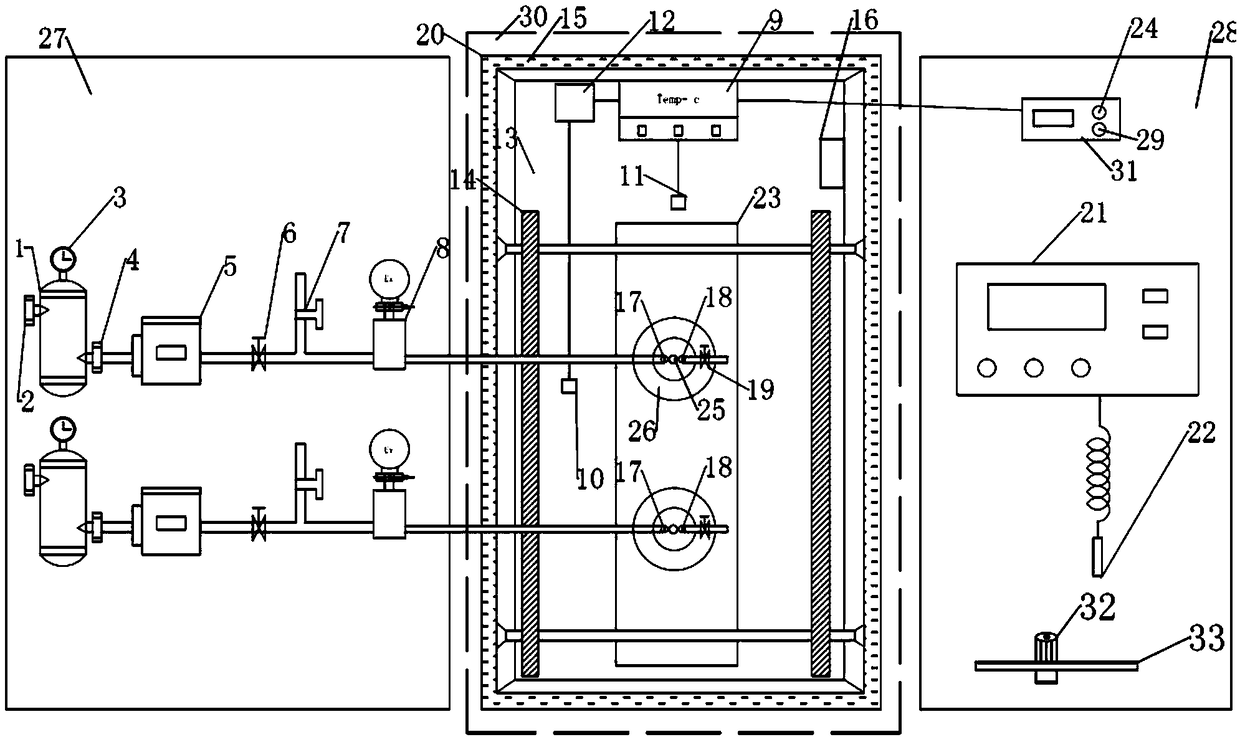

Magnetic field-controllable marsh gas anaerobic fermentation device and fermentation method

A technology of anaerobic fermentation and magnetic field regulation, which is applied in the direction of stress-stimulated microbial growth, fermentation, and special-purpose bioreactors/fermenters. Efficiency and gas production rate, energy saving effect improvement, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

