A small amount of multi-component high-strength plastic magnesium alloy and its preparation method with a large reduction and a short process

A magnesium alloy, short-process technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of complicated process flow of deformed magnesium alloy, difficulty in preparing magnesium alloy plate, and few types of added alloy elements, etc., to achieve Improve the complex rolling process, promote non-base surface slippage, and reduce rolling cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

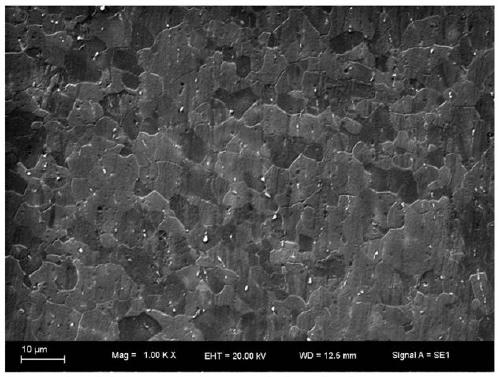

Image

Examples

Embodiment 1

[0036] Taking the Mg-1Zn-1Sn-0.2Ca-0.2Y alloy as an example, the ingredients are prepared according to the mass percentage of the alloy:

[0037] (1) Pass the protective gas into the melting furnace, the protective gas can be argon or SF 6 and CO 2 The mixed gas, put the pure magnesium ingot into the crucible and heat and melt at the temperature of 700 ℃;

[0038] (2) After the magnesium ingot is melted, the temperature is lowered to 680°C, and the impurities and oxide layer on the surface of the melt are removed by slag removal to obtain a pure magnesium melt;

[0039] (3) After the above-mentioned pure magnesium melt is degassed and refined, pure zinc and pure tin are added to the pure magnesium melt to obtain a magnesium alloy melt;

[0040] (4) After the above-mentioned magnesium alloy melt is kept at 700°C for 10-20 minutes, the magnesium-calcium and magnesium-yttrium intermediate alloys are added to the magnesium alloy melt. After it is completely melted, the melt is f...

Embodiment 2

[0049] Taking the Mg-0.8Zn-1.5Sn-0.3Ca-0.08Y alloy as an example, the ingredients are prepared according to the mass percentage of the alloy:

[0050] (1) Pass the protective gas into the melting furnace, the protective gas can be argon or SF 6 and CO 2 The mixed gas, put the pure magnesium ingot into the crucible and heat and melt at the temperature of 700 ℃;

[0051] (2) After the magnesium ingot is melted, the temperature is lowered to 680°C, and the impurities and oxide layer on the surface of the melt are removed by slag removal to obtain a pure magnesium melt;

[0052] (3) After the above-mentioned pure magnesium melt is degassed and refined, pure zinc and pure tin are added to the pure magnesium melt to obtain a magnesium alloy melt;

[0053] (4) After the above-mentioned magnesium alloy melt is kept at 700°C for 10-20 minutes, the magnesium-calcium and magnesium-yttrium intermediate alloys are added to the magnesium alloy melt. After it is completely melted, the melt...

Embodiment 3

[0061] Taking the Mg-1.5Zn-0.8Sn-0.08Ca-0.3Y alloy as an example, the ingredients are prepared according to the mass percentage of the alloy:

[0062] (1) Pass the protective gas into the melting furnace, the protective gas can be argon or SF 6 and CO 2 The mixed gas, put the pure magnesium ingot into the crucible and heat and melt at the temperature of 700 ℃;

[0063] (2) After the magnesium ingot is melted, the temperature is lowered to 680°C, and the impurities and oxide layer on the surface of the melt are removed by slag removal to obtain a pure magnesium melt;

[0064] (3) After the above-mentioned pure magnesium melt is degassed and refined, pure zinc and pure tin are added to the pure magnesium melt to obtain a magnesium alloy melt;

[0065] (4) After the above-mentioned magnesium alloy melt is kept at 700°C for 10-20 minutes, the magnesium-calcium, magnesium-yttrium intermediate alloy is added to the magnesium alloy melt, and the magnesium-zirconium, magnesium-gadol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com