Application of a 3D Hierarchical Porous Graphene/Polypyrrole Composite Material

A composite material and graphene technology, applied in nanotechnology for materials and surface science, organic compound/hydride/coordination complex catalyst, biochemical fuel cell, etc., can solve the problem of weak microbial affinity, poor electron transfer, Low biomass concentration and other issues, to achieve the effects of easy colonization, low charge transfer resistance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

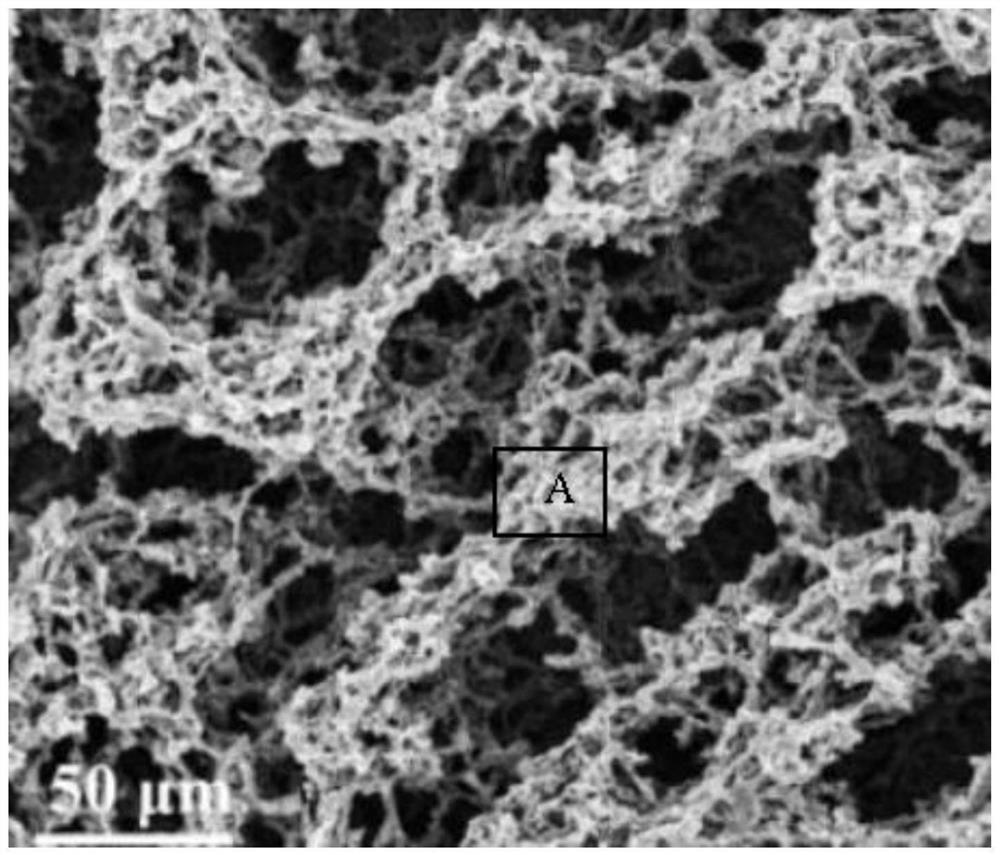

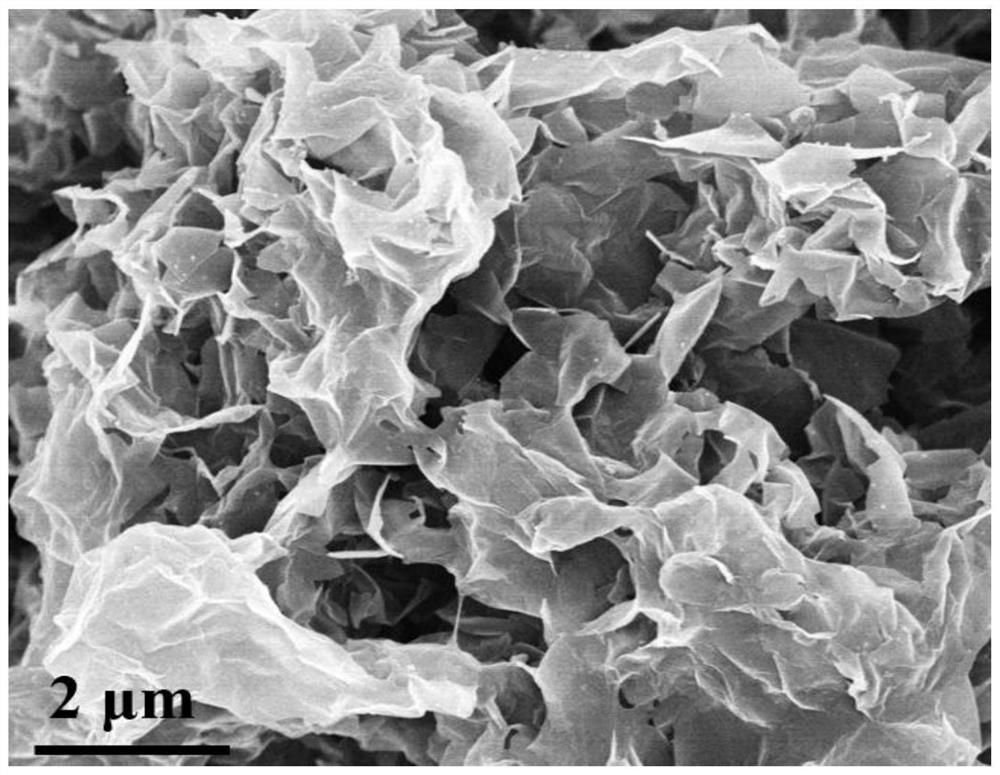

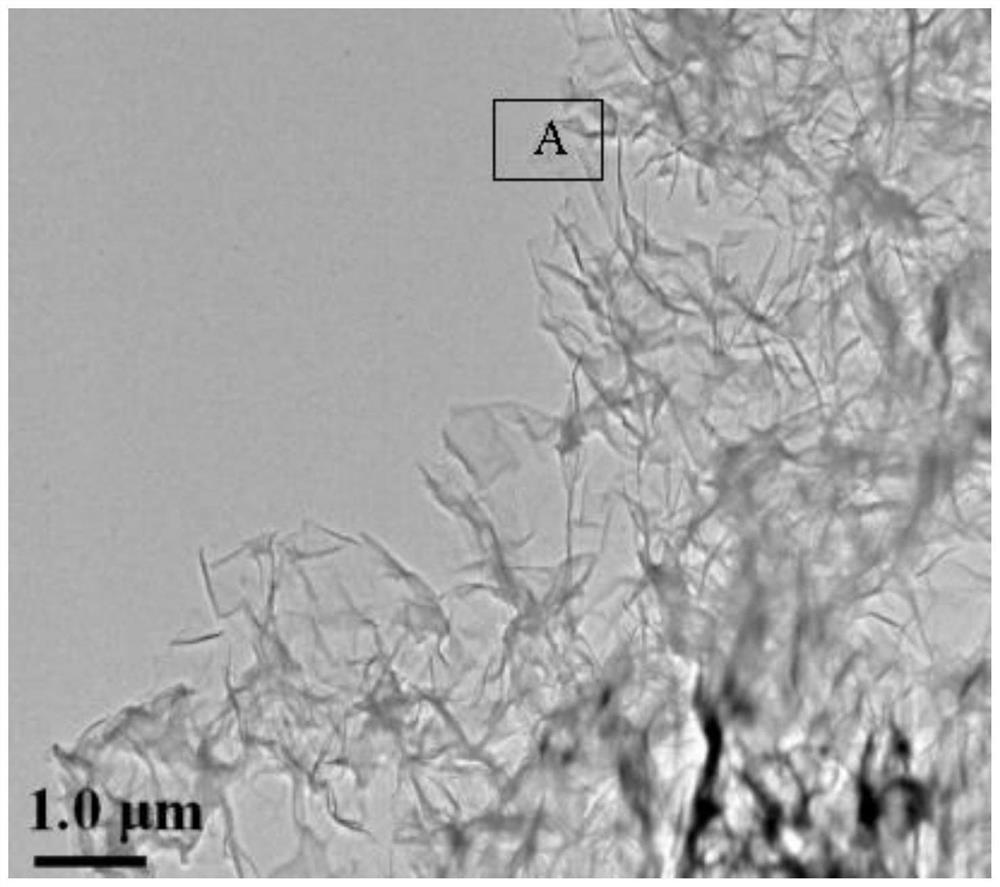

[0026] Specific implementation mode one: the present implementation mode is a kind of preparation method of the graphene / polypyrrole composite material of three-dimensional multilevel hole, specifically is carried out according to the following steps:

[0027] 1. Add the graphene oxide into the citric acid-sodium citrate buffer solution, and ultrasonicate for 3h to 3.5h to obtain a graphene oxide colloidal suspension with a concentration of 0.5g / L to 0.6g / L; the citric acid- The pH of the sodium citrate buffer solution is 3.8 to 4.2;

[0028] 2. Add pyrrole monomer to the graphene oxide colloidal suspension in step 1 to obtain a mixed solution, then use a glassy carbon electrode as a working electrode on an electrochemical workstation, a saturated Ag / AgCl electrode as a reference electrode, and a Pt mesh as For the counter electrode, use the mixed solution as the electrolyte, and conduct cyclic voltammetry deposition for 20 to 22 cycles. The scanning range of cyclic voltammetr...

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the pH of the citric acid-sodium citrate buffer solution described in step 1 is 4. Others are the same as the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the electrochemical workstation described in step 2 is CHI660C. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com