Preparation method of magnesium-nitrogen co-doped biomass activated carbon with high specific surface area

A high specific surface area, co-doping technology, used in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problem of high cost, and achieve the effect of improving adsorption capacity, easy processing, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

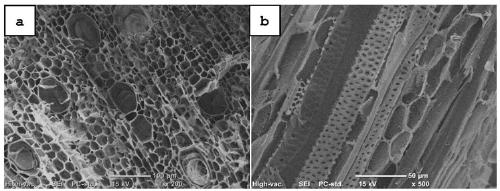

[0028] A kind of preparation method of magnesium nitrogen co-doped high specific surface area biomass activated carbon: specifically as follows: hemp core (scanning electron microscope picture sees figure 1 ) after cleaning with distilled water, dry at 100°C, and cut into small sections of about 3 cm; impregnate the small pieces of hemp core in the water mixed solution of zinc chloride and magnesium chloride, the concentration of the mixed aqueous solution is 50%, and the chlorine in the mixed aqueous solution The mass ratio of zinc chloride to magnesium chloride is 4:1, and the mass ratio of zinc chloride to impregnated hemp core is 4:1. After impregnating under reduced pressure in a vacuum oven for 24 hours, it was filtered, and then dried at 80°C for 24 hours. The dried hemp core was placed in a tube furnace, and the temperature was raised to 600°C at a rate of 5°C / min under a nitrogen atmosphere, kept at 600°C for 2 hours, and then cooled to room temperature under a nitrog...

Embodiment 2

[0030] A preparation method of high specific surface area biomass activated carbon co-doped with magnesium and nitrogen: the details are as follows: the hemp core is washed with distilled water, dried at 100°C, and cut into small sections of 3 cm. The hemp core pieces are dipped in a mixed solution of zinc chloride and magnesium chloride. The concentration of the mixed solution is 50%, the mass ratio of zinc chloride and magnesium chloride in the mixed solution is 4:1, and the mass ratio of zinc chloride and impregnated hemp core is 2:1. After impregnating under reduced pressure in a vacuum oven for 24 hours, it was filtered, and then dried at 80°C for 24 hours. The dried hemp cores were placed in a tube furnace, and the temperature was raised to 800°C at a rate of 5°C / min under a nitrogen atmosphere, kept at 800°C for 2 hours, and then cooled to room temperature under a nitrogen atmosphere. Soak the obtained carbonized product with dilute hydrochloric acid solution (concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com