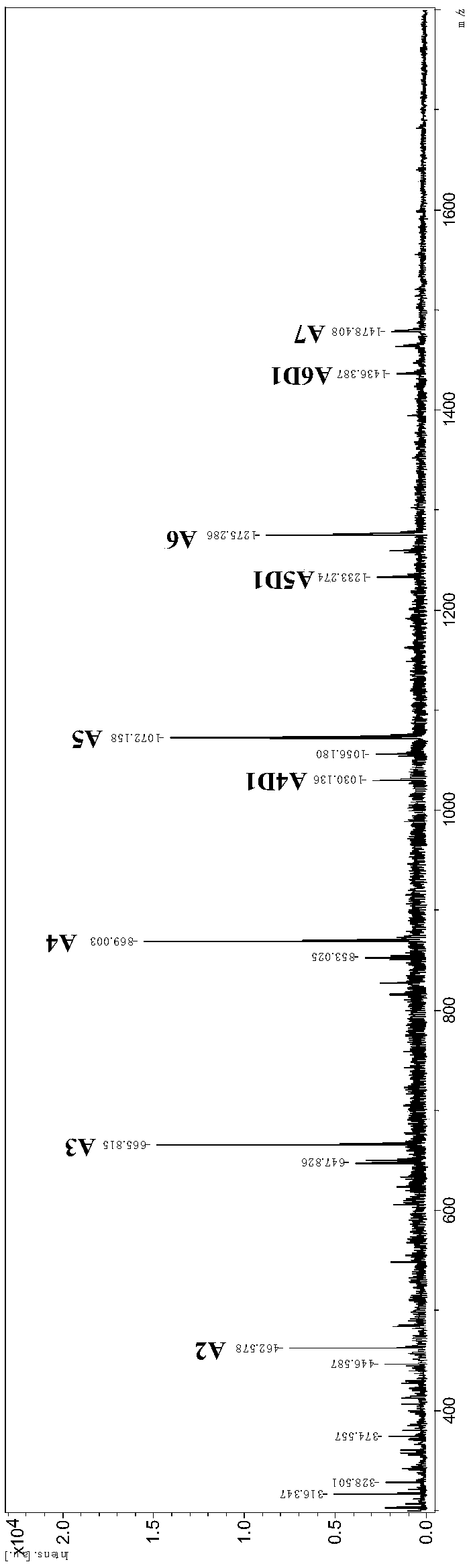

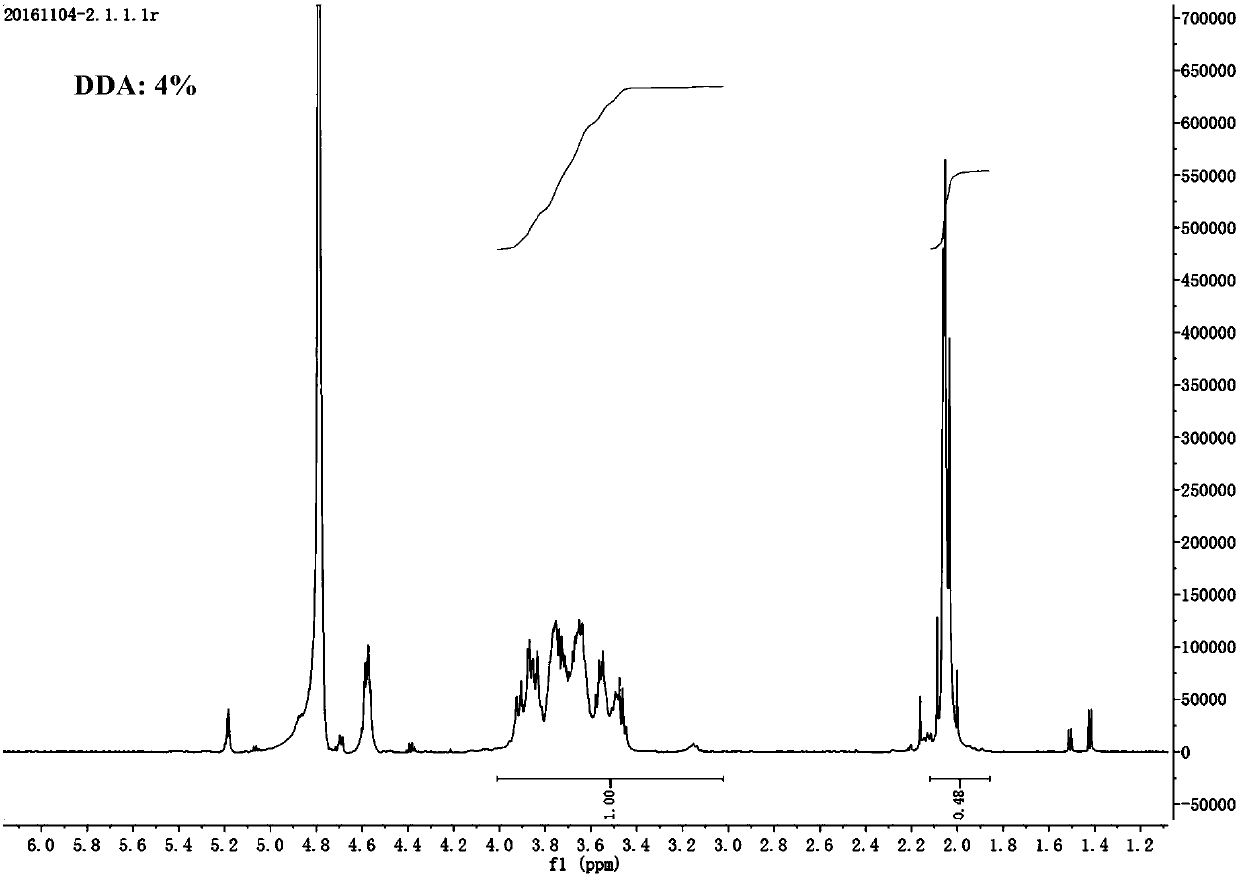

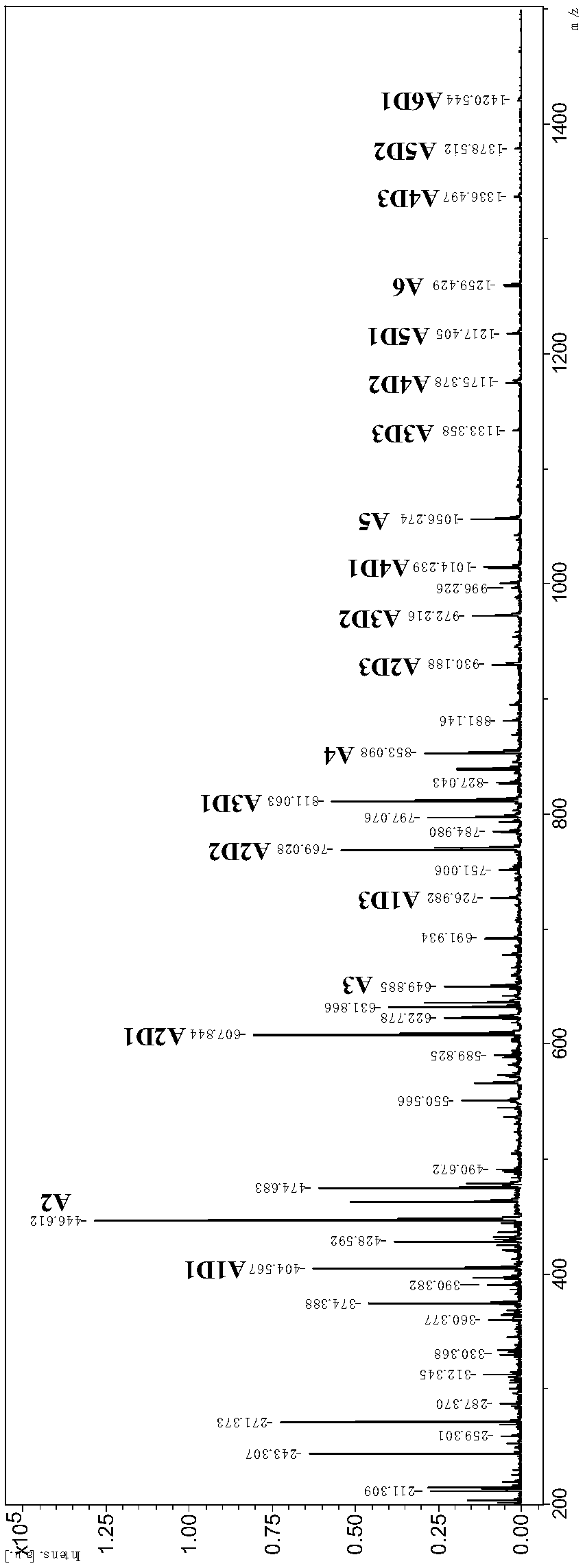

Preparation method of chitosan oligosaccharide of complex structure with adjustable degree of polymerization and degree of deacetylation

A technology with deacetylation degree and complex structure, which is applied in the preparation of sugar derivatives, chemical instruments and methods, amino sugars, etc., can solve the problems of effective control, difficult to achieve the degree of polymerization and deacetylation of chitosan oligosaccharides, and achieve by-products less, easy to batch production, and easy reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In specific implementation process, the preparation method of chitosan oligosaccharide of complex structure of the present invention comprises the following steps:

[0038] (1) Use a pulverizer to pulverize the flake chitin to an appropriate particle size, generally about (80-200 mesh).

[0039] (2) Chitin particles are dispersed in 5 times to 50 times of solvent, and under strong stirring, chitin dissolves or fully swells in the solvent.

[0040] The solvent for dissolving chitin is hexafluoroisopropanol, hexafluoroacetone, dichloroethanol, dimethylformamide containing lithium chloride, dimethylacetamide containing lithium chloride, N-methylmorpholine oxide, Concentrated hydrochloric acid, concentrated sulfuric acid, concentrated phosphoric acid, methanesulfonic acid, formic acid, dichloroacetic acid, trichloroacetic acid or a mixture of two or more, the amount of solvent used is 5 to 50 times the mass of chitin.

[0041] When weakly acidic solvents are used: hexafluo...

Embodiment 1

[0048] At 10°C, 10 g of chitin was slowly added into 200 mL of concentrated hydrochloric acid (36 wt%). After stirring for 6 hours, chitin was completely dissolved. Raise the reaction temperature to 30° C., stir for 1 hour, and then slowly add NaOH solid powder to the reaction solution to neutralize the reaction solution. 1000 mL of ethanol was added to the reaction solution for alcohol precipitation, and the precipitated solid precipitate was filtered, washed with ethanol, and air-dried to obtain 6 grams of small molecule chitin and chitooligosaccharides.

Embodiment 2

[0050] At 30°C, 10g of chitin was slowly added into 500mL of hexafluoroisopropanol. After stirring for 6 hours, 25 mL of concentrated hydrochloric acid was added after the chitin was completely dissolved. Raise the reaction temperature to 50° C., stir for 1.2 hours, and then spin-evaporate in vacuum at 50° C. to evaporate and recover most of the reaction solvent. The reaction product was washed with ethanol, filtered, and air-dried to obtain 7 grams of chitin-oligosaccharide mixture with small molecular weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com