Method for constructing zinc ion hybrid capacitor

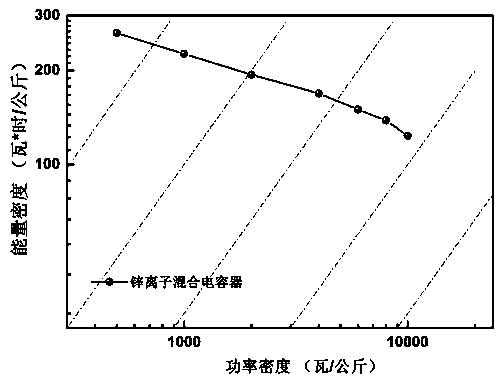

A hybrid capacitor, zinc ion technology, applied in hybrid capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of low potential window, low energy density, potential safety hazards, etc., to achieve high window, high energy density, product Stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Preparation of three-dimensional activated carbon material with high ratio table

[0023] Weigh 10g of ethylenediaminetetraacetic acid monosodium salt, add it to a porcelain boat, put it in an argon atmosphere furnace, heat up to 700°C at a rate of 5°C / min, keep it for 1 h; take it out after cooling to room temperature, wash, dry, Obtain a nitrogen-containing three-dimensional carbon material;

[0024] The obtained nitrogen-containing three-dimensional carbon material was mixed with KOH in a mass ratio of 1:6, placed in an argon atmosphere furnace, heated to 800°C at a rate of 5°C / min, and kept for 1 h; after being cooled to room temperature, it was taken out, washed, and dried to obtain High ratio table three-dimensional activated carbon material.

[0025] 2. Assembly of zinc ion hybrid capacitor

[0026] 1) Prepare a basic aqueous solution of high-concentration salt electrolyte with water and sodium perchlorate in a molar ratio of 1:17;

[0027] 2) Add zinc sulfate to the ...

Embodiment 2

[0031] 1. Preparation of three-dimensional activated carbon material with high ratio table

[0032] Weigh 10g of ethylenediaminetetraacetic acid tetrasodium salt, add it to a porcelain boat, put it in an argon atmosphere furnace, heat it up to 900°C at a rate of 10°C / min, keep it for 0.5 h; take it out after cooling down to room temperature, wash and dry it, Obtain a nitrogen-containing three-dimensional carbon material;

[0033] The obtained nitrogen-containing three-dimensional carbon material was mixed with KOH according to a mass ratio of 1:8, placed in an argon atmosphere furnace, heated to 900°C at a rate of 1°C / min, and kept for 2h; after being cooled to room temperature, it was taken out, washed and dried to obtain high Compare table three-dimensional activated carbon cathode material.

[0034] 2. Assembly of zinc ion hybrid capacitor

[0035] 1) Prepare a basic aqueous solution of high-concentration salt electrolyte with a molar ratio of water and potassium acetate of 1:27; ...

Embodiment 3

[0040] 1. Preparation of three-dimensional activated carbon cathode material

[0041] Weigh 10g of ethylenediaminetetraacetic acid disodium salt into a porcelain boat, put it in an argon atmosphere furnace, heat up to 500°C at a rate of 10°C / min, keep it for 2h; take it out after cooling to room temperature, wash and dry, Nitrogen three-dimensional carbon material;

[0042] The obtained nitrogen-containing three-dimensional carbon material was mixed with KOH according to a mass ratio of 1:4, placed in an argon atmosphere furnace, heated to 700°C at a rate of 10°C / min, kept for 2h, then taken out after cooling to room temperature, washed and dried to obtain High ratio table three-dimensional activated carbon cathode material.

[0043] 2. Assembly of zinc ion hybrid capacitor

[0044] 1) Prepare a basic aqueous solution of high-concentration salt electrolyte with a molar ratio of water and potassium acetate of 1:15;

[0045] 2) Add zinc perchlorate to the basic aqueous electrolyte solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com