Anti-infection coating and preparation method thereof

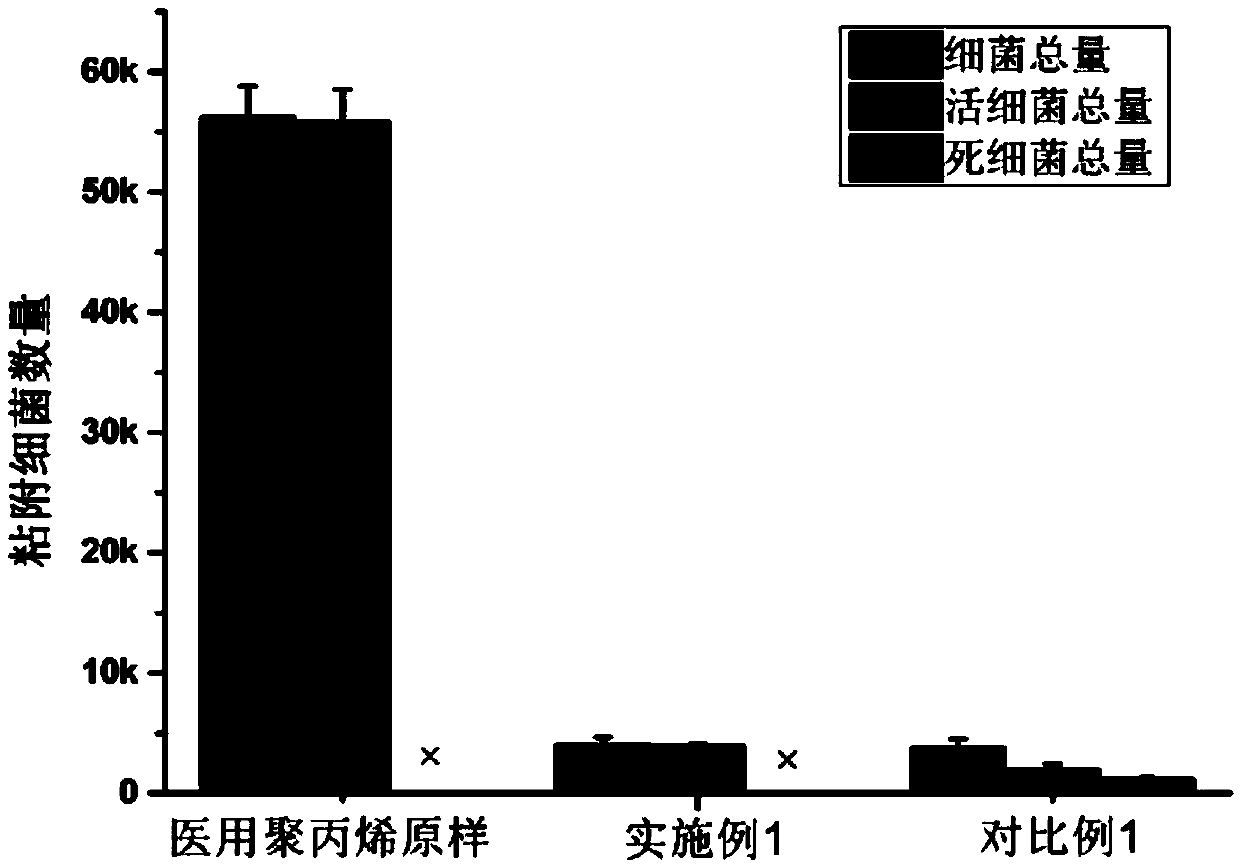

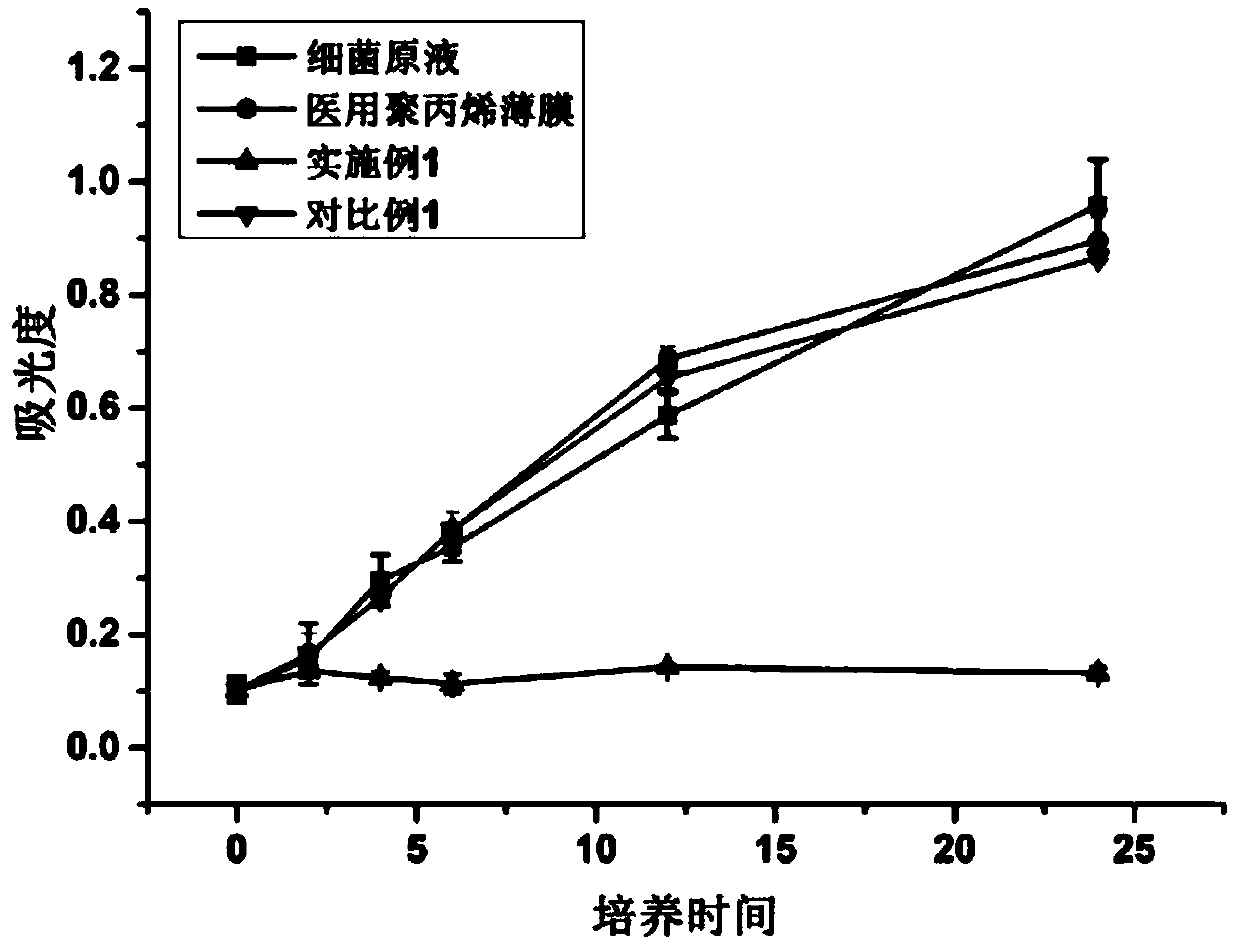

An anti-infection and coating technology, which is applied in coating, medical science, surgery, etc., can solve the problems of adhesion and accumulation of dead bacterial debris, inability to inhibit bacterial reproduction for a long time, non-on-demand release of bactericidal substances, etc., to reduce bacteria The risk of infection, reducing bacterial adhesion, solving the effect of poor persistence of antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of anti-infection coating, comprises the following steps:

[0029] a) coating the surface of the medical polymer material with a photoinitiator to obtain a base material;

[0030] b) Place the base material obtained in step a) in a mixed solution comprising anti-adhesive monomers, pH-responsive polymerizable monomers and polyethylene glycol diacrylate, and carry out ultraviolet crosslinking reaction to obtain gel-coated layer material;

[0031] c) chemically loading the material with the gel coat on the surface obtained in step b) with antibiotics to obtain an anti-infection coating.