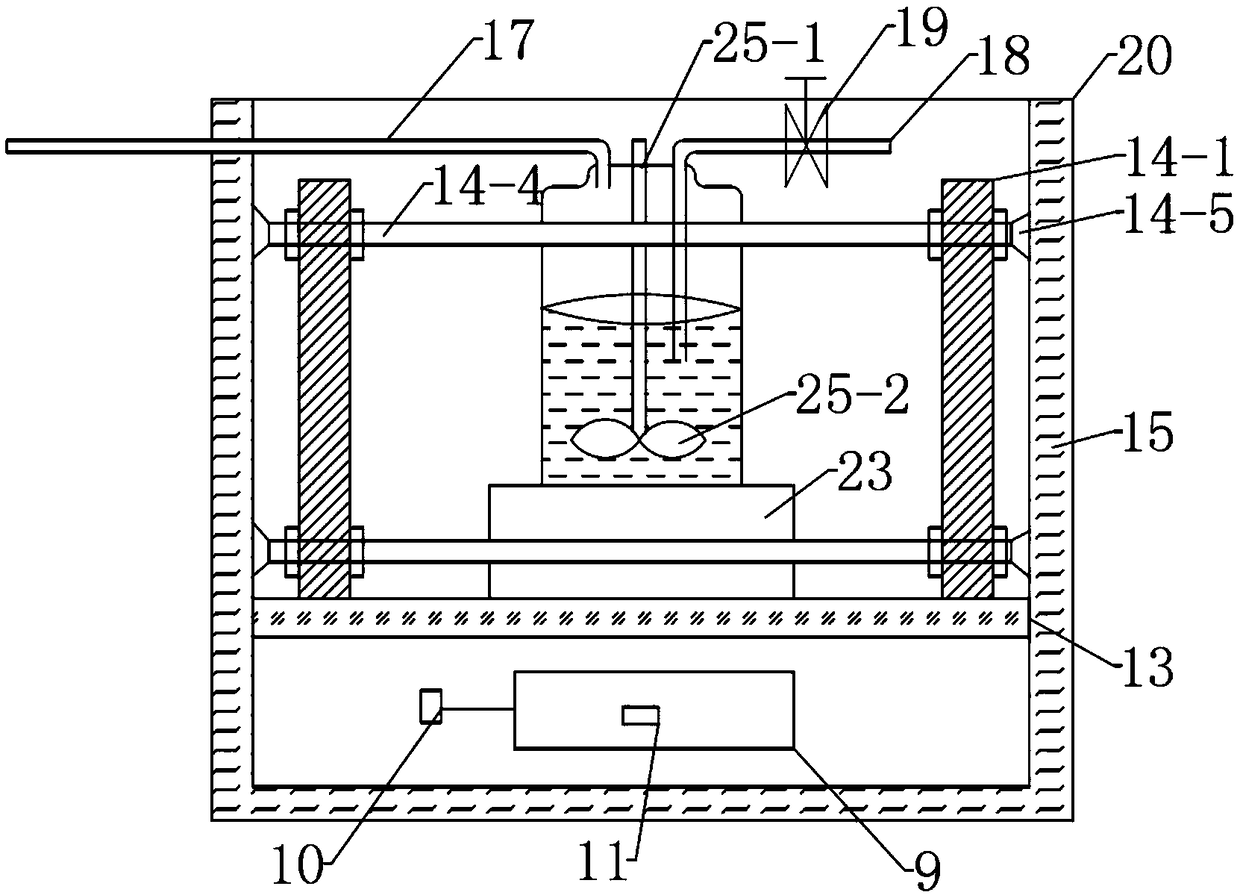

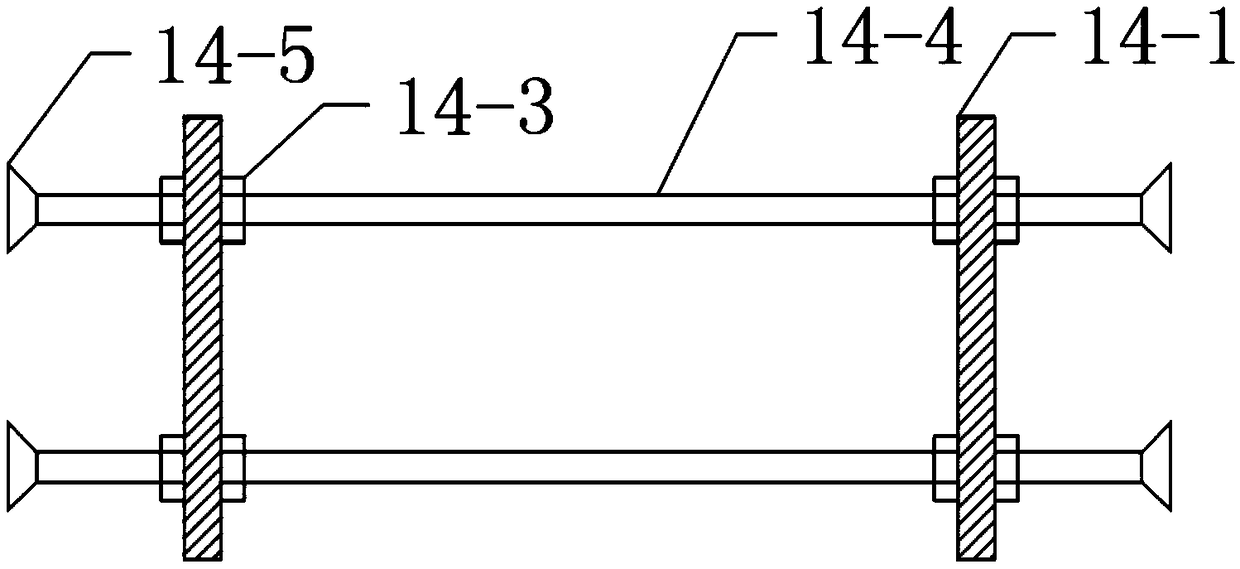

Method used

Image

Examples

Embodiment 1

[0060] 1) Control the fermentation temperature: control the temperature in the constant temperature water bath heating device, so that the fermentation temperature of the fermentation reactor is controlled at 35°C;

[0061] 2) Adjust the magnetic field: adjust the equipment so that the magnetic field strength is 6mT;

[0062] 3) Using a magnetic field environment for biogas fermentation:

[0063] With 180 parts by mass of cow dung as the fermentation raw material, add 320 parts of anaerobic sludge from the urban sewage treatment plant, pump it into the feeding pipe, and then be pumped into the fermentation reactor through the air inlet feeding pipe; The gas feed pipe is connected to the nitrogen tank, and ventilated for 3 minutes to remove oxygen; it is sealed through the valve at the end of the gas collecting pipe;

[0064] 4) Fully stir the fermentation raw materials and anaerobic sludge added to the reactor, control the total solid content of anaerobic fermentation to 10%,...

Embodiment 2

[0067] 1) Control the fermentation temperature: control the temperature in the constant temperature water bath heating device, so that the fermentation temperature of the fermentation reactor is controlled at 30°C;

[0068] 2) Adjust the magnetic field: adjust the equipment so that the magnetic field strength is 15mT;

[0069] 3) Using a magnetic field environment for biogas fermentation:

