Health far infrared anion polyester fiber

A far-infrared negative ion and polyester fiber technology, which is applied in the field of health care far-infrared negative ion polyester fiber and its preparation, and far-infrared functional masterbatch. It can solve the problems of poor durability and water resistance, limited active ingredient content, and poor resonance band matching. , to achieve the effect of improving the far-infrared efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

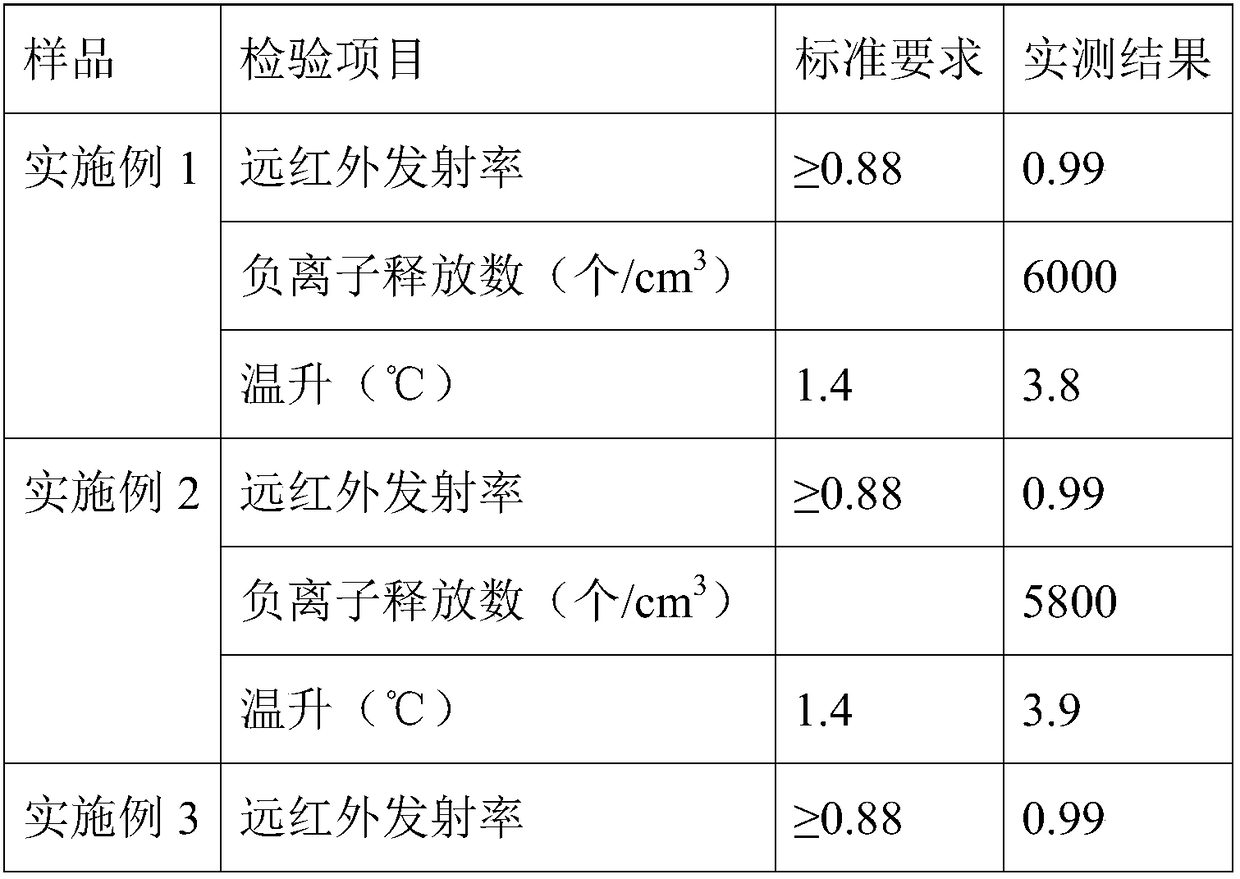

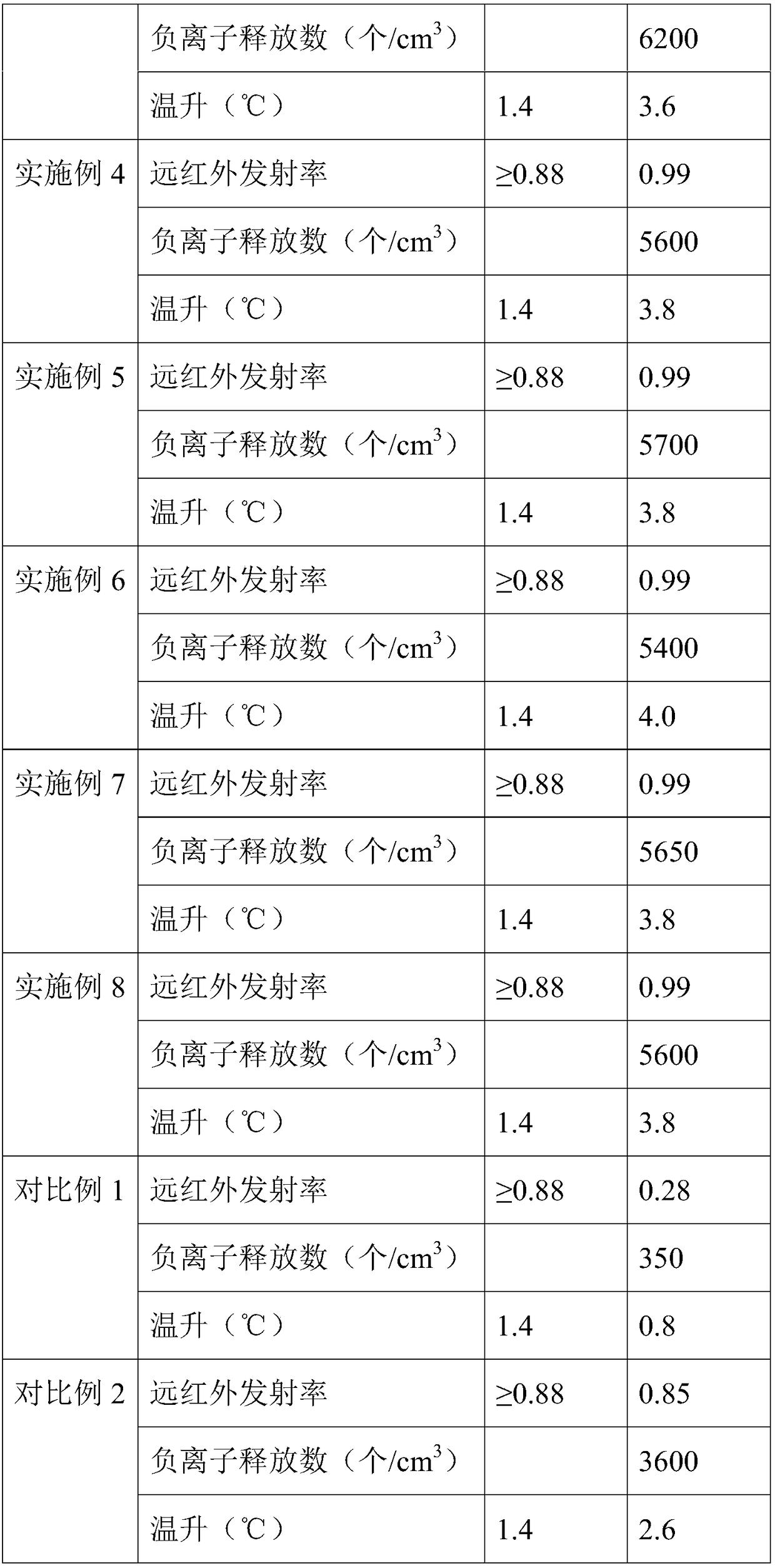

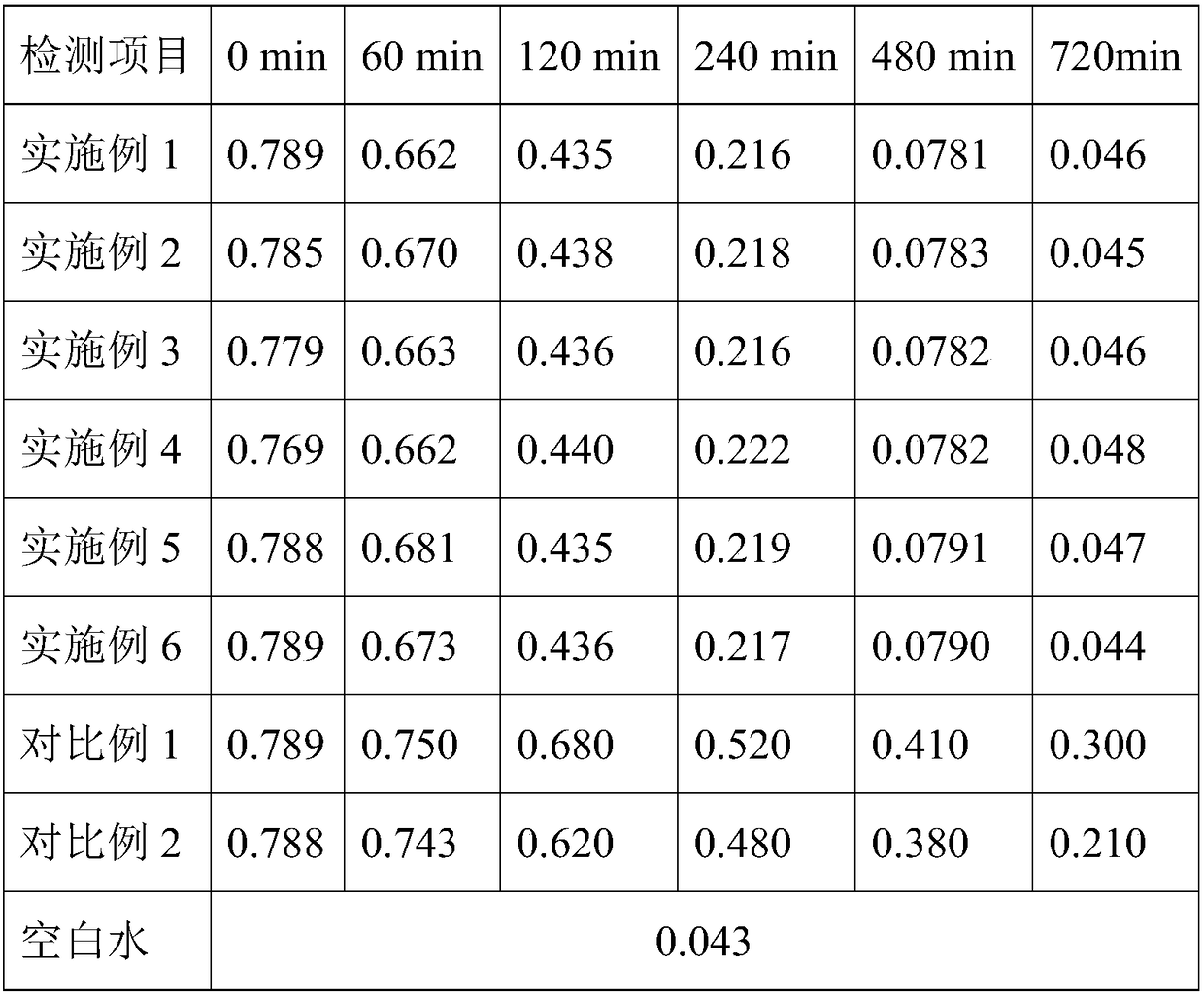

Examples

preparation example Construction

[0050] Correspondingly, the present invention also provides a method for preparing the above-mentioned far-infrared functional masterbatch according to an embodiment, including the following steps S1-S2.

