Preparation method and application of modified biochar composite modified with magnetic hydrotalcite

A technology of magnetic hydrotalcite and composite materials, which is applied in the direction of water pollutants, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of low separation efficiency, achieve a large specific surface area, enhance the ability to adsorb ammonia nitrogen, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

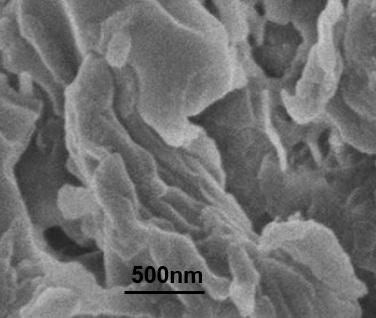

Image

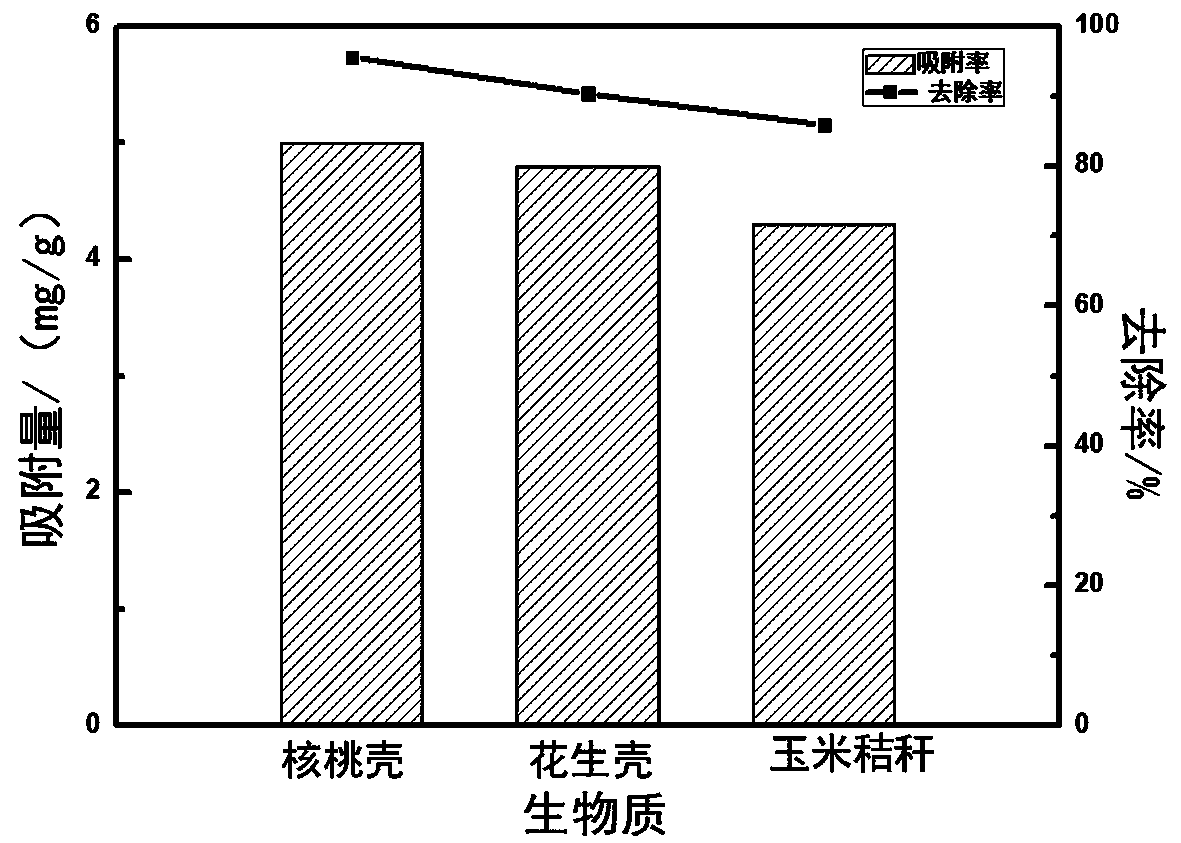

Examples

Embodiment 1

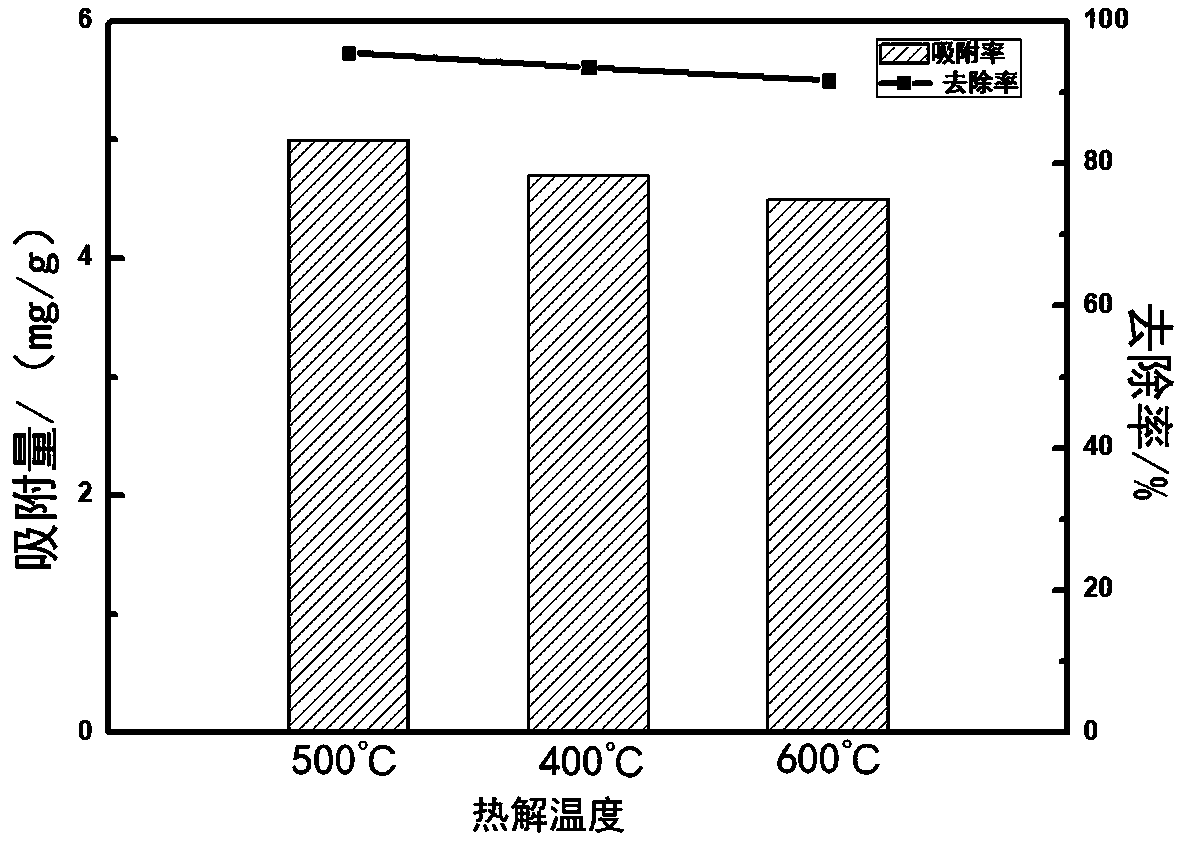

[0040] A preparation method of a modified biochar composite material modified by magnetic hydrotalcite, comprising the steps of:

[0041]S1. Clean the biomass raw material with deionized water, then put it into a biochar furnace, and perform a pre-pyrolysis reaction at 500°C to prepare biochar, and grind it through an 80-mesh sieve for later use;

[0042] S2, soak the biochar prepared in the above steps in 1mol / L NaOH solution, take it out after 24h, then wash with deionized water until neutral, and dry;

[0043] S3, pyrolyzing the product obtained in the above steps again, setting the temperature at 500°C, washing with deionized water until neutral, and drying;

[0044] S4, the product that above-mentioned step is made soaks in 1mol / L MgCl 2 Mg in solution for 24h 2+ modified, then taken out, washed with deionized water until neutral, and dried to obtain modified biochar;

[0045] S5, take Fe(NO 3 ) 2 ·6H 2 O, Fe(NO3) 3 9H 2 O and NaOH aqueous solution preparation sol...

Embodiment 2

[0052] A preparation method of a modified biochar composite material modified by magnetic hydrotalcite, comprising the steps of:

