A kind of low harm thickened acid and its preparation method and application

A technology of thickening acid and acid liquid thickener, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of damage to the formation, easy residue, poor temperature resistance and salt resistance, etc., to achieve small formation damage, Easy to break glue, good effect of thickening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A low-damage thickened acid, its components by mass fraction: acid thickener 4%, acidification corrosion inhibitor 1%, iron ion stabilizer 1%, hydrochloric acid 18%, calculated as pure acid, and the rest is water;

[0024] The acid thickener is a mixture of oleamidopropyl dimethylamine (FLY) and hexadecyl dimethyl tertiary amine (FL16), with a mass ratio of 2.75:1.25;

[0025] The iron ion stabilizer is a mixture of citric acid and sodium isotretinoin with a mass ratio of 4:1.

[0026] The preparation method of low-harm thickened acid is realized through the following steps:

[0027] Mix the mixture of oleamidopropyl dimethylamine (FLY) and hexadecyl dimethyl tertiary amine (FL16) with the acid solution in the container evenly in proportion, then add 1% acidification corrosion inhibitor and 1% iron in sequence Ionic stabilizer, after mixing, stir evenly to form a thickened acid solution.

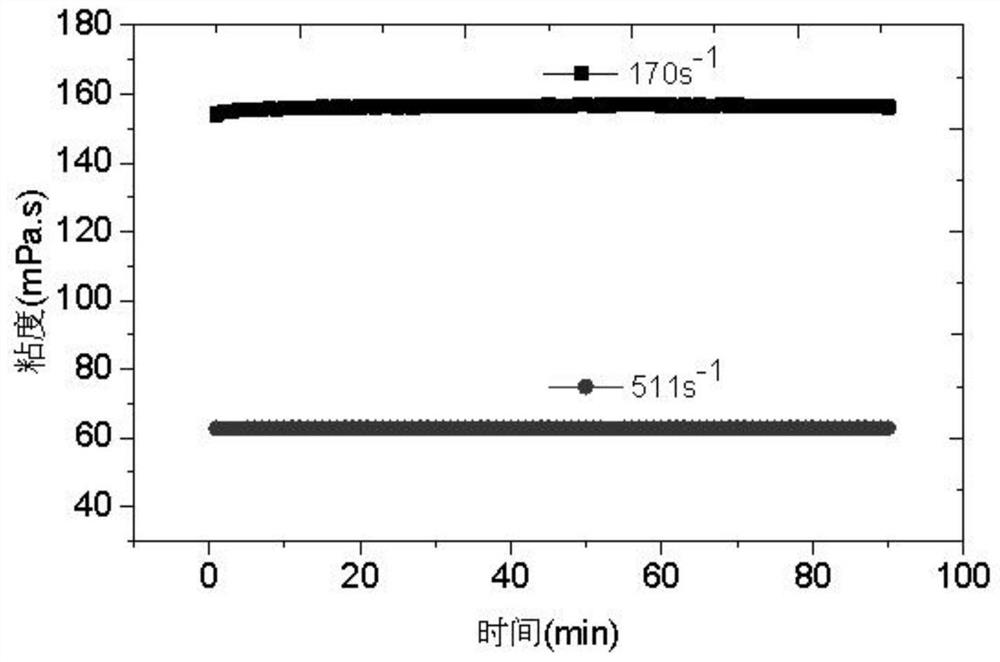

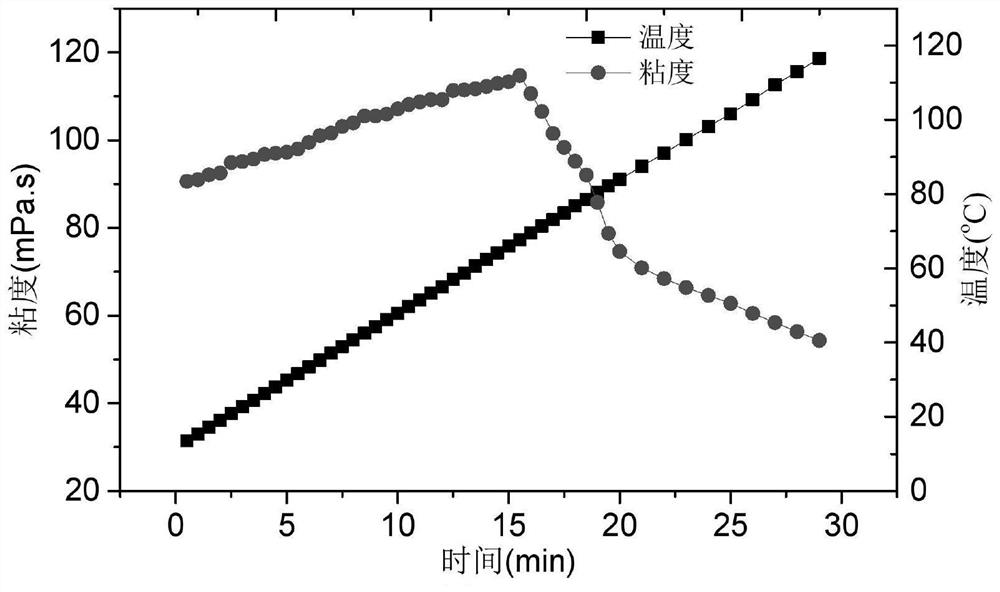

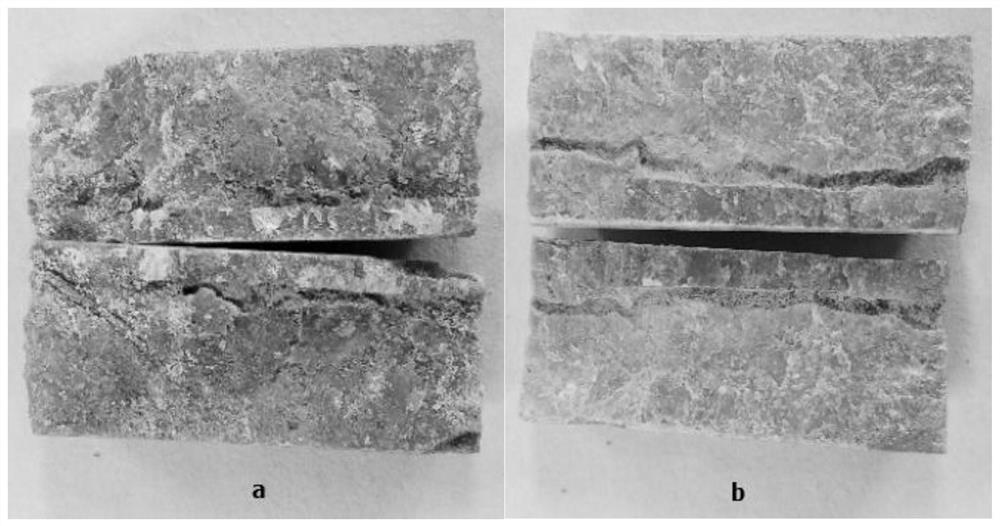

[0028] On the HAKKE MARSⅢ rheometer, the product in embodiment 1 is evaluated f...

Embodiment 2

[0031] A low-damage thickened acid, its components by mass fraction: 2% acid thickener, 2% acidification corrosion inhibitor, 2% iron ion stabilizer, 18% hydrochloric acid, calculated as pure acid, and the rest is water;

