High-voltage lithium cobalt oxide positive electrode material and preparation method thereof

A cathode material, lithium cobalt oxide technology, used in battery electrodes, circuits, electrical components, etc., can solve problems such as internal structure collapse, rate deterioration, and accelerated reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

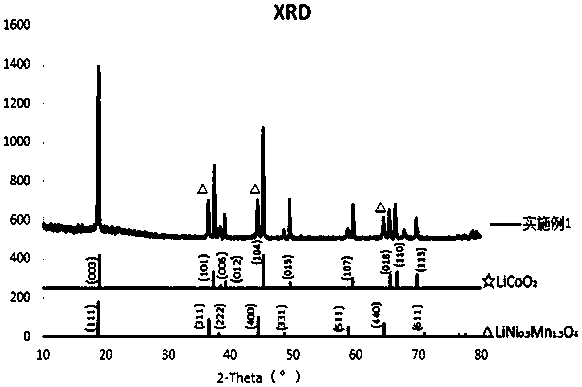

Image

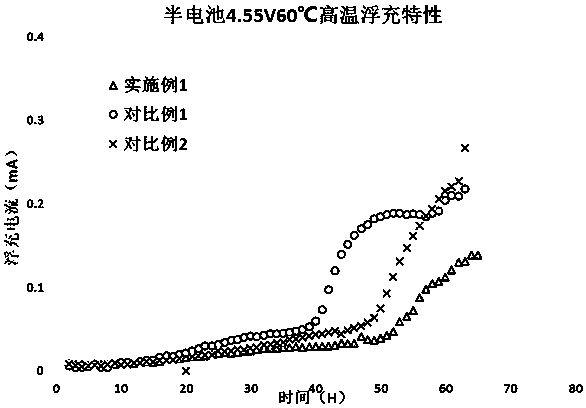

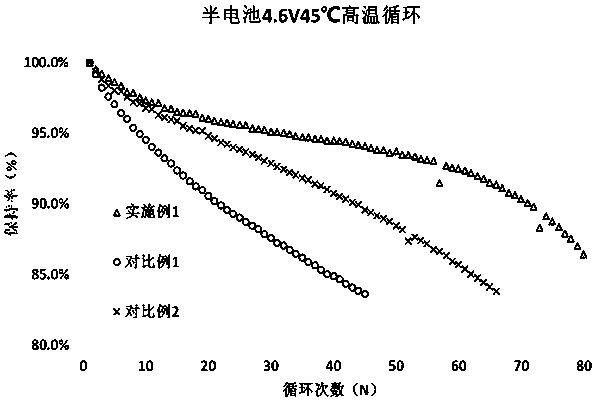

Examples

Embodiment 1

[0030] Prepare 475L of cobalt chloride solution with a concentration of 2mol / L, prepare 20L of nickel-manganese nitrate binary mixed solution with a concentration of 2mol / L (Ni:Mn=1:3), and prepare 20L of lanthanum nitrate solution with a concentration of 0.5mol / L , prepare a sodium carbonate solution with a concentration of 2mol / L as a precipitant. The cobalt nitrate solution, the nickel-manganese binary solution and the sodium carbonate solution are put into different containers respectively, and the cobalt nitrate solution is put into a stirring container.

[0031] The nickel-manganese binary solution is continuously added to the cobalt nitrate solution, and stirred to obtain a mixed salt solution, and at the same time, the mixed salt solution and the sodium carbonate solution are co-flowed into a stirred reactor for reaction to obtain a precursor slurry. During the whole reaction process, the reaction temperature was 50° C., and the reaction time was 20 h. The precursor s...

Embodiment 2

[0035] Prepare 970L of cobalt sulfate solution with a concentration of 1mol / L, prepare 20L of nickel-manganese sulfate binary mixed solution with a concentration of 1mol / L (Ni:Mn=1:3), prepare 50L of yttrium nitrate solution with a concentration of 0.2mol / L, A sodium carbonate solution with a concentration of 1 mol / L was prepared as a precipitating agent. The cobalt sulfate solution, the nickel-manganese binary solution and the sodium carbonate solution are put into different containers respectively, and the cobalt sulfate solution is put into a container with stirring.

[0036]The nickel-manganese binary solution is continuously added to the cobalt sulfate solution, and stirred to obtain a mixed salt solution, and at the same time, the mixed salt solution and sodium carbonate solution are co-flowed into a stirred reactor for reaction to obtain a precursor slurry. During the whole reaction process, the reaction temperature was 40° C., and the reaction time was 30 h. The precu...

Embodiment 3

[0040] Prepare 186L of cobalt acetate solution with a concentration of 0.5mol / L, prepare 12L of nickel-manganese acetate binary mixed solution with a concentration of 0.5mol / L (Ni:Mn=1:3), and prepare a samarium nitrate solution with a concentration of 0.1mol / L 10L, prepare a sodium carbonate solution with a concentration of 0.5mol / L as a precipitant. The cobalt acetate solution, the nickel-manganese binary solution and the sodium carbonate solution are put into different containers respectively, wherein the cobalt acetate solution is put into a container with stirring.

[0041] The nickel-manganese binary solution is continuously added to the cobalt acetate solution, and stirred to obtain a mixed salt solution, and at the same time, the mixed salt solution and sodium carbonate solution are co-flowed into a stirred reactor for reaction to obtain a precursor slurry. During the whole reaction process, the reaction temperature was 60° C., and the reaction time was 50 h. The prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com