Multi-component small-amount high-strength plasticity magnesium alloy and large-rolling-reduction short-process preparation method thereof

A large reduction, magnesium alloy technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of complicated process flow of deformed magnesium alloy, few types of added alloy elements, and difficult preparation of magnesium alloy sheet. , to achieve the effect of improving the complex rolling process, small rolling cracks, and promoting non-base surface slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

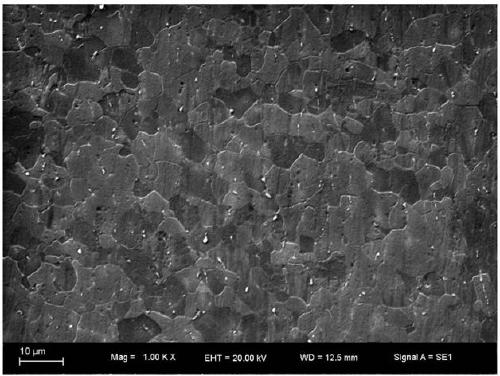

Image

Examples

Embodiment 1

[0036] Take Mg-1Zn-1Sn-0.2Ca-0.2Y alloy as an example, according to the mass percentage of the alloy for batching:

[0037] (1) Pass the shielding gas into the melting furnace, the shielding gas can be argon or SF 6 And CO 2 Put the pure magnesium ingot into the crucible and heat and melt it at 700℃;

[0038] (2) After the magnesium ingot is melted, the temperature is lowered to 680°C, and slagging removes impurities and oxide layers on the surface of the melt to obtain a pure magnesium melt;

[0039] (3) After degassing and refining the above-mentioned pure magnesium melt, pure zinc and pure tin are added to the pure magnesium melt to obtain a magnesium alloy melt;

[0040] (4) After holding the above-mentioned magnesium alloy melt at 700°C for 10-20 minutes, add magnesium-calcium and magnesium-yttrium master alloys to the magnesium alloy solution. After it is completely melted, fully stir the melt and blow from the bottom of the melt. After refining with argon gas, remove surface im...

Embodiment 2

[0049] Take Mg-0.8Zn-1.5Sn-0.3Ca-0.08Y alloy as an example, and do the batching according to the mass percentage of the alloy:

[0050] (1) Pass the shielding gas into the melting furnace, the shielding gas can be argon or SF 6 And CO 2 Put the pure magnesium ingot into the crucible and heat and melt it at 700℃;

[0051] (2) After the magnesium ingot is melted, the temperature is lowered to 680°C, and the impurities and oxide layer on the surface of the melt are removed by slagging to obtain a pure magnesium melt;

[0052] (3) After degassing and refining the above-mentioned pure magnesium melt, pure zinc and pure tin are added to the pure magnesium melt to obtain a magnesium alloy melt;

[0053] (4) After holding the above magnesium alloy melt at 700°C for 10-20 minutes, add magnesium-calcium and magnesium-yttrium master alloys to the magnesium alloy solution. After it is completely melted, stir the melt sufficiently and blow from the bottom of the melt. After refining with argon, th...

Embodiment 3

[0061] Take the Mg-1.5Zn-0.8Sn-0.08Ca-0.3Y alloy as an example, according to the mass percentage of the alloy for batching:

[0062] (1) Pass the shielding gas into the melting furnace, the shielding gas can be argon or SF 6 And CO 2 Put the pure magnesium ingot into the crucible and heat and melt it at 700℃;

[0063] (2) After the magnesium ingot is melted, the temperature is lowered to 680°C, and the impurities and oxide layer on the surface of the melt are removed by slagging to obtain a pure magnesium melt;

[0064] (3) After degassing and refining the above-mentioned pure magnesium melt, pure zinc and pure tin are added to the pure magnesium melt to obtain a magnesium alloy melt;

[0065] (4) After holding the above magnesium alloy melt at 700°C for 10-20 minutes, add magnesium-calcium and magnesium-yttrium intermediate alloys to the magnesium alloy solution, and also add magnesium-zirconium, magnesium-gadolinium, and magnesium-manganese intermediates One or more of the alloys, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com