Flexible dielectric elastomer composite material based on nanometer liquid metal and preparation method thereof

A dielectric elastomer and liquid metal technology, applied in the field of dielectric materials, can solve the problem that the high dielectric constant and low dielectric loss of dielectric composite materials cannot be balanced, the flexibility and the rigidity of inorganic fillers do not match, and the nano-fillers cannot be used. and other problems to achieve the effect of increasing elastic modulus, preventing oxidation and reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: M / R=33:100

[0042] Nano liquid metal / elastomer flexible dielectric composites were prepared with Dow Corning's silicone rubber DC3481 as the elastomer matrix.

[0043] (1) 1g Galinstan liquid metal (liquid metal is purchased from alfa company, its composition is Ga:In:Sn=62wt%:22wt%:16wt%, density is 6.359g / cm 3 , melting point is 10.7℃), 0.02g of 3-mercaptopropyltriethoxysilane (KH580) was added to 70mL of absolute ethanol, ice-water bath, 2000W ultrasonic pulverization for 30min, the liquid metal was dispersed into a spherical shape with an average particle size of about 85nm Droplets to obtain a stable nano-liquid metal emulsion;

[0044] (2) Invert the obtained nano-liquid metal emulsion into a centrifuge tube, gently centrifuge at 3000r / min for 30min, remove the supernatant, and centrifuge and wash with absolute ethanol for 2-3 times. After the washing is completed, add 50mL of ethyl acetate to obtain a dispersed nano liquid metal emulsion;

[004...

Embodiment 2

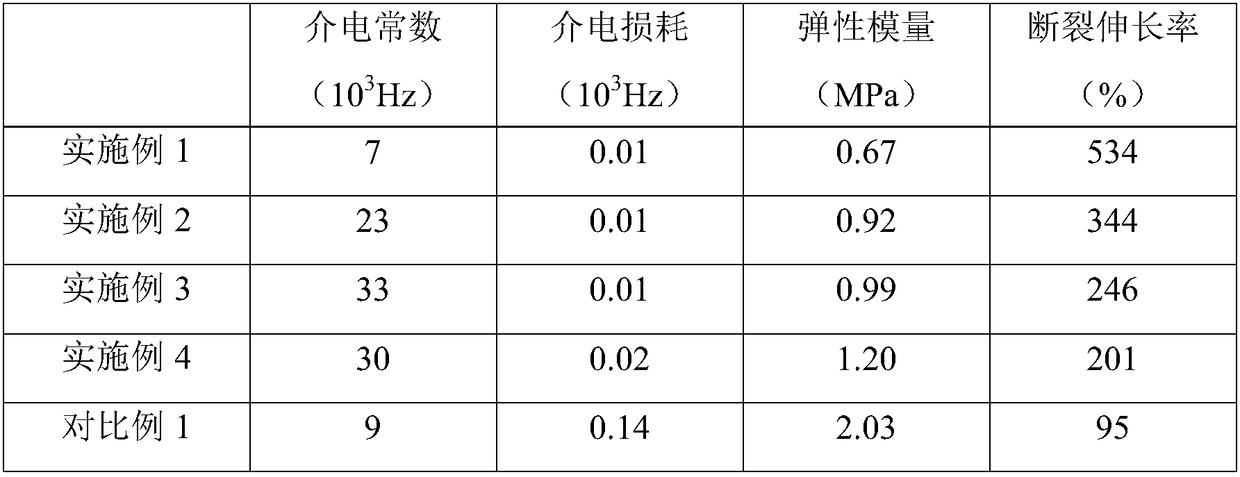

[0046] Embodiment 2: M / R=100:100

[0047] The preparation method is the same as in Example 1, except that the Galinstan liquid metal content in the step (1) is 3g, the KH580 content is 0.06g, and the dehydrated alcohol content is 100mL, and the ethyl acetate content in the step (2) is 70mL, and the liquid metal The average particle size is 99nm. The test method is the same as in Example 1, and the test results are shown in Table 1.

Embodiment 3

[0048] Embodiment 3: M / R=300:100

[0049] The preparation method is the same as in Example 1, except that the content of Galinstan liquid metal in step (1) is 9g, the content of KH580 is 0.09g, the content of absolute ethanol is 150mL, and the content of ethyl acetate in step (2) is 100mL. The average particle size of the liquid metal is 95nm, the test method is the same as in Example 1, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com