Compound microorganism bacterium agent as well as preparation method and application thereof

A compound microbial inoculum, compound microorganism technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem that the speed and efficiency have not yet reached the requirements of large-scale engineering applications, the treatment effect is not ideal, and engineering applications problems such as limited value, to achieve the effects of fast reproduction, low price and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method for the above-mentioned composite microbial bacterial agent, comprising the following steps: separately fermenting Bacillus circulans, Bacillus spp., Stenotrophomonas maltophilia, Bacillus cereus, Sphingomonas spp. and Paleobacterium pallidum for 24 hours After mixing; centrifuge and filter the mixed composite microorganisms to collect the bacterial cells to obtain the composite microorganism bacterial agent.

[0033] In the preparation method of the present invention, the fermentation medium preferably includes components at the following concentrations: 3-8 g / L of yeast extract powder, 6-16 g / L of tryptone and 6-16 g / L of sodium chloride. The fermentation medium of the present invention contains yeast extract powder, and the concentration of the yeast extract powder is preferably 4-6 g / L, more preferably 5 g / L. The fermentation medium of the present invention contains tryptone, and the concentration of the trypt...

Embodiment 1

[0038] Activated sludge collected from the sewage treatment plant of berberine antibiotic pharmaceutical wastewater, obtained after domestication, separation and purification: Pallidum. Add 6 bacteria into the liquid culture medium with the formula of 0.5% yeast extract powder, 1% tryptone and 1% sodium chloride respectively. It is fermented and produced at a temperature of 25°C, a pH of 7, and a dissolved oxygen (DO) of 2-4 mg / L. Control the water content of the 6 bacteria within 2%, then add 1% glycerin as a protective agent, and then centrifuge at 5000rpm to collect the bacteria for cryopreservation. At this time, the microbial mass can reach 1.0×10 8 cells / g. Before compounding the microbial agent, mix 6 bacteria according to the ratio of biomass 1:1:1:1:1:1, and set aside.

[0039] The composite microbial inoculum prepared in above-mentioned embodiment 1 is tested:

[0040] Experiment 1

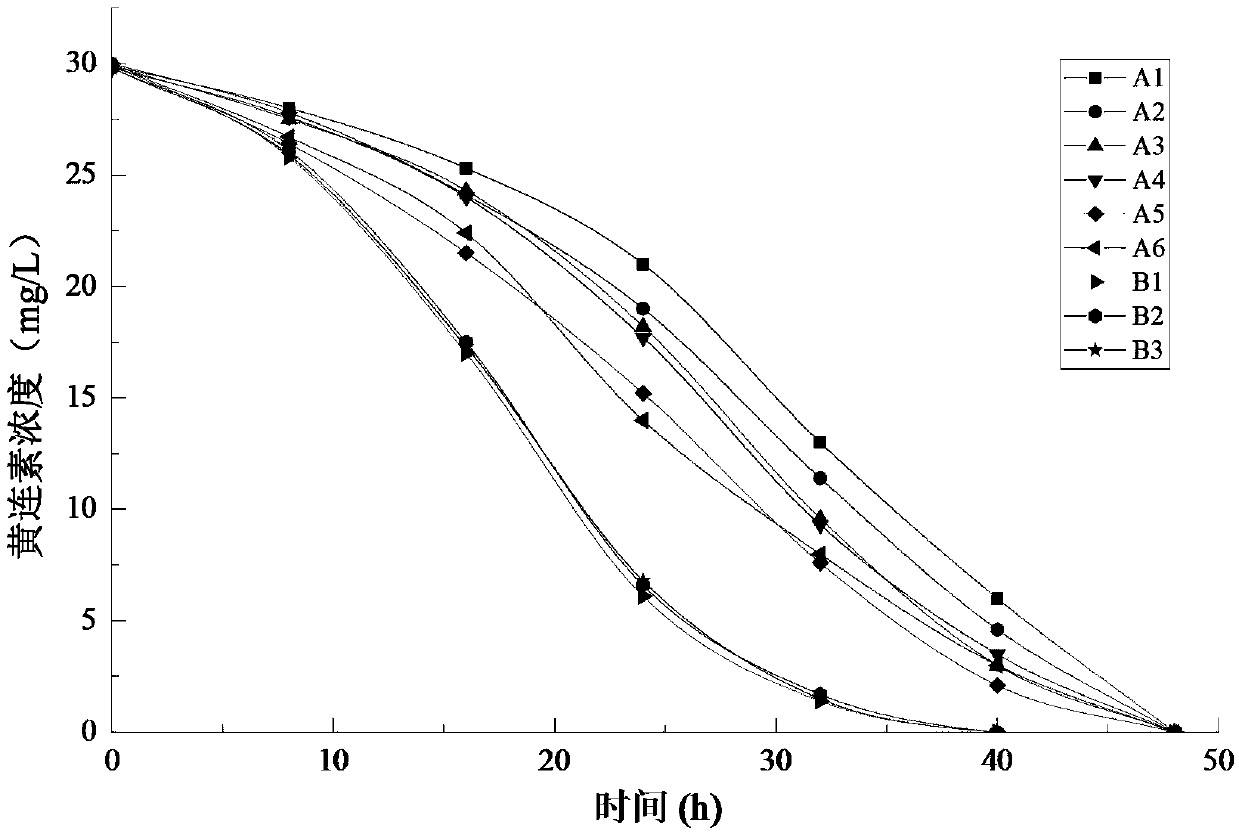

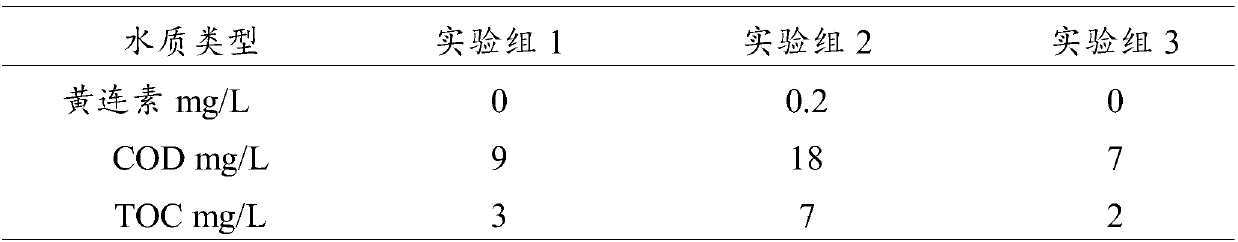

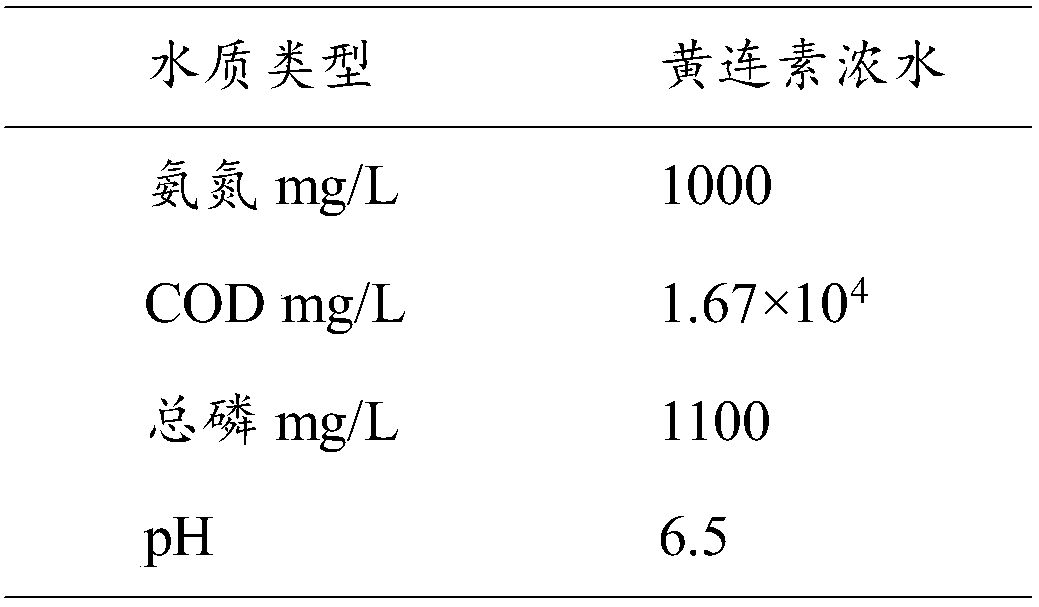

[0041] The berberine standard product was prepared into a berberine solution wi...

Embodiment 2

[0062] Activated sludge collected from the sewage treatment plant of berberine antibiotic pharmaceutical wastewater, obtained after domestication, separation and purification: Pallidum. Add 6 bacteria into the liquid culture medium with the formula of 0.5% yeast extract powder, 1% tryptone and 1% sodium chloride respectively. It is fermented and produced at a temperature of 25°C, a pH of 7, and a dissolved oxygen (DO) of 2-4 mg / L. Control the water content of the 6 bacteria within 2%, then add 1% glycerin as a protective agent, and then centrifuge at 5000rpm to collect the bacteria for cryopreservation. At this time, the microbial mass can reach 1.0×10 8 cells / g. Before compounding the microbial agent, mix 6 bacteria according to the ratio of biomass 1:1:1:1:1:1, and set aside.

[0063] The single bacterium that above-mentioned embodiment 1 and embodiment 2 prepare and experiment with composite microbial inoculum:

[0064] A berberine solution with a concentration of 30 mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com