Preparation method of silicon carbon composite material

A silicon-carbon composite material and nano-silicon technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of easy cracking and poor bonding, and achieve increased bonding strength, improved bonding, and good bonding. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

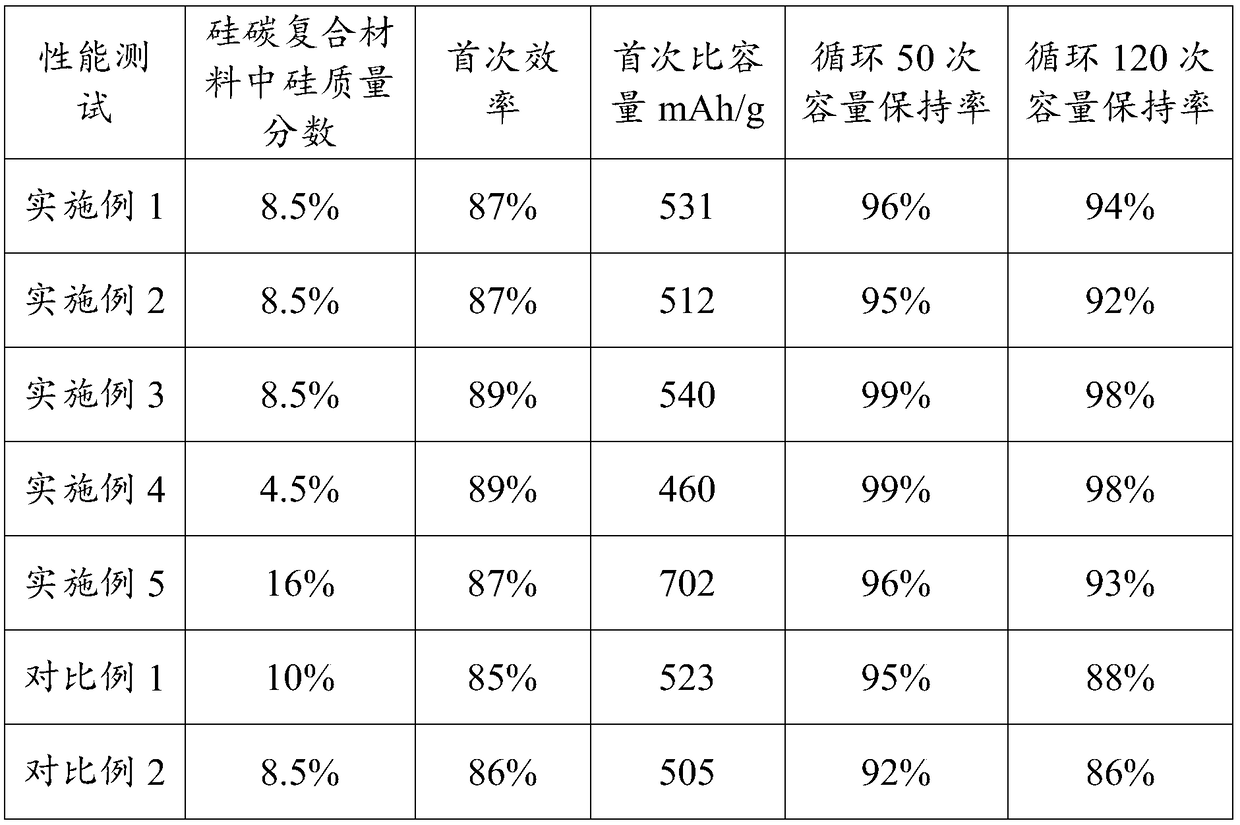

Examples

preparation example Construction

[0016] In one aspect, the present invention provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0017] S1) first add a silane coupling agent to the nano-silicon dispersion to react, then add graphene oxide to react, then add a dispersant, mix evenly to obtain a dispersion of graphene oxide-coated nano-silicon;

[0018] S2) In the state of shearing and stirring, spray the dispersion liquid of graphene oxide coated nano-silicon obtained in step S1) into the mixed powder of graphite and pitch I for shearing granulation to obtain precursor particles;

[0019] Wherein, the mass ratio of graphite, pitch I and nano silicon is 1:(0.03~0.1):(0.05~0.2);

[0020] S3) The precursor particles obtained in step S2) are dried and then sintered to reduce the graphene oxide in the precursor particles to graphene to obtain a silicon-carbon composite material.

[0021] In the preparation method of the silicon-carbon composite material provided b...

Embodiment 1

[0055] This embodiment is a method for preparing a silicon-carbon composite material, comprising the following steps:

[0056] S1) Add a silane coupling agent to the nano-silicon dispersion with a solid content of 30%, and stir and react at 50°C for 10h; add graphene oxide after the reaction is complete, and continue to stir and react at 50°C for 14h; the reaction is complete Finally, add a dispersant and stir evenly to obtain a dispersion of graphene oxide-coated nano-silicon;

[0057] S2) Graphite with a particle size of 0.5-5 μm and pitch I with a particle size of 0.5-3 μm are uniformly mixed according to a mass ratio of 1:0.08, and then added to a high-shear granulator; at the same time, the obtained The dispersion of graphene oxide-coated nano-silicon is sprayed into a high-shear granulator for shear granulation to obtain precursor particles;

[0058] Among them, the mass ratio of graphite and nano-silicon is 1:0.1; the shear speed is 2500r / min, the stirring speed is 700...

Embodiment 2

[0063] This embodiment is a method for preparing a silicon-carbon composite material, comprising the following steps:

[0064]S1) adding nano-silicon to the piranha lotion and reacting for 10 hours for pretreatment, wherein the mass ratio of the nano-silicon to the piranha lotion is 1:10; the pretreated nano-silicon has a solid content of 30 % dispersion liquid, add silane coupling agent, stir and react at 50°C for 10h; add graphene oxide after the reaction is completed, and continue to stir and react at 50°C for 14h; add dispersant after the reaction is completed, and stir evenly to prepare Obtain the dispersion liquid of graphene oxide coating nano-silicon;

[0065] S2) Graphite with a particle size of 0.5-5 μm and pitch I with a particle size of 0.5-3 μm are uniformly mixed according to a mass ratio of 1:0.08, and then added to a high-shear granulator; at the same time, the obtained The dispersion of graphene oxide-coated nano-silicon is sprayed into a high-shear granulato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com