Preparation method of zinc cadmium sulfide/bismuth oxybromide composite visible light catalyst

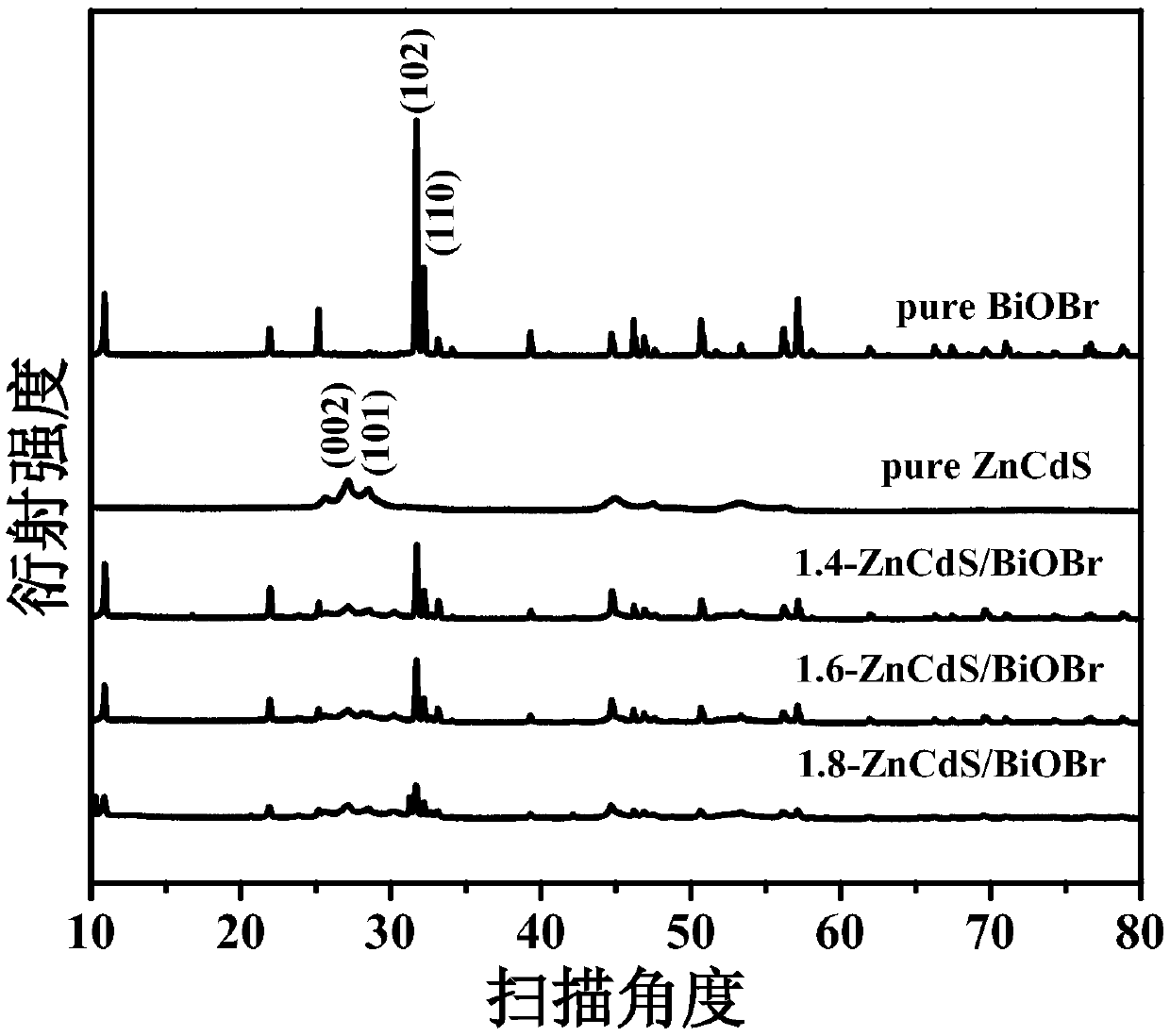

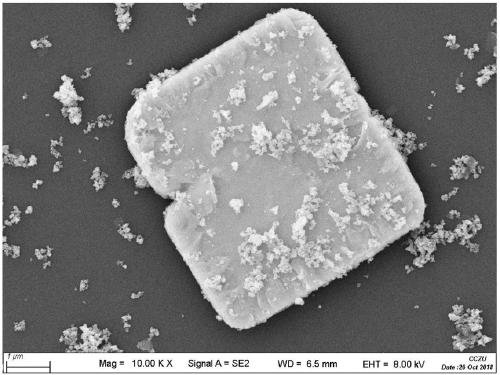

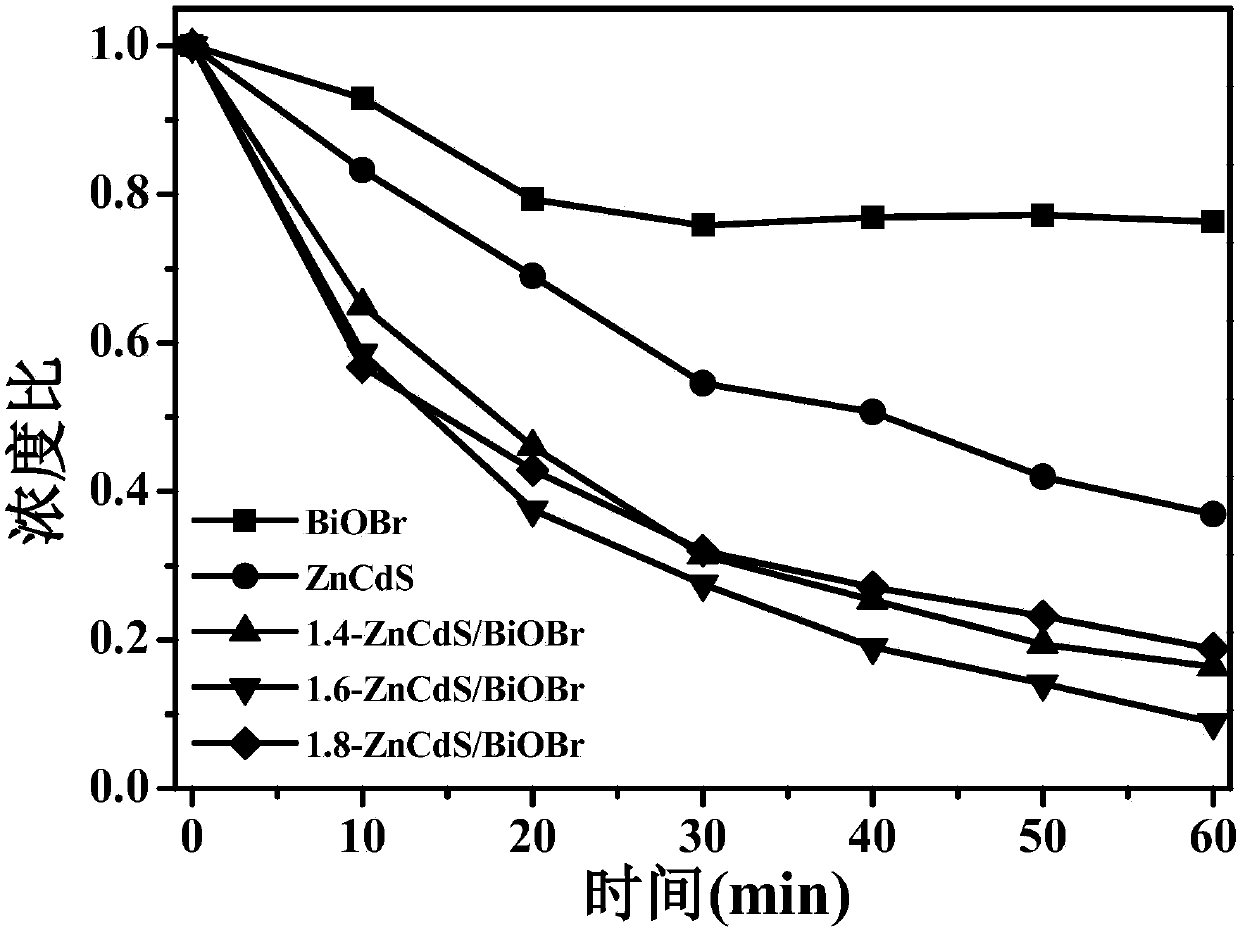

A technology of bismuth oxybromide and zinc cadmium sulfide is applied in the field of preparation of zinc cadmium sulfide/bismuth oxybromide composite visible light catalyst, and can solve the problems of reducing the photocatalytic efficiency of bismuth oxybromide, narrow absorption range, easy recombination of photogenerated charges, etc. The effect of short degradation time, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of zinc cadmium sulfide: Measure 5mL of distilled water and add 1.4875g of zinc nitrate hexahydrate and 1.5425g of cadmium nitrate tetrahydrate at the same time, stir for 0.5h, add dropwise 10ml of sodium hydroxide solution (2.4006g), stir 0.5h, then add 1.5224g of thiourea to the above solution, transfer the reactant to a hydrothermal reaction kettle, react at 180°C for 12h, cool, centrifuge, wash, and dry;

[0021] (2) Preparation of bismuth oxybromide: Measure 60mL of distilled water and add 1.9404g of bismuth nitrate pentahydrate and 0.4116g of sodium bromide at the same time, stir for 0.5h, transfer the reactants to a hydrothermal reaction kettle, and react at 160°C for 24h , cooling, centrifugation, washing, drying;

