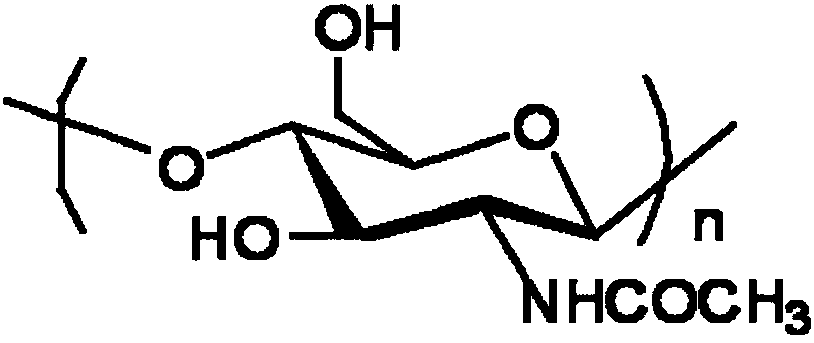

Preparation method of chitin oligose with single degree of polymerization

A technology of chitosan oligosaccharide and degree of polymerization, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc. , The effect of reducing production costs and stabilizing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In the specific implementation process, the preparation method of chitosan oligosaccharide with a single degree of polymerization of the present invention comprises the following steps:

[0035] (1) Use a pulverizer to pulverize the flake chitin to an appropriate particle size, generally about (80-200 mesh).

[0036] (2) Chitin particles are dispersed in a solvent with 5 times to 50 times the mass, and under strong stirring, chitin dissolves or fully swells in the solvent.

[0037] (3) The reactants are kept at 0°C to 100°C for 1 to 10 hours, the chitin begins to degrade, and the molecular weight gradually decreases. By controlling the reaction temperature and reaction time, chitooligosaccharide solutions with different polymerization degree distributions are obtained.

[0038] (4) methods such as vacuum decompression evaporation solvent, alcohol precipitation, etc. are used to remove the reaction liquid solvent.

[0039](5) After dissolving and filtering chitosan olig...

Embodiment 1

[0044] In the present embodiment, the preparation method of single degree of polymerization chitosan oligosaccharide is as follows:

[0045] At 10°C, 10 g of chitin was slowly added into 200 mL of concentrated hydrochloric acid (36 wt%). After stirring for 6 hours, the chitin was completely dissolved. Raise the reaction temperature to 30° C., stir for 1.5 hours, and then slowly add NaOH solid powder to the reaction solution to neutralize the reaction solution. 1000 mL of ethanol was added to the reaction solution for alcohol precipitation, and the precipitated solid precipitate was filtered, washed with ethanol, and air-dried to obtain 6 g of chitooligosaccharide mixture.

