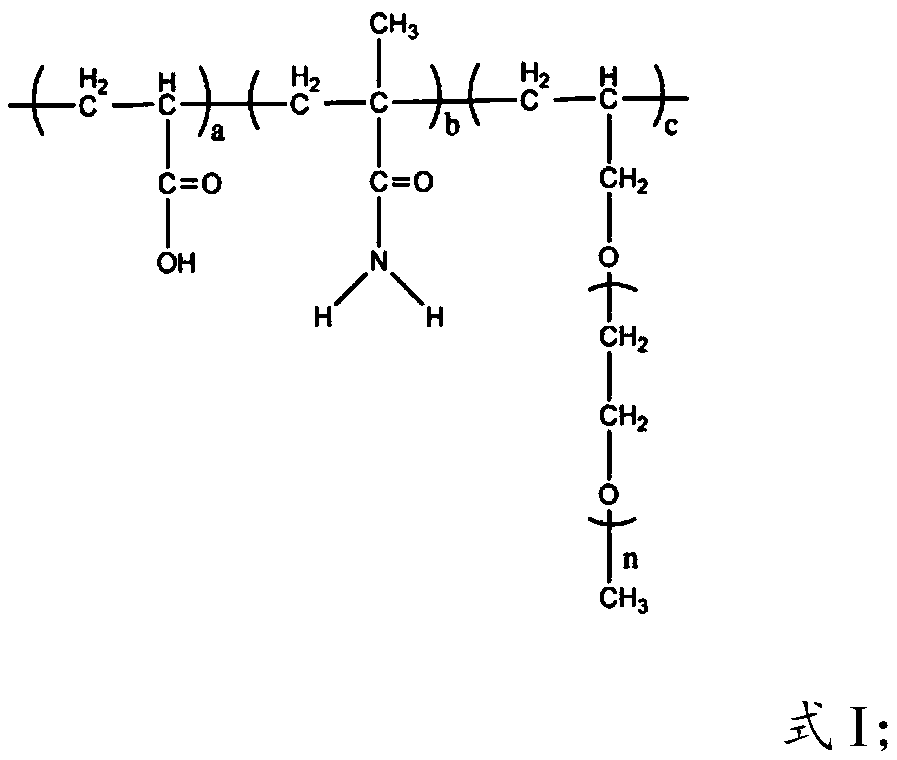

[0032] The present invention also provides a preparation method of the mud-resistant polycarboxylate superplasticizer, comprising the following steps:

[0033] (1) Mix methacrylamide and acrylic acid with water to make mixed solution A; mix allyl polyethylene glycol with water to make solution B; mix initiator and transfer agent with water to make mixed solution Liquid C;

[0034] (2) After mixing the mixed solution A, solution B and mixed solution C, heat them to a first temperature, and perform free radical polymerization to obtain a polymerized product;

[0035] (3) At the first temperature, adjust the pH value of the polymerization product to 6.5-7 to obtain a mud-resistant polycarboxylate water reducer.

[0036] In the present invention, mix methacrylamide and acrylic acid with water to make mixed solution A, mix allyl polyethylene glycol with water to make solution B; mix initiator and transfer agent with water to make Mixture C. In the present invention, there is no ...

Embodiment 1

[0046] Calculated by weight percentage, the mass percentage of acrylic acid, methacrylamide, and allyl polyethylene glycol (polymerization degree 7) is 55:40:100;

[0047] At room temperature, mix methacrylamide and acrylic acid with water to prepare a 50% solution A; mix low-molecular allyl polyethylene glycol with water to prepare a 60% solution B; use acrylic acid, The total amount of methacrylamide and allyl polyethylene glycol is used as a benchmark, and the mass fraction is 1% initiator potassium persulfate and 0.5% mercaptoethanol and water to prepare mixed solution C, mixed solution C The water consumption is 30% of the total water quantity of mixed solution A and solution B.

[0048] Add the mixed solution A, solution B and mixed solution C dropwise into the reaction vessel at a rate of 2ml / min; after heating to 70°C, keep the reaction for 5 hours.

[0049] After the reaction, add dropwise a 30% sodium hydroxide solution while stirring, and adjust the pH value of the...

Embodiment 2

[0051] Calculated by weight percentage, the mass percentage of acrylic acid, methacrylamide, and allyl polyethylene glycol (polymerization degree 7) is 35:25:100;

[0052] At room temperature, mix methacrylamide and acrylic acid with water to prepare a 60% solution A; mix low-molecular propyl polyethylene glycol with water to prepare a 65% solution B; Based on the total amount of allyl acrylamide and allyl polyethylene glycol, the mass fraction is 1.5% initiator potassium persulfate and 2% mercaptoethanol and water are formulated into mixed solution C, and the mixed solution C The water consumption is 30% of the total water content of the mixed solution A and solution B.

[0053] Add the mixed solution A, solution B and mixed solution C dropwise into the reaction vessel at a rate of 2ml / min; after heating to 70°C, keep the reaction for 5 hours.

[0054] After the reaction, add dropwise a 30% sodium hydroxide solution while stirring, and adjust the pH value of the reaction mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com