Production method for synthesizing high molecular weight nylon 9T resin from low molecular weight nylon 9T powder

A low-molecular-weight nylon and high-molecular-weight technology, which is applied in the polymer field, can solve the problems of unreachable nylon 9T chemical properties, mechanical properties, thermal properties, unreachable molding conditions, and wide molecular weight distribution, and achieves easy automation and control. Good chemical properties, easy to operate and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: A kind of production method of low molecular weight nylon 9T powder condensation polymerization into high molecular weight nylon 9T resin

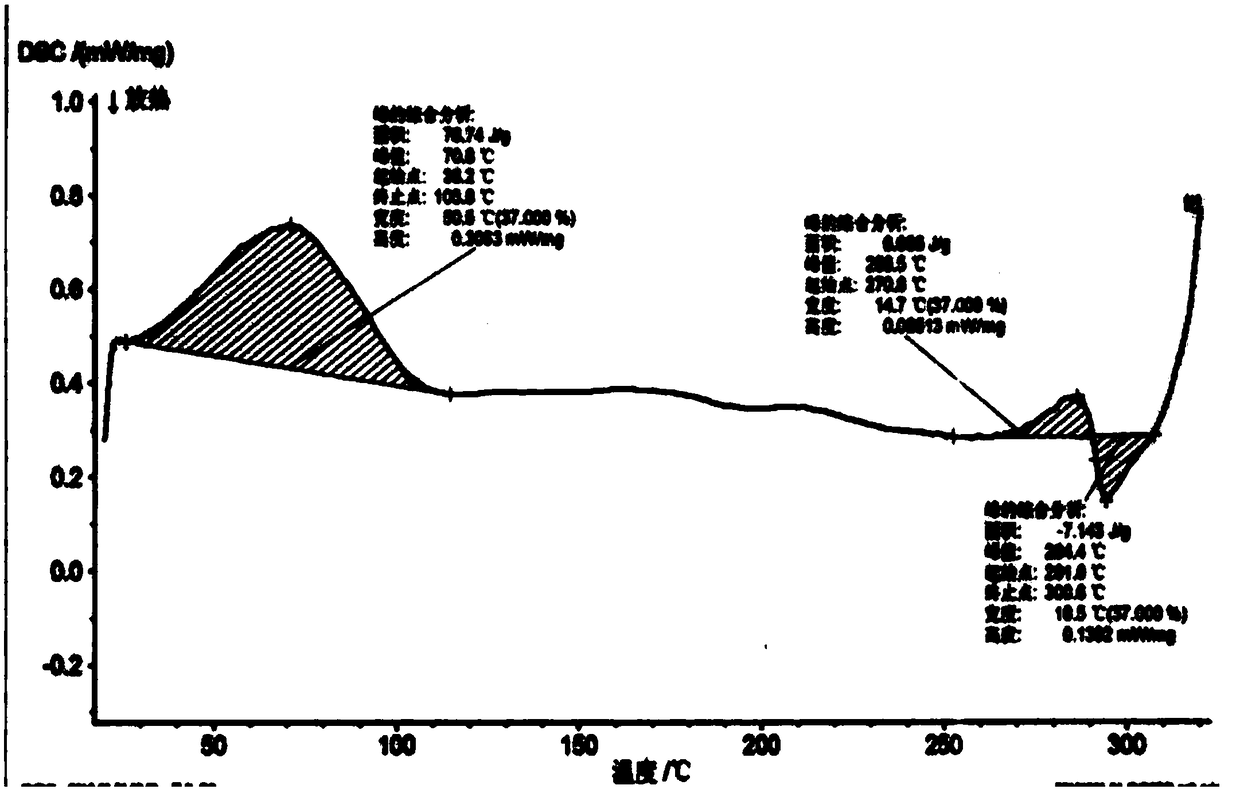

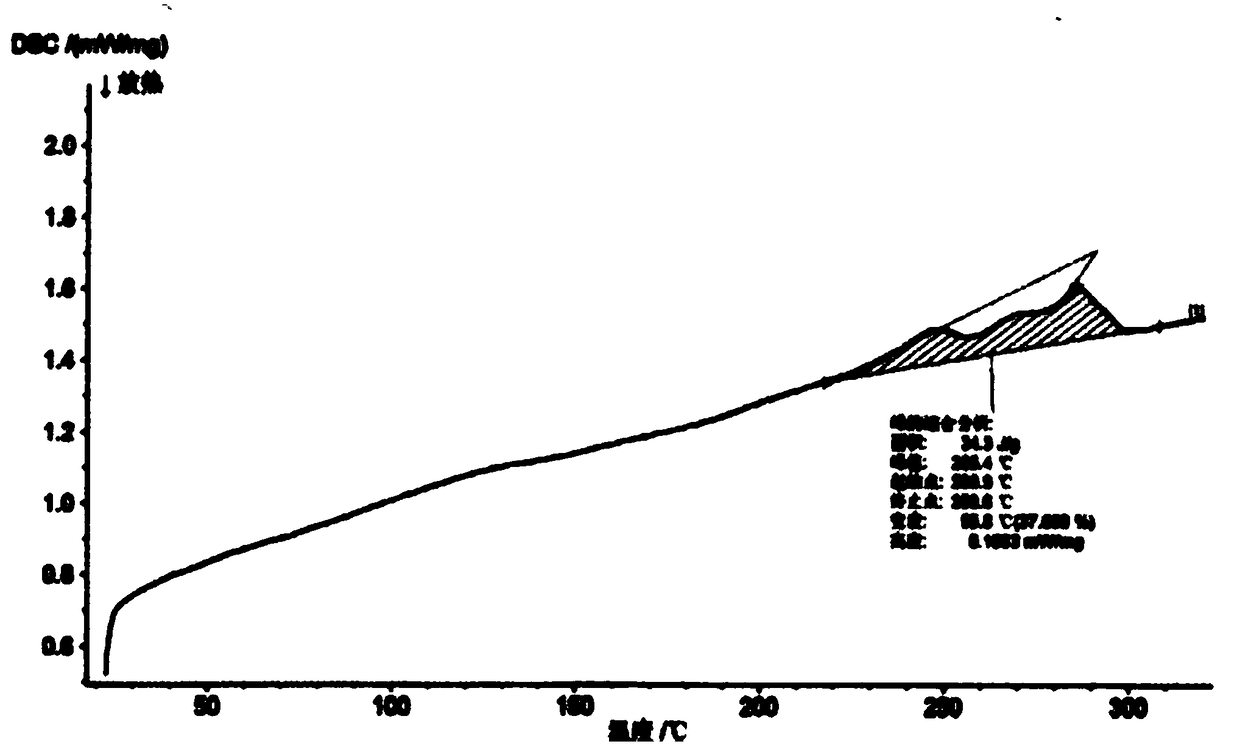

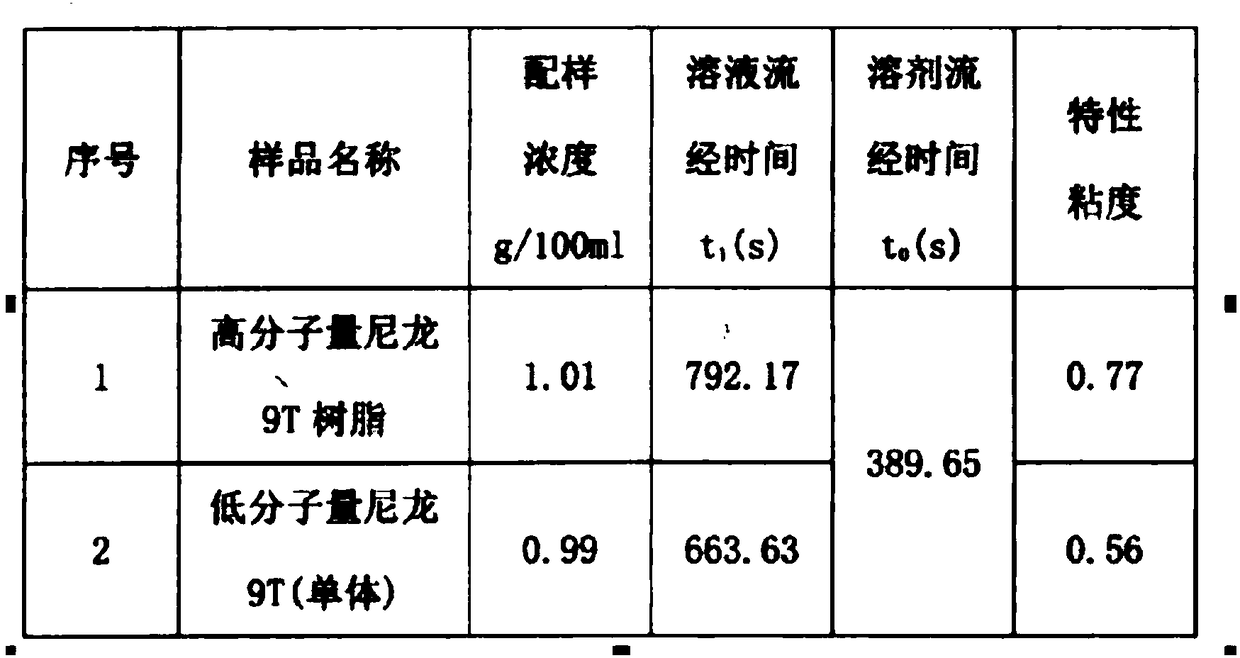

[0021] Described low-molecular-weight nylon 9T powder is that Japan's Kuraray company (Kuraray) obtains in the process of synthesizing nylon 9T resin by monomer terephthalic acid and monomer nonanediamine and is the by-product of 0.56dL / g intrinsic viscosity (its DSC test curve such as figure 1 , and its intrinsic viscosity is shown in Table 1).

[0022] The high-molecular-weight nylon 9T resin is formed by polycondensation of the following raw materials in parts by weight by combining liquid and solid phases: low-molecular-weight nylon 9T powder: 100 parts; water: 17 parts; catalyst (NaOH): 0.5 parts; Heat stabilizer: 0.15 parts;

[0023] The method includes the following steps:

[0024] 1) Add the raw materials into the polymerization kettle, adjust the pH value to 8.2, start heating the polymerization kettle to 1...

Embodiment 2

[0032] Reference Example 1, the difference is: raw material: low molecular weight nylon 9T powder: 100 parts; water: 60 parts; catalyst: 8 parts; thermal stabilizer: 3 parts; the catalyst is Na 2 SiO 3 ;

[0033] The method includes the following steps:

[0034] 1) Put the raw materials into the polymerization kettle, adjust the pH value to 7.1, vacuumize the pressure to -0.02MPa, control the reaction temperature at 250°C, and react for 3 hours to precipitate small molecule by-products and water;

[0035] 2) The raw materials are discharged from the polymerization kettle, transported by the mobile device to the twin-screw extruder for solid-phase polycondensation reaction, input inert gas carbon dioxide, the reaction temperature is 160-350°C, the vacuum pressure is -0.06MPa, and small molecule by-products are precipitated And moisture, the reaction is completed, the material is extruded from the twin-screw extruder, cooled, cut into pellets, and transported to the drying equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com