[0051] Step S1: In parts by weight, 5-10 parts of tourmaline, 10-15 parts of vermiculite, 5-10 parts of medical stone, 15-20 parts of kaolin, 8-15 parts of alumina, 0.5-1 parts of oxide The zirconium and 0.1-0.5 parts of yttrium oxide are uniformly mixed, calcined at 500-700° C. for 1-4 hours, and ground to obtain a far-infrared ceramic material.

[0052] In one of the embodiments, in parts by weight, in the far-infrared ceramic material, tourmaline is 5-8 parts, vermiculite is 10-13 parts, medical stone is 5-8 parts, and kaolin is 15-17 parts. 10-15 parts for alumina, 0.5-0.8 parts for zirconia, and 0.3-0.5 parts for yttrium oxide. The far-infrared ceramic material within the proportioning range, the anion release amount and the far-infrared emissivity of the polyester fib...

Embodiment 1

[0083] (1) Synthesis of PET fiber: dimethyl terephthalate and ethylene glycol ingredients with a molar ratio of 1:2.2 are made by high-temperature polycondensation under the action of a catalyst.

[0084] (2) Synthesis of PETG fiber: dimethyl terephthalate, ethylene glycol, and 1,4-cyclohexanedimethanol with a molar ratio of 1:1.8:0.3 are prepared by high-temperature polycondensation under the action of a catalyst .

[0085] (3) Preparation of far-infrared ceramic materials: Mix 8 parts of tourmaline, 10 parts of vermiculite, 8 parts of medical stone, 15 parts of kaolin, and 10 parts of alumina, and then add 0.6 parts of zirconia and 0.3 parts of yttrium oxide to make into a mixed powder, calcined in a muffle furnace at 550°C for 2 hours, cooled and ground to a particle size of 300-500nm, and then added a powder surface treatment agent for further grinding to produce a far-infrared ceramic material.

[0086] (4) Preparation of far-infrared functional masterbatch: mix 100 part...

Embodiment 2

[0090] Embodiment 2 is basically the same as Example 1, except that the formula of polyester fiber in step (6) is 80 parts of PET fiber, 20 parts of PETG fiber, 4 parts of functional masterbatch and 0.03 part of silver-loaded titanium dioxide / graphene Composite particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com