Method for selectively synthesizing hexafluoropropylene oxide oligomer

A hexafluoropropylene oxide, selective technology, applied in the field of selective synthesis of hexafluoropropylene oxide oligomers, can solve the problems of low reaction temperature, low trimer selectivity, limited use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Weigh 2.33g (0.04mol) of anhydrous potassium fluoride, 17.8g of tetraethylene glycol dimethyl ether and 7.27g (0.04mol) of P, P-diisopropoxyphosphonamide, and add them to a 500mL 316L In a reaction kettle, stir and cool to 0°C under a sealed environment. Open the feed valve to feed 200g (1.2mol) of hexafluoropropylene oxide gas into the reactor, and stabilize the reaction temperature at 40±5°C by regulating the temperature of the cooling liquid and controlling the intake rate; To room temperature, discharge, and liquid separation to obtain 192.85 g of crude product of hexafluoropropylene dimer in the lower layer of colorless transparent oil phase, the content of dimer is 86.54%, and the content of trimer and tetramer is 13.46%.

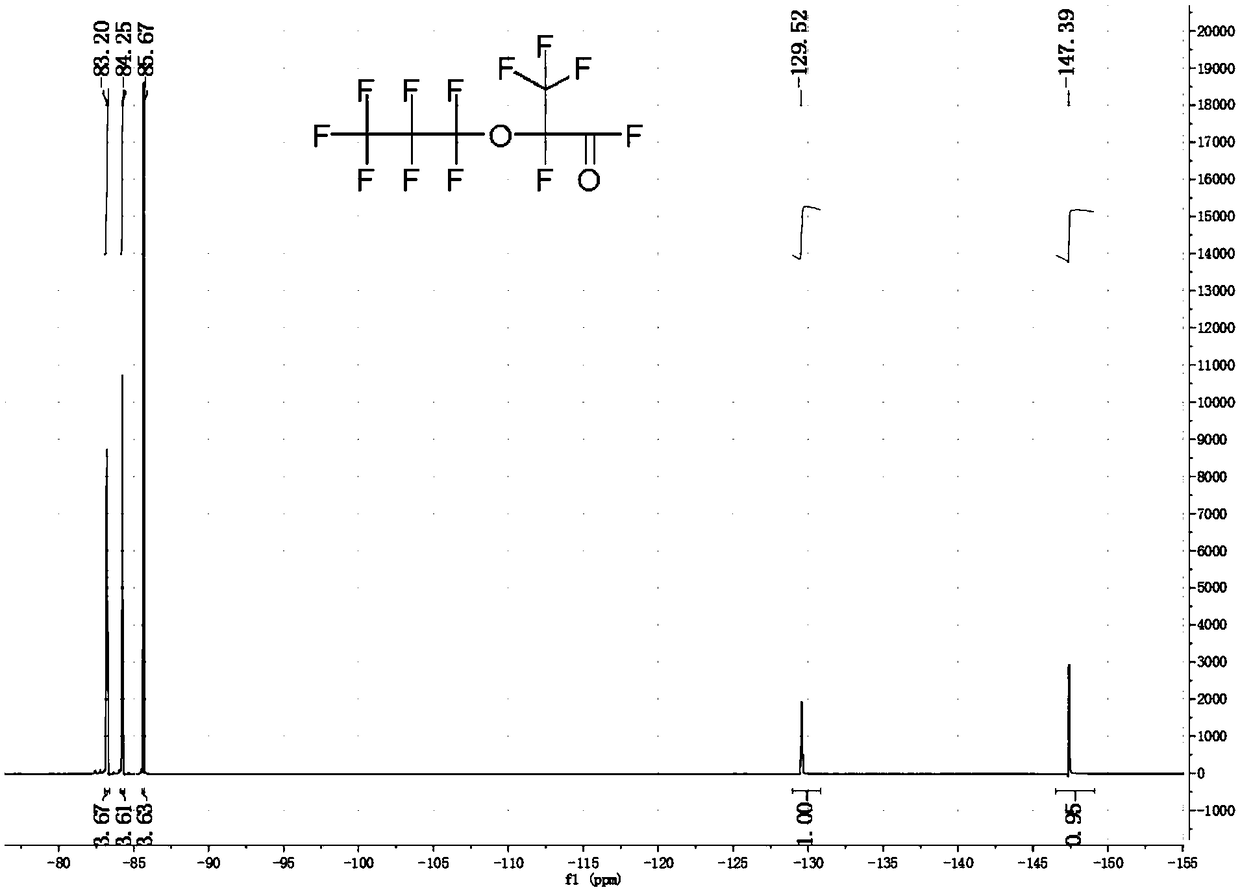

[0048] The product in this example is carried out structural identification (19F-NMR), the result is as follows figure 1 as shown, figure 1 It is the fluorine spectrum of the product in Example 1 of the present invention. Depend on figure 1...