[0053] S1. Wash the raw material of walnut shell biomass with deionized water, then put it into a biochar furnace, perform a pre-pyrolysis reaction to prepare biochar, and grind it through an 80-mesh sieve for later use;

[0054] S2, soak the biochar prepared in the above steps in 1mol / L NaOH solution, take it out after 24h, then wash with deionized water until neutral, and dry;

[0055] S3, pyrolyzing the product obtained in the above steps again, then washing with deionized water to neutrality, and drying;

[0056] S4, the product that above-mentioned step is made soaks in 1mol / L MgCl 2 Mg in solution for 24h 2+ modified, then taken out, washed with deionized water until neutral, and dried to obtain modified biochar;

[0057] S5, take Fe(NO 3 ) 2 ·6H 2 O, Fe(NO3) 3 9H 2 O and NaOH aqueous solution preparation solution A; take Ca(NO 3 ) ...

Embodiment 3

[0066] A preparation method of a modified biochar composite material modified by magnetic hydrotalcite, comprising the steps of:

[0067] S1. Wash the raw material of walnut shell biomass with deionized water, then put it into a biochar furnace, perform a pre-pyrolysis reaction at 500°C to prepare biochar, and grind it through an 80-mesh sieve for later use;

[0068] S2, soak the biochar prepared in the above steps in 1mol / L NaOH solution, take it out after 24h, then wash with deionized water until neutral, and dry;

[0069] S3, pyrolyzing the product obtained in the above steps again, setting the temperature at 500°C, washing with deionized water until neutral, and drying;

[0070] S4, the product that above-mentioned step is made soaks in 1mol / L MgCl 2 Mg in solution for 24h 2+ modified, then taken out, washed with deionized water until neutral, and dried to obtain modified biochar;

[0071] S5, take Fe(NO 3 ) 2 ·6H 2 O, Fe(NO3) 3 9H 2 O and NaOH aqueous solution pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com