[0022] (3) Preparation of zinc cadmium sulfide / bismuth oxybromide composite photocatalyst: add 0.1g bismuth oxybromide and 0.14g zinc cadmium sulfide to 10mL distilled water respectively, ultrasonication for 0.5h each, then add zinc c...

Embodiment 2

[0024] (1) Preparation of zinc cadmium sulfide: Measure 5mL of distilled water and add 1.4875g of zinc nitrate hexahydrate and 1.5425g of cadmium nitrate tetrahydrate at the same time, stir for 0.5h, add dropwise 10ml of sodium hydroxide solution (2.4006g), stir 0.5h, then add 1.5224g of thiourea to the above solution, transfer the reactant to a hydrothermal reaction kettle, react at 180°C for 12h, cool, centrifuge, wash, and dry;

[0025] (2) Preparation of bismuth oxybromide: Measure 60mL of distilled water and add 1.9404g of bismuth nitrate pentahydrate and 0.4116g of sodium bromide at the same time, stir for 0.5h, transfer the reactants to a hydrothermal reaction kettle, and react at 160°C for 24h , cooling, centrifugation, washing, drying;

[0026] (3) Preparation of zinc cadmium sulfide / bismuth oxybromide composite photocatalyst: Add 0.1g bismuth oxybromide and 0.16g zinc cadmium sulfide to 10mL distilled water respectively, ultrasonication for 0.5h each, then add zinc c...

Embodiment 3

[0028] (1) Preparation of zinc cadmium sulfide: Measure 5mL of distilled water and add 1.4875g of zinc nitrate hexahydrate and 1.5425g of cadmium nitrate tetrahydrate at the same time, stir for 0.5h, add dropwise 10ml of sodium hydroxide solution (2.4006g), stir 0.5h, then add 1.5224g of thiourea to the above solution, transfer the reactant to a hydrothermal reaction kettle, react at 180°C for 12h, cool, centrifuge, wash, and dry;

[0029] (2) Preparation of bismuth oxybromide: Measure 60mL of distilled water and add 1.9404g of bismuth nitrate pentahydrate and 0.4116g of sodium bromide at the same time, stir for 0.5h, transfer the reactants to a hydrothermal reaction kettle, and react at 160°C for 24h , cooling, centrifugation, washing, drying;

[0030] (3) Preparation of zinc cadmium sulfide / bismuth oxybromide composite photocatalyst: add 0.1g bismuth oxybromide and 0.18g zinc cadmium sulfide to 10mL distilled water, respectively, ultrasonication for 0.5h, then add zinc cadmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com