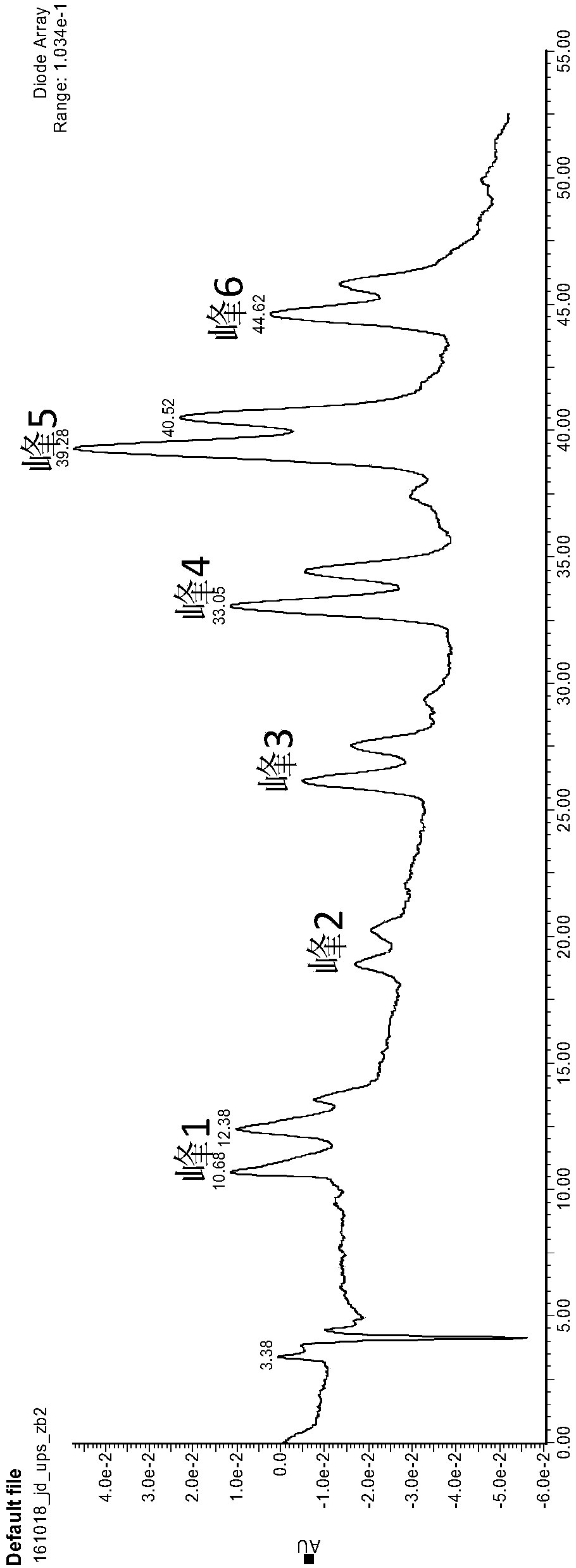

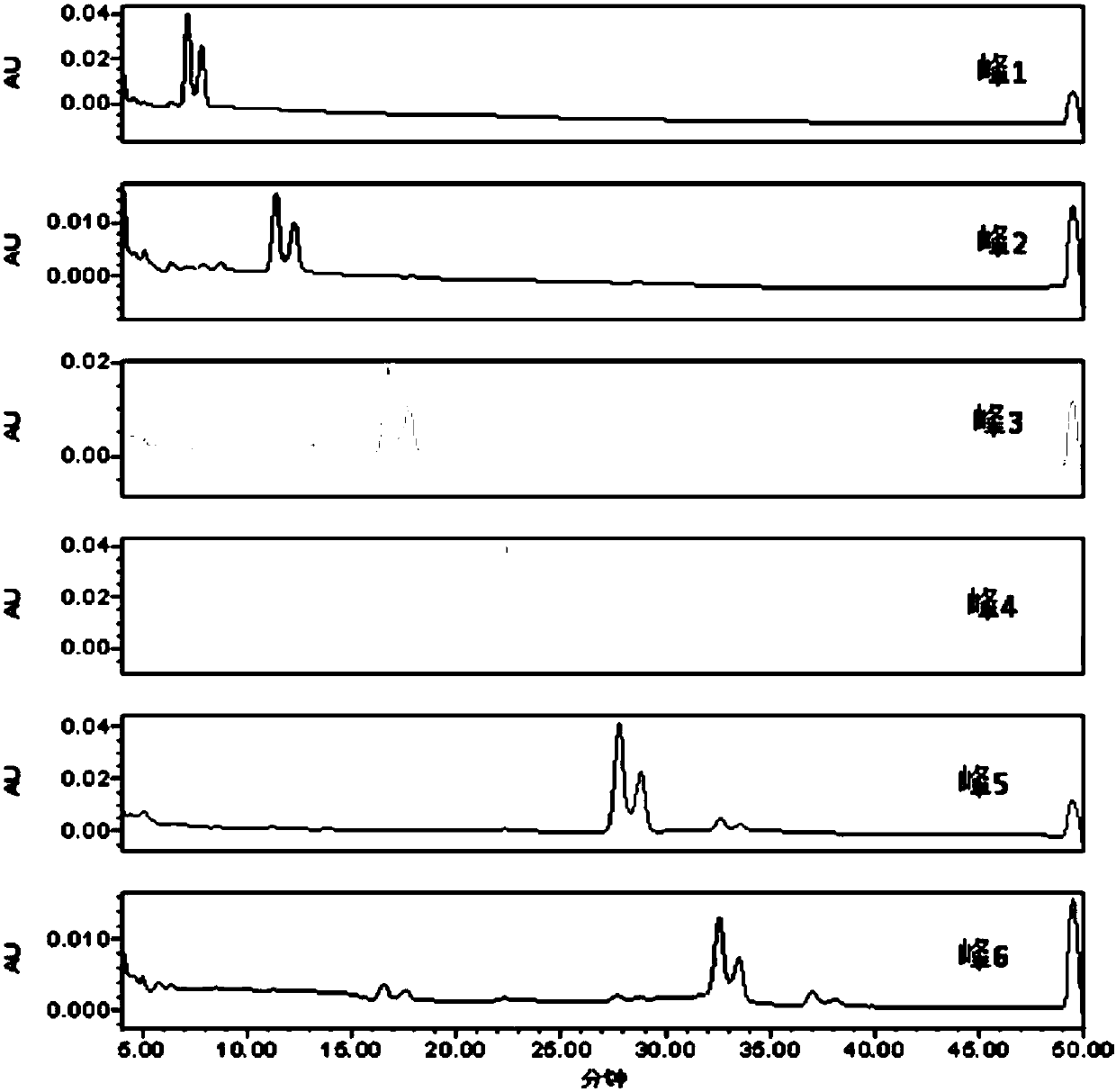

[0046] Take 107mg of chitosan-oligosaccharide mixture, add 4mL of water, dissolve and then add 6mL of acetonitrile, shake well and pass through the membrane, the injection volume is 10mL. Use amide column (XAmide, 50*250mm, 275g) for separation and purification at a flow rate of 70mL / min. In the mobile...

Embodiment 2

[0054] The difference from Example 1 is that in this example, the preparation method of chitosan oligosaccharide with a single degree of polymerization is as follows:

[0055] At 30 °C, 10 g of chitin was slowly added to 500 mL of hexafluoroisopropanol. After stirring for 6 hours, 25 mL of concentrated hydrochloric acid was added after the chitin was completely dissolved. Raise the reaction temperature to 50° C., stir for 1.2 hours, and then spin-evaporate in vacuum at 50° C. to evaporate and recover most of the reaction solvent. The reaction product was washed with ethanol, filtered, and air-dried to obtain 7 grams of chitooligosaccharide mixture.

[0056] Take 500mg of chitosan oligosaccharides, add 20mL of water, dissolve and then add 30mL of acetonitrile, shake well and pass through the membrane, the injection volume is 50mL. Use amide column (XAmide, 100*250mm, ) for separation and purification at a flow rate of 280mL / min. In the mobile phase, phase A is acetonitrile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com