Chemical laboratory waste incineration treatment system

A chemical laboratory and treatment system technology, applied in the field of chemical laboratory waste incineration treatment system, can solve the problems of residents' living environment, life and health threats, and environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

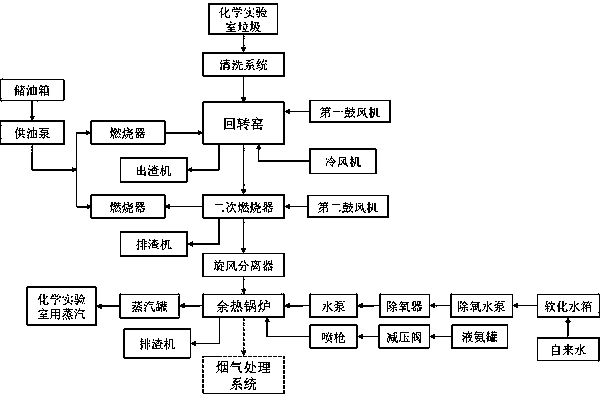

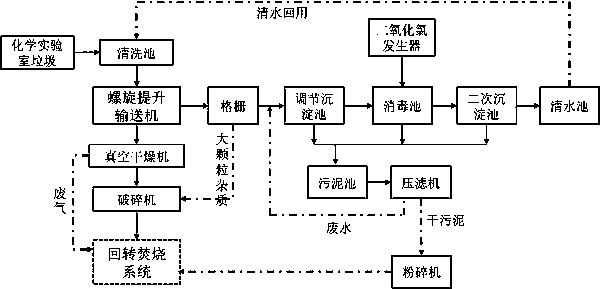

[0029] refer to Figure 1-2 , chemical laboratory waste incineration treatment system, including cleaning system, rotary incineration system, waste heat utilization system and flue gas treatment system; cleaning system includes cleaning pool, screw elevator conveyor and vacuum dryer, chemical laboratory waste is sent to the cleaning pool for After cleaning, it is sent to the vacuum dryer through the screw elevator conveyor, and the vacuum dryer dries the cleaned garbage; the rotary incineration system includes a crusher, a rotary kiln, a secondary burner and a combustion-supporting system, and the vacuum-dried garbage is crushed by a crusher After that, it is sent to the front end of the rotary kiln. The exhaust gas generated by the vacuum dryer is transported to the rotary kiln for combustion treatment through the pipeline. The rotary kiln incinerates the broken garbage, and the ash is discharged from the tail of the rotary kiln. The secondary burner is mixed with air for com...

Embodiment 2

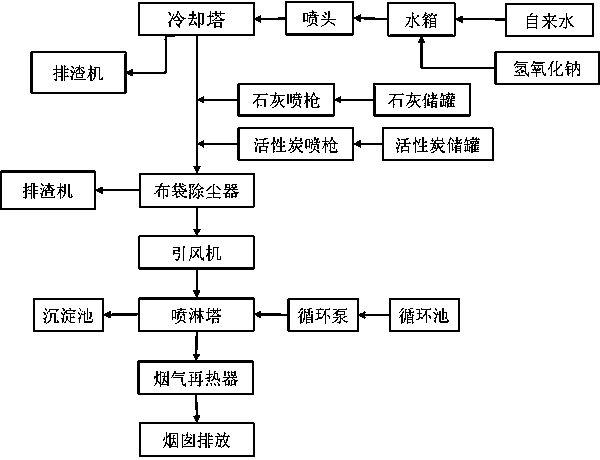

[0038] As a further improvement of Embodiment 1, the flue gas treatment system of the present invention is also provided with a bag filter, a slag discharger, an induced draft fan, a spray tower, a circulation pool, a circulation pump, a sedimentation tank, and a flue gas reheater; The device, induced draft fan, spray tower and flue gas reheater are connected in turn through pipelines; the flue gas treated with lime and activated carbon enters the bag filter, and the suspended particles in the flue gas are collected through the filter bag, and the dust is cleaned in pulse Under the action of the filter bag, it will fall off from the filter bag and be discharged into the solidified landfill in the form of fly ash; after the dust removal and deacidification treatment, the flue gas will be drawn into the spray tower by the induced draft fan, and the flue gas will be treated in the spray tower Water elution acid treatment, the flue gas after water elution acid is heated by the flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com