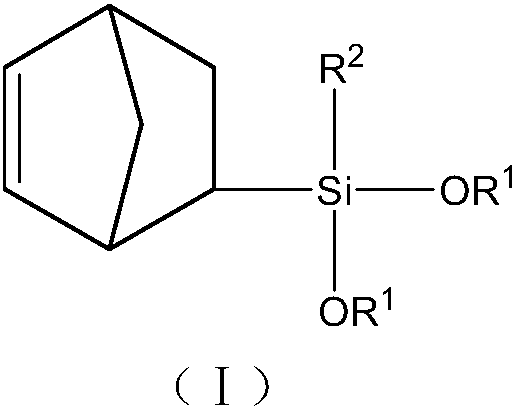

Norbornene base organic group dialkoxy silane compound, preparation method and application thereof

A technology of alkenyl organo dialkoxy silane and alkenyl isobutyl dimethoxy silane is applied in the application field of olefin polymerization catalyst components to achieve the effects of high activity, good comprehensive performance and guaranteed market supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of norbornenyltrimethoxysilane

[0046] In a 1L stainless steel autoclave equipped with a mechanical stirrer, a thermometer, a nitrogen inlet, a feeding port, and a liquid sampling port, add 153.8 g (1.017 mol) of vinyltrimethoxysilane, 80 g (0.593 mol) of dicyclopentene, and methanol 300g, under stirring, the reaction material was heated up to 180°C, and kept for 5 hours. Samples were taken for gas chromatographic analysis to monitor the extent of the reaction. After the reaction is completed, the solvent, unreacted raw materials such as cyclopentadiene, dicyclopentadiene, vinyltrimethoxysilane, etc. are distilled off at normal pressure, and then collected by distillation at -0.098MPa under reduced pressure at 135-156°C The distillate product is 230 grams, and the yield is 75% (based on vinyltrimethoxysilane). The reaction process is:

[0047]

Embodiment 2

[0049] Preparation of norbornenylcyclopentyldimethoxysilane

[0050] Replace the air with nitrogen in a 500ml dry four-necked flask equipped with an electric stirrer, a thermometer, a reflux condenser, and a constant pressure dropping funnel, and drop 12.1g (purity 99%, 0.5mol) particle size into the reaction flask under a nitrogen atmosphere. Magnesium powder less than 100 meshes, 2.7g (purity 99%, 0.026mol) chlorocyclopentane, 20ml methyl tert-butyl ether. A mixture of 51.2 g (0.49 mol) of chlorocyclopentane and 200 ml of methyl tert-butyl ether was added to the constant pressure dropping funnel. Add 0.05 g of initiator iodine to the contents of the reaction vial. After the reaction is initiated, stir. When the exothermic reaction is stable, add the mixture in the dropping funnel dropwise to the reaction flask within 30-60 minutes, and control the reaction temperature so that the solvent is in a reflux state; the mixture of chlorocyclopentane and methyl tert-butyl ether A...

Embodiment 3

[0056] Preparation of norbornenylisobutyldimethoxysilane

[0057] According to the conditions of Example 2, the chlorocyclopentane was replaced by an equimolar chloroisobutane; after the reaction was completed, the solvent was recovered by filtration, washing, normal pressure and the previous fraction was evaporated, and finally the vacuum distillation collected 118-120 ° C / -0.098MPa fraction. 80 g of norbornenyl isobutyldimethoxysilane was obtained with a purity of 98% and a yield of 72% (based on norbornenyl trimethoxysilane). The reaction process is:

[0058]