[0032] In the invention, firstly, the surface of the medical polymer material is coated with a photoinitiator to obtain a base material. In the present invention, there is no special limitation on the type and source of the medical polymer material, and commercially available products well known to those skilled in the art can be used....

Embodiment 1

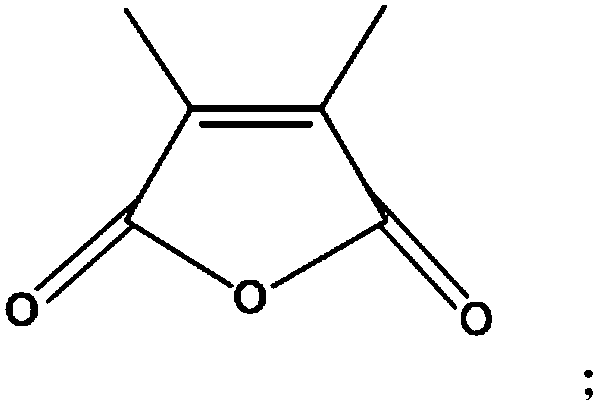

[0069] (1) Synthesis of pH-responsive polymerizable monomers: Dissolve 0.16g of 2-aminoethyl methacrylate in 20mL of DMF, then add 0.19g of 2,3-dimethylmaleic anhydride in DMF solution, overnight at room temperature After stirring and rotary evaporation to remove part of the DMF solvent, the precipitated sample was dissolved in chloroform three times and freeze-dried to obtain the product.

[0070] The NMR data are as follows: 1 H NMR(400MHz,DMSO):δ11.5(s,1H),δ8.33(s,1H),δ6.56(s,1H),δ6.35(s,1H),δ5.79(s, 1H), δ4.81(d, 2H), δ4.58-5.09(m, 2H), δ3.15-3.60(m, 2H), δ2.43(s, 6H).

[0071] (2) Evenly drop the acetone solution of photoinitiator benzophenone with a mass concentration of 5% on the surface of the medical polypropylene film, and dry it in the dark for 30 minutes; then place the sample in a methanol solution with a mass ratio of 20:8:0.5. In the aqueous solution of monopolyethylene glycol acrylate, the pH-responsive polymerized monomer obtained in step (1) and polyethylen...

Embodiment 2

[0083] (1) Synthesis of pH-responsive polymerizable monomers: Dissolve 0.16g of 2-aminoethyl methacrylate in 20mL of DMF, then add a DMF solution containing 0.19g of 2-methylmaleic anhydride, stir overnight at room temperature, spin After evaporating part of the DMF solvent, the precipitated sample was dissolved in chloroform three times, and freeze-dried to obtain the product.

[0084] The NMR data are as follows: 1 H NMR(400MHz,DMSO):δ11.5(s,1H),δ8.33(s,1H),δ6.56(s,1H),δ6.35(s,1H),δ5.79(s, 1H), δ4.81(d, 2H), δ4.58-5.09(m, 2H), δ3.15-3.60(m, 2H), δ2.43(s, 3H).

[0085] (2) Evenly drop the acetone solution of photoinitiator benzophenone with a mass concentration of 5% on the surface of the medical polypropylene film, and dry it in the dark for 30 minutes; then place the sample in a methanol solution with a mass ratio of 15:5:0.5. In the aqueous solution of monopolyethylene glycol acrylate, the pH-responsive polymerized monomer obtained in step (1) and polyethylene glycol dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com