Blueberry fruit wine brewing technology

A blueberry fruit wine and blueberry technology, applied in the field of wine making, can solve the problems of reducing wine quality, wine rancidity, reducing the palatability of wine, etc., and achieve the effect of ensuring freshness and pollution-free, sweet taste and retaining nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

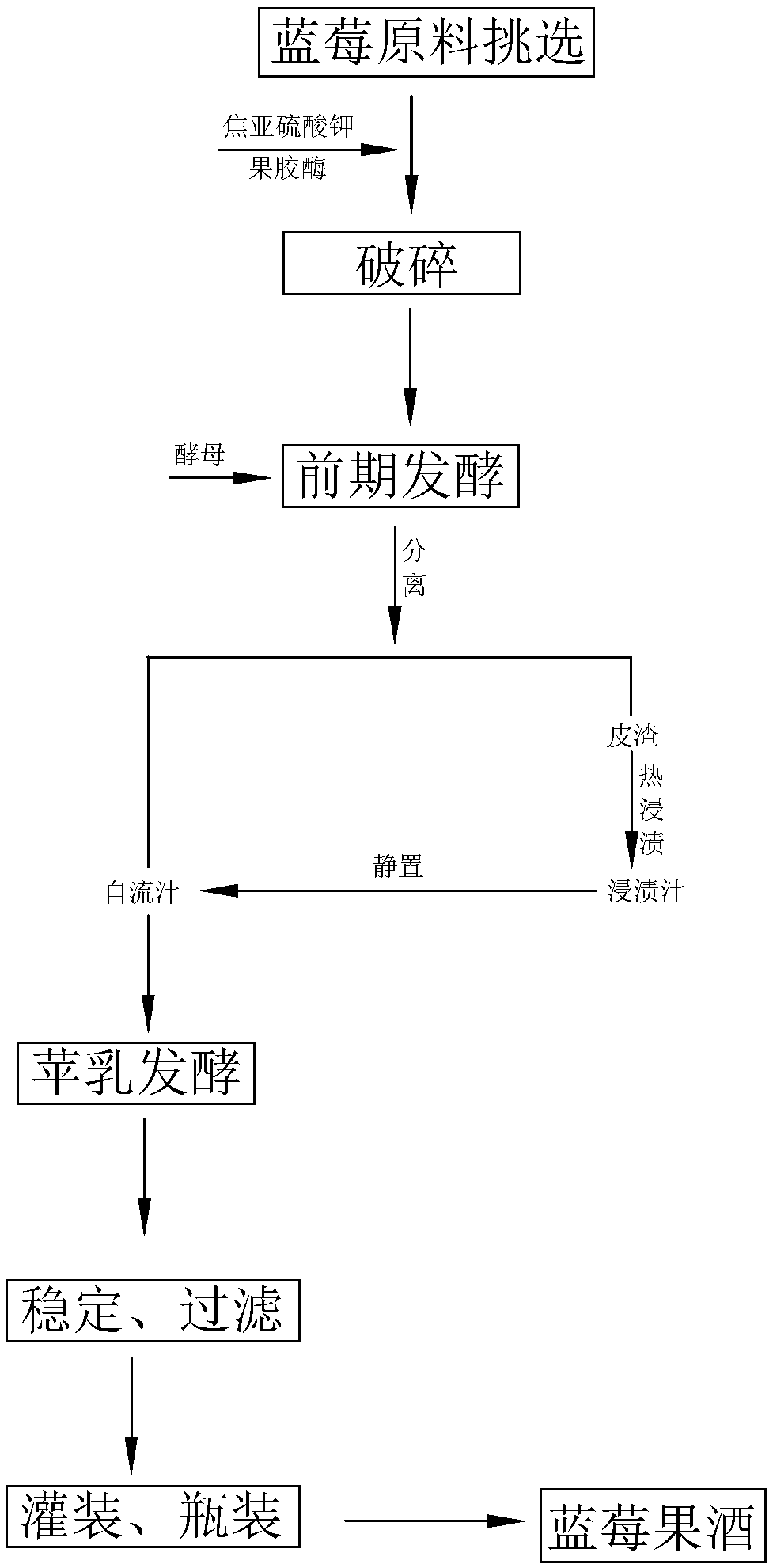

Image

Examples

Embodiment 1

[0028] A blueberry fruit wine brewing process, comprising the following steps:

[0029] S1. Selection of blueberry raw materials: The blueberry raw materials are selected from the wild blueberries in Xiaoxing’an Mountains in Northeast China. They are hand-picked, and then stored in a cold storage at -10°C and transported to the processing site at low temperature; , keeping blueberries in CO 2 In the atmosphere, the blueberries are placed in a container with dry ice, and after the blueberries are placed in the container, the container is evacuated and supplemented with CO 2 ;

[0030] After the blueberries enter the processing place, they are selected, and the green fruit, moldy and rotten fruit particles, that is, dry shriveled fruit particles and blueberry branches and leaves are removed, so that the mature blueberry raw materials enter the next process;

[0031] S2, crushing: carry out crushing process to blueberry raw material, when crushing, with blueberry 1t as referenc...

Embodiment 2

[0041] A kind of blueberry fruit wine brewing process, carries out according to the operation step in embodiment 1, difference is,

[0042] Step S1 During the selection of blueberry raw materials, the picked blueberries are stored in a cold storage at -7°C and transported at this temperature;

[0043] Taking 1t of blueberries as a reference in step S2 crushing, add potassium metabisulfite 70g / t and pectinase 25g / t;

[0044] S3. Pre-fermentation: The pre-fermentation is realized through a fermenter. Taking 1 ton of blueberries as a reference, add 200g / t of Saccharomyces cerevisiae to the raw material obtained after destemming and crushing, and carry out fermentation. The fermentation temperature is 28°C, and the fermentation time is 12 days. During the fermentation process, the volatile acid is controlled at 0.3g / L. When the specific gravity of the fermentation liquid reaches 0.995, the fermentation is terminated;

[0045] After the fermentation, separate the wine liquid to ob...

Embodiment 3

[0053] A kind of blueberry fruit wine brewing process, carries out according to the operation step in embodiment 1, difference is,

[0054] Step S1 During the selection of blueberry raw materials, the picked blueberries are stored in a cold storage at -4°C and transported at this temperature;

[0055] In step S2 crushing, taking 1t of blueberries as a reference, add potassium metabisulfite 85g / t and pectinase 30g / t;

[0056] S3. Pre-fermentation: The pre-fermentation is realized by a fermenter. Taking 1 ton of blueberries as a reference, add 250g / t of Saccharomyces cerevisiae to the raw material obtained after destemming and crushing, and carry out fermentation. The fermentation temperature is 30°C and the fermentation time is 15 days. During the fermentation process, the volatile acid is controlled at 0.5g / L, and when the specific gravity of the fermentation broth reaches 0.998, the fermentation is terminated;

[0057] After the fermentation, separate the wine liquid to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com