Photocatalytic antibacterial hydrogel dressing and preparation method thereof

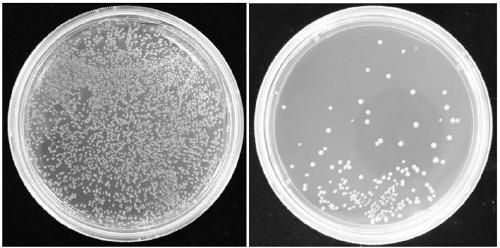

A hydrogel and photocatalytic technology, applied in medical science, bandages, etc., can solve the problems of bacterial infection, drug resistance during use, and no antibacterial performance, and achieve excellent photocatalytic antibacterial effect, fast Antibacterial, antibacterial effect long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

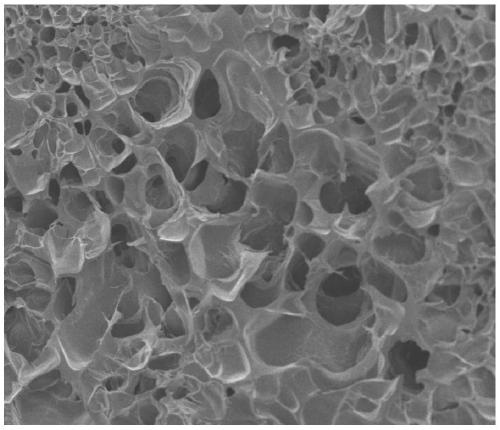

Embodiment 1

[0036] (1) Bismuth oxychloride thinning: add bismuth oxychloride (bismuth oxychloride accounts for 0.075wt% of the total amount (concentration of 0.025wt% sodium alginate solution + bismuth oxychloride)), and add it to the seaweed with a concentration of 0.025wt% Mix in the sodium solution, sonicate the mixed solution (power 80W, frequency 45Hz) for 12h, and take the supernatant liquid for later use;

[0037] (2) Mix the sodium alginate solution with a concentration of 1.5wt% and the supernatant in a mass ratio of 1:1, stir evenly, add acrylamide (the amount of acrylamide is 12.5% of the total mass of the mixed solution and acrylamide ), mix uniformly, add 0.06% crosslinking agent N,N-methylenebisacrylamide and 0.09% thermal initiator ammonium persulfate relative to the mass of acrylamide, and mix uniformly to obtain a prepolymerized liquid;

[0038] (3) Pour the pre-polymerization liquid into a mold with a length of 5 cm, a width of 5 cm and a thickness of 2 mm. Put the mold pou...

Embodiment 2

[0046] (1) Thinning bismuth oxychloride: add bismuth oxychloride (bismuth oxychloride accounts for 0.1wt% of the total amount (concentration of 0.05wt% sodium alginate solution + bismuth oxychloride)), and add it to 0.05wt% Mix in the sodium alginate solution, sonicate the mixed solution (power is 100W, frequency is 45Hz) for 10h, and take the supernatant for use;

[0047] (2) Mix the sodium alginate solution with a concentration of 1.75% by weight and the supernatant at a mass ratio of 1:1. After stirring, add acrylamide (the amount of acrylamide is 15% of the total mass of the mixed solution and acrylamide ), mix uniformly, add 0.06% crosslinking agent N,N-methylenebisacrylamide and 0.09% thermal initiator ammonium persulfate relative to the mass of acrylamide, and mix uniformly to obtain a prepolymerized liquid;

[0048] (3) Pour the pre-polymerization liquid into a mold with a length of 5 cm, a width of 5 cm and a thickness of 2 mm. Put the mold poured into the pre-polymerizati...

Embodiment 3

[0054] (1) Thinning bismuth oxychloride: add bismuth oxychloride (bismuth oxychloride accounts for 0.125wt% of the total amount (concentration of 0.1wt% sodium alginate solution + bismuth oxychloride)), and add it to the 0.1wt% Mix in the sodium alginate solution, sonicate the mixed solution (power 150W, frequency 45Hz) for 8h, and take the supernatant for use;

[0055] (2) Mix the sodium alginate solution with a concentration of 2wt% and the supernatant at a mass ratio of 1:1. After stirring, add acrylamide (the amount of acrylamide is 16% of the total mass of the mixed solution and acrylamide) , Mix uniformly, add 0.08% crosslinking agent N,N-methylenebisacrylamide and 0.1% thermal initiator ammonium persulfate relative to the mass of acrylamide, and mix uniformly to obtain prepolymerization liquid;

[0056] (3) Pour the pre-polymerization liquid into a mold with a length of 5 cm, a width of 5 cm and a thickness of 2 mm. Put the mold poured into the pre-polymerization solution in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com