The preparation method of lithium magnesium silicate

A technology of lithium magnesium silicate and magnesium sulfate, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as uneven chelation degree of lithium magnesium silicate, unstable batch quality, and hard texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

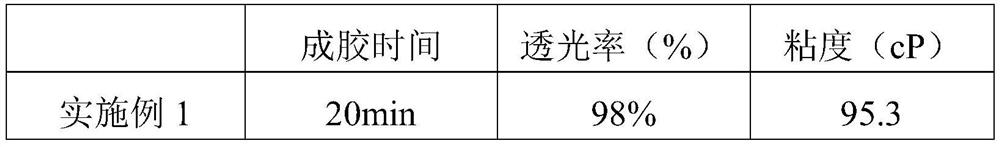

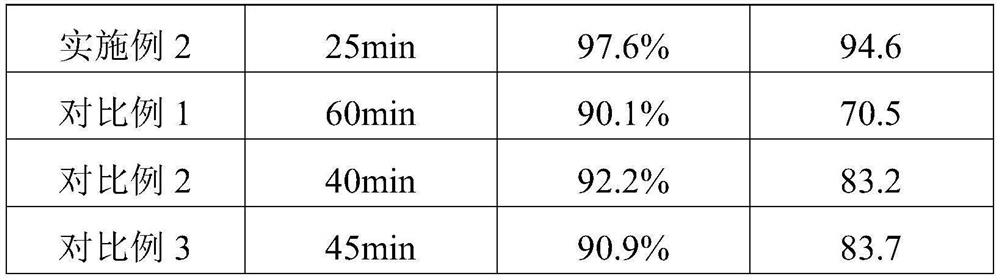

Examples

preparation example Construction

[0022] A kind of preparation method of lithium magnesium silicate is provided in the specific embodiment of the present invention, comprises the following steps:

[0023] (1) In a reaction kettle, dissolve lithium chloride in water, heat to boiling, and keep boiling for 2 to 4 minutes; add magnesium sulfate solution, and keep boiling for 18 to 22 minutes; preferably, in the lithium chloride and magnesium sulfate, The molar ratio of lithium to magnesium is (0.9~1.1):1; (2) Liquid water glass is added dropwise to the reactor at a constant speed; preferably, the speed of said constant dropwise addition is: 0.4kg / min~0.6kg / min min; (3) Add the sodium carbonate solution dropwise to the reaction kettle at a constant speed; (4) After the dropwise addition, keep boiling and react for 17-20 hours to obtain the product;

[0024] Further preferably, the molar ratio of the silicon, lithium and magnesium is (2-4):(0.9-1.1):1; the molar ratio of the sodium carbonate to the lithium chloride ...

Embodiment 1

[0030] This embodiment provides a kind of preparation method of lithium magnesium silicate, and main raw material comprises:

[0031] Food grade magnesium sulfate heptahydrate (MgSO 4 ·7H 2 O), water glass (liquid, water-soluble sodium silicate, modulus ratio is 3), lithium chloride (LiCl), edible sodium carbonate (Na 2 CO 3 );

[0032] The preparation steps are as follows:

[0033] a. Completely dissolve 29.6kg of magnesium sulfate heptahydrate with 130kg of deionized water, and set aside.

[0034] b. In a 1000L reaction kettle containing a condensing reflux system and a heating system, add 5.18kg of lithium chloride, add 50kg of water, heat and stir, and keep boiling for 3 minutes, then add magnesium sulfate solution, keep boiling for 20 minutes, and the reaction kettle is at Keep boiling and stirring continuously throughout the production process.

[0035] c. Add 36.65kg of water glass into the dropping tank, and evenly add it dropwise in the reaction kettle, and cont...

Embodiment 2

[0042] This embodiment provides a preparation method of lithium magnesium silicate. The raw material and preparation method are basically the same as in Example 1, and the difference is that, among the raw materials used, the modulus ratio of water glass is 4. The remaining raw materials, preparation steps and conditions are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com