A kind of mineral gold extraction method based on mercury-free liquid alloy

A technology of liquid alloy and extraction method, which is applied in the field of extracting gold from ore powder with mercury-free liquid alloy, can solve the problems of lack of process methods, etc., and achieve the effects of safe and convenient operation process, simple equipment, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

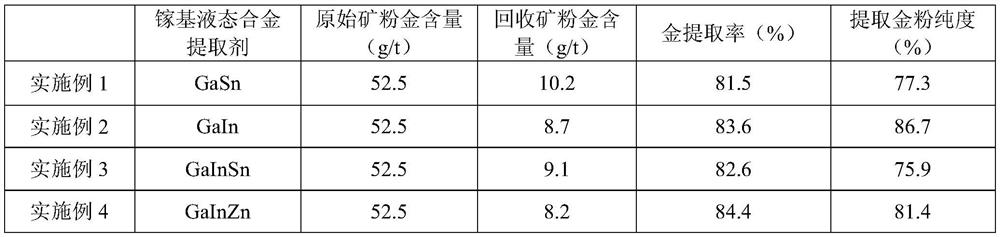

Embodiment 1

[0043]A gallium-tin binary alloy is selected as the extractant, the tin element in the gallium-tin binary alloy accounts for 20% by mass, and the rest is gallium element, and the melting point of the gallium-tin binary alloy is 19°C. Put the gallium-tin binary alloy in a quartz vessel, soak it in 3% dilute hydrochloric acid aqueous solution, add gold-containing ore powder, the powder particle size of the gold-containing ore powder is 20-100 mesh, the difference between the ore powder and the gallium-tin binary alloy The volume ratio is 2:1, heated to 65°C, and continuously stirred with a magnetic stirring device for 6 hours to ensure that the ore powder and the liquid alloy are fully mixed to obtain a mixed solution. Stop stirring, and let the mixture stand for 1.5 hours. Due to the difference in density between the gallium-tin binary alloy and the ore powder, it will separate itself, and the gallium-tin binary alloy will sink to the bottom due to its higher density. Use a gau...

Embodiment 2

[0046] The gallium-indium binary alloy is selected as the extraction agent, the mass percentage of indium element in the gallium-indium binary alloy is 15%, and the rest is gallium element, and the melting point of the gallium-indium binary alloy is 15°C. Put the gallium-indium binary alloy in a quartz vessel, soak it in 3% dilute hydrochloric acid aqueous solution, add gold-containing ore powder, the powder particle size of the gold-containing ore powder is 20-100 mesh, and the ore powder and gallium-indium binary alloy The volume ratio is 2:1, heated to 80°C, and continuously stirred for 4 hours with a magnetic stirring device to ensure that the ore powder and the liquid alloy are fully mixed to obtain a mixed solution. Stop stirring, and let the mixture stand for 2 hours. Due to the difference in density between the gallium-indium binary alloy and the ore powder, it will separate itself, and the gallium-indium binary alloy will sink to the bottom due to its high density. Us...

Embodiment 3

[0049] The gallium indium tin ternary alloy is selected as the extractant, the mass percentage of the indium element in the gallium indium tin ternary alloy is 20%, the mass percentage of the tin element is 10%, and the rest is gallium element, gallium indium tin The melting point of the ternary alloy is 10°C. Put the gallium indium tin ternary alloy in a quartz vessel, soak it in 3% dilute hydrochloric acid aqueous solution, add gold-containing ore powder, the particle size of the gold-containing ore powder is 20-100 mesh, and the ore powder and gallium indium tin ternary The volume ratio of the alloy is 3:1, heated to 45°C, and continuously stirred for 12 hours with a magnetic stirring device to ensure that the ore powder and the liquid alloy are fully mixed to obtain a mixed solution. Stop stirring, and let the mixture stand for 1 hour. Due to the difference in density between the gallium-indium-tin ternary alloy and the ore powder, it will separate itself, and the gallium-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com