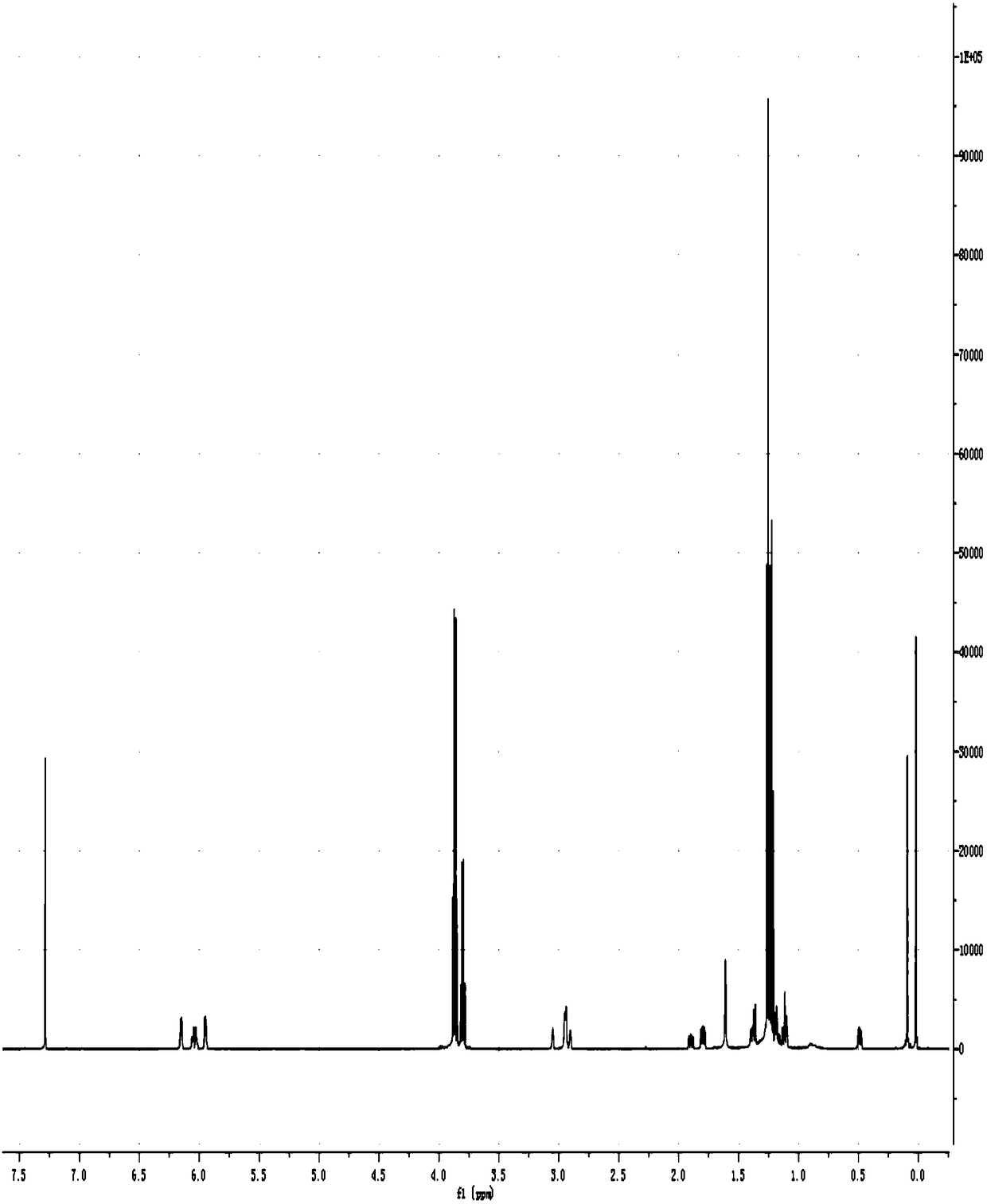

[0059] The hydrogen spectrum result of norbornenyl isobutyl dimethoxysilane compound is:

[0060] 1 H NMR (600MHz, CDCl 3 )δ6.28–5.84(m,2H),3.68–3.42(m,6H),3.13–2.80(m,2H),2.31–1.07(m,6H),0.99(ddd,J=18.1,7.8,3.2 Hz,6H),0.72–0.52(m,2H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com