Manganous-manganic oxide self-supporting composite electrode as well as preparation method and application thereof

A technology of trimanganese tetraoxide and composite electrodes, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., and can solve problems such as non-self-supporting electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

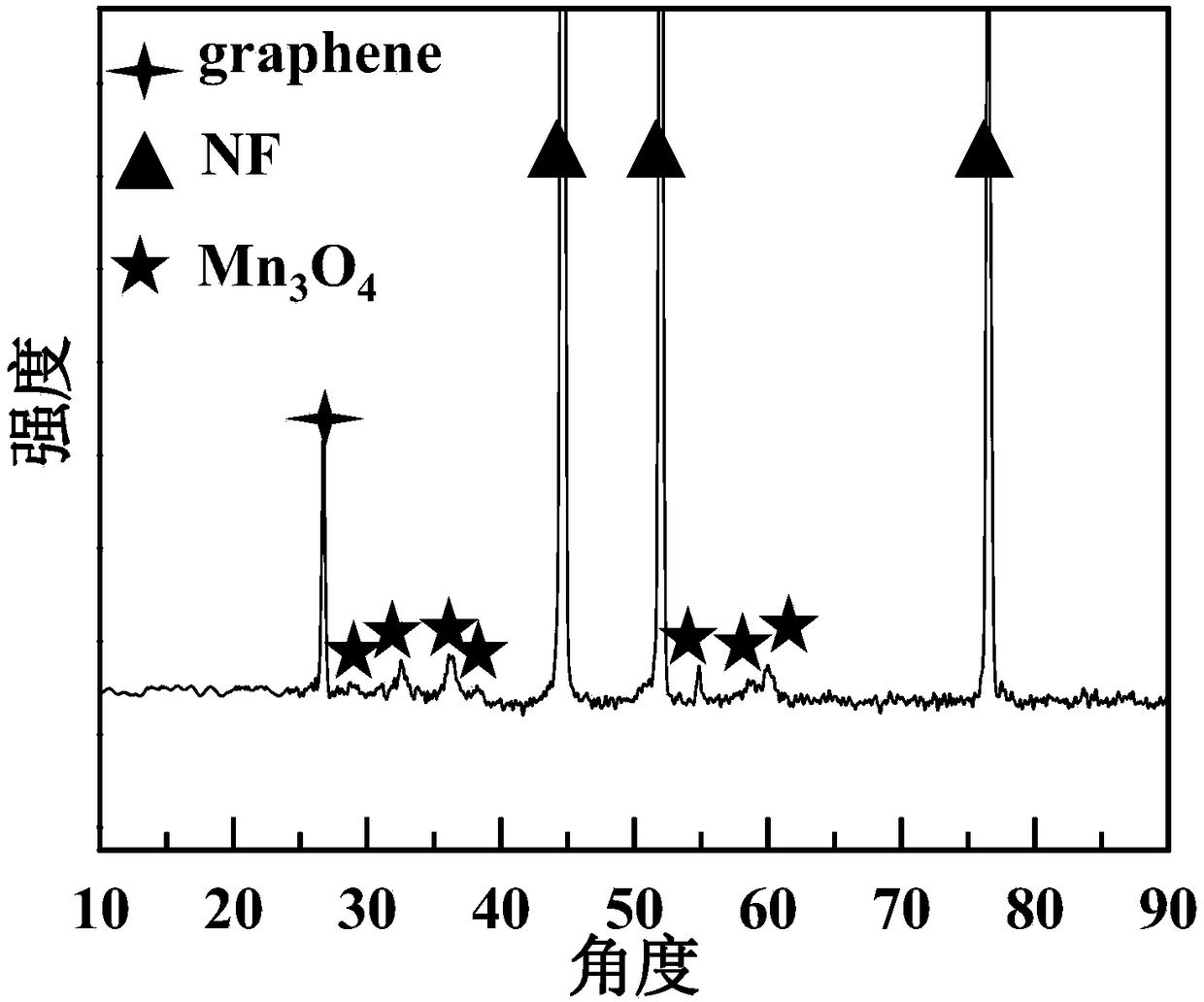

Image

Examples

Embodiment 1

[0020] (1) Cut foam nickel (NF) into shaped structure, put it into a beaker, add acetone, and ultrasonically clean it for 10 minutes in an ultrasonic cleaner. Then, put it in a vacuum drying oven at 80°C for 24 hours;

[0021] (2) Place the NF in (1) in a flat-bottomed crucible, then put the crucible into a high-temperature tube furnace, evacuate the tube furnace, and feed Ar (200 sccm) and H 2 (100sccm), the high temperature tube furnace program is set to 50 ℃ min -1 The temperature was raised to 1000°C at a rate of 10 minutes, and then CH 4 (100sccm), followed by constant temperature for 1h, after reaching the time, turn off H 2 and CH 4 , after cooling down to room temperature naturally, turn off the Ar to get nickel foam / graphene (NF / graphene electrode)

[0022] (3) Configure the mixed solution of 0.5M manganese chloride and 0.5M potassium nitrate as the electrolyte, use the prepared nickel foam / graphene electrode as the working electrode, the platinum sheet as the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com