Embodiment 2

[0050] Take by weighing 11.65g (0.2mol) anhydrous potassium fluoride, 89.00g tetraethylene glycol dimethyl ether and 39.96g (0.2mol) P-isopropoxy-P-phenylphosphonamide, add to In a 2000mL 316L reaction kettle, stir in a sealed environment and cool to -10°C. Open the feed valve to feed 1000g (6.0mol) of hexafluoropropylene oxide gas into the reactor, and stabilize the reaction temperature at 50±5°C by regulating the temperature of the cooling liquid and controlling the intake velocity; to room temperature, discharge, and liquid separation to obtain 993.35 g of crude product of hexafluoropropylene dimer in the lower colorless transparent oil phase, the content of dimer is 85.94%, and the content of trimer and tetramer is 14.06%.

Embodiment 3

[0052] Weigh 2.07g (0.02mol) of anhydrous zinc fluoride, 17.8g of tetraethylene glycol dimethyl ether and 7.27g (0.04mol) of P, P-diisopropoxyphosphonamide, and add it to a 500mL 316L In a reaction kettle, stir and cool to 0°C under a sealed environment. Open the feed valve to feed 200g (1.2mol) of hexafluoropropylene oxide gas into the reactor, and stabilize the reaction temperature at 40±5°C by regulating the temperature of the cooling liquid and controlling the intake rate; To room temperature, discharge, liquid separation to obtain 195.09 g of crude hexafluoropropylene trimer in the lower layer of colorless transparent oil phase, the content of trimer is 84.59%, and the content of dimer and tetramer is 15.41%.

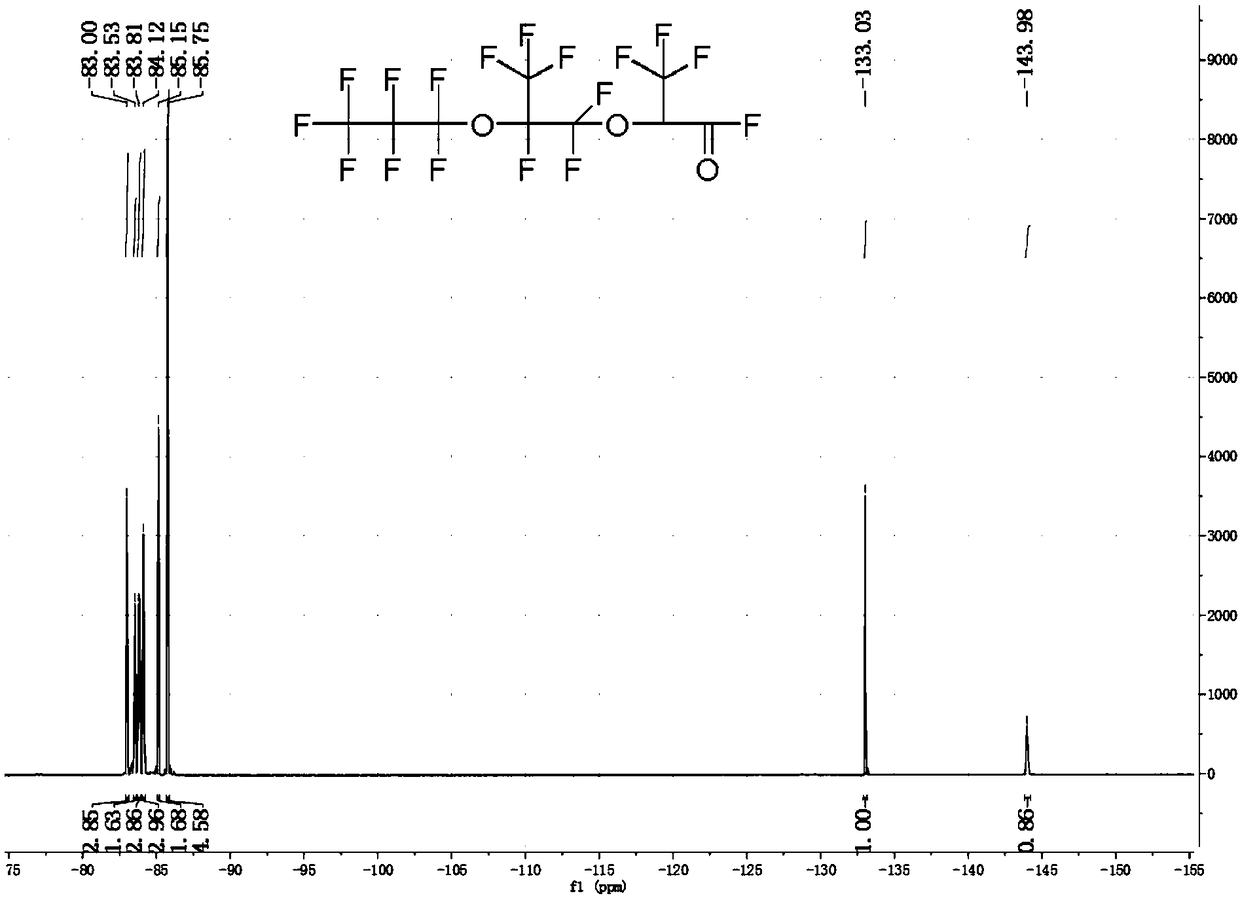

[0053] The product in this example is carried out structural identification (19F-NMR), the result is as follows figure 2 as shown, figure 1 It is the fluorine spectrum of the product in Example 3 of the present invention. Depend on figure 2 It can be seen tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com