[0032] The acid thickener is a mixture of oleamidopropyl dimethylamine (FLY) and hexadecyl dimethyl tertiary amine (FL16), with a mass ratio of 2.75:1.25;

[0033] The iron ion stabilizer is a mixture of citric acid and sodium isotretinoin with a mass ratio of 4:1.

[0034] The preparation method of low-harm thickened acid is realized through the following steps:

[0035] Mix the mixture of oleyl amidopropyl dimethylamine (FLY) and hexadecyl dimethyl tertiary amine (FL16) with the acid solution in the container evenly, then add 2% acidification corrosion inhibitor and 2% iron in sequence Ionic stabilizer, after mixing, stir evenly to form a thickened acid solution.

[0036] On the HAKKE MARSⅢ rheometer, the product in embodiment 2 is evaluated for shear st...

Embodiment 3

[0038] A low-damage thickened acid, its components by mass fraction: acid thickener 3%, acidification corrosion inhibitor 2%, iron ion stabilizer 1%, hydrochloric acid 15%, calculated as pure acid, and the rest is water;

[0039] The acid thickener is a mixture of oleamidopropyl dimethylamine (FLY) and hexadecyl dimethyl tertiary amine (FL16), with a mass ratio of 2.5:1.5;

[0040] The iron ion stabilizer is a mixture of citric acid and sodium isotretinoin with a mass ratio of 4:1.

[0041] The preparation method of low-harm thickened acid is realized through the following steps:

[0042] Mix the mixture of oleamidopropyl dimethylamine (FLY) and hexadecyl dimethyl tertiary amine (FL16) with the acid solution in the container evenly, then add 2% acidification corrosion inhibitor and 1% iron in sequence Ionic stabilizer, after mixing, stir evenly to form a thickened acid solution.

[0043] On the HAKKE MARSⅢ rheometer, the product in embodiment 3 is evaluated for shear stabili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com