Method for producing cyanoethylalkoxysilane by atmospheric distillation reaction

A technology of cyanoethylalkoxysilane and cyanoethyltrichlorosilane is applied in the field of producing cyanoethylalkoxysilane, and can solve the problems of inability to continuously produce for a long time, excessive use of entrainers, low production capacity and the like, Achieve the effect of large production capacity, reduced energy consumption and low acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

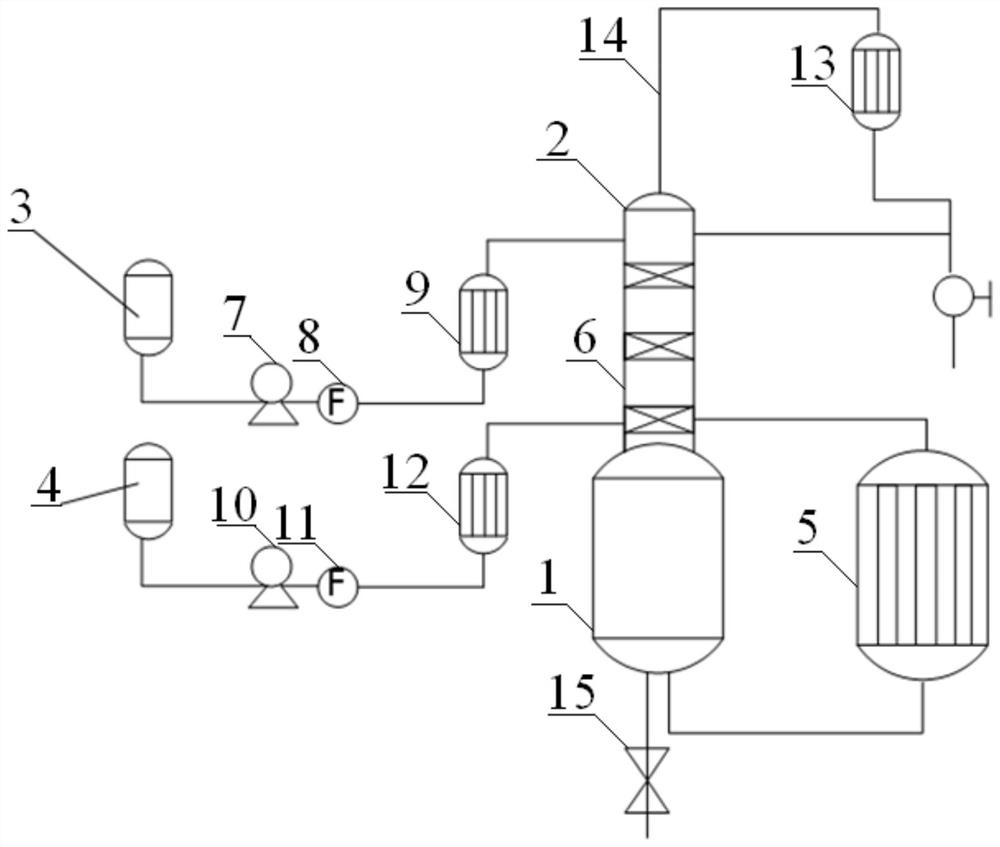

[0017] Specific embodiment one: the device for producing cyanoethyl alkoxysilane by atmospheric distillation reaction in this embodiment, the device includes a tower kettle 1, a packed tower 2, a first storage tank 3, a second storage tank 4 and a first replacement tank Heater 5, described tower reactor 1 and packed tower 2 form tower reactor 6, the first heat exchanger 5 links to each other with tower reactor 1 and packed tower 2 respectively, and first storage tank 3 and second storage tank 4 are respectively connected with The packed towers 2 are connected, the first pump 7, the first flow meter 8 and the second heat exchanger 9 are arranged between the first storage tank 3 and the packed tower 2, and the second storage tank 4 and the packed tower 2 are arranged Two pumps 10, a second flowmeter 11 and a third heat exchanger 12, the top of the packed tower 2 is provided with a tail gas pipe 14, the tail gas pipe 14 is provided with a fourth heat exchanger 13, the tail gas pip...

specific Embodiment approach 2

[0018] Specific embodiment two: the method for the production of cyanoethylalkoxysilane by atmospheric distillation reaction in this embodiment is carried out according to the following steps:

[0019] 1. First, lay the bottom of cyanoethyl alkoxysilane on the bottom of tower reactor 6 and tank 1, and pass the entrainer into tower reactor 6 until the temperature of tower tank 1 is 220°C-240°C, of which cyanoethyl alkoxysilane The mass ratio of base alkoxysilane to entrainer is 10-20:1;

[0020] Two, from the bottom of the tower reactor 6 to the tower reactor 1 of the tower reactor 6, the monohydric aliphatic alcohol is continuously passed into the tower reactor 6 at a rate of 128g / h-256g / h, from the top of the tower reactor 6 to the tower reactor 6 Continuously feed cyanoethyltrichlorosilane at a rate of 175g / h-350g / h, and react under the condition that the temperature in the atmospheric column tank 1 is 100-120°C, and during the reaction, use 5g / h- Supplement entrainer at ...

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the entrainer described in step 1 and step 2 is toluene, acetonitrile, n-hexane or cyclohexane. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com