[0070] 180 parts by mass of pig manure are used as fermentation raw materials, and then 320 parts of anaerobic sludge from urban sewage treatment plants are added, pumped into the feeding pipe, and then pumped into the fermentation reactor through the air inlet feeding pipe; The gas feed pipe is connected to the nitrogen tank, and ventilated for 5 minutes to remove oxygen; it is sealed through the valve at the end of the gas collecting pipe;

[0071] 4) Fully stir the fermentation feed liquid added to the reactor, control the total solid content of the anaerobic fermentation to 10%, and fe...

Embodiment 3

[0074] 1) Control the fermentation temperature: control the temperature in the constant temperature water bath heating device, so that the fermentation temperature of the fermentation reactor is controlled at 40°C;

[0075] 2) Adjust the magnetic field: adjust the equipment so that the magnetic field strength is 27mT;

[0076] 3) Using a magnetic field environment for biogas fermentation:

[0077] 180 parts by mass of chicken manure are used as fermentation raw materials, and then 320 parts of anaerobic sludge from urban sewage treatment plants are added, pumped into the feeding pipe, and then injected into the fermentation reactor through the air inlet feeding pipe; The gas feed pipe is connected to the nitrogen tank, ventilated for 4 minutes to remove oxygen; it is sealed through the valve at the end of the gas collecting pipe;

[0078] 4) Fully stir the fermentation raw materials and anaerobic sludge added to the reactor, control the total solid content of the anaerobic fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com