Catalyst for activating persulfate and application of catalyzing persulfate to remove pollutants

A technology for activating persulfate and persulfate, which is applied in the field of environmental pollutant treatment, can solve problems such as the scope of leakage, the presence of heavy metals, and insufficient stability, and achieve friendly and convenient preparation conditions, fast generation rate, and easy separation and recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

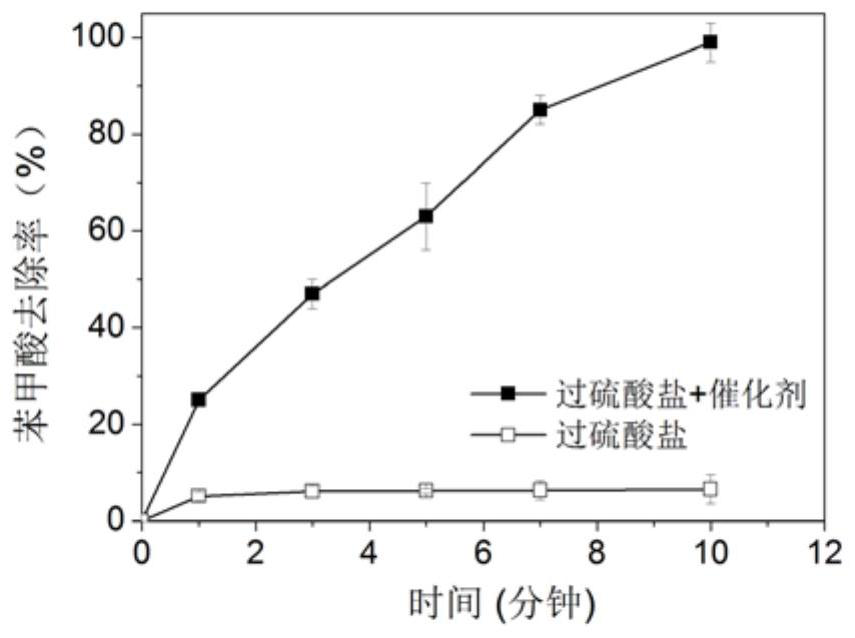

[0048] This example mainly demonstrates the removal of typical organic pollutants in water by this method. Benzoic acid has stable chemical properties and is a representative of highly stable organic pollutants, and its degradation effect can reflect the efficiency of oxidation technology. In a drinking water treatment process that uses surface water as the water source, the initial concentration of benzoic acid in the filtered water to be treated is 2.0 mg / L, the pH of the solution is 7.3, and the water temperature is 20°C.

[0049] The catalyst used in this example is prepared according to the following method: (1) Put 100g of quartz sand (particle size 2~5mm) into 1L of water, and stir rapidly to fully wet; 2) At 25°C, use hydrochloric acid to adjust the pH of the water to 1.0, then add 10g copper sulfate, 40g ferrous sulfate and 200g calcium chloride, mix well, and react for 12 hours; (3) add 40g sodium hydroxide, the pH of the system is 10 at this time, at 25°C at 60-80r ...

Embodiment 2

[0056] The preparation method and application thereof of a kind of persulfate catalyst of the present embodiment are basically the same as embodiment 1, except that:

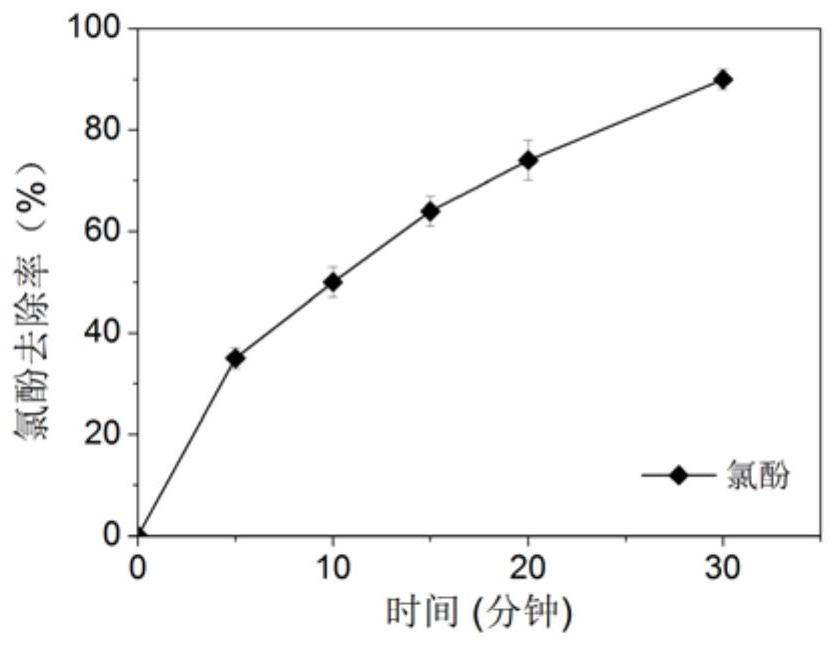

[0057] 1. The treatment object of this example is industrial wastewater, containing 20 mg / L chlorophenol, pH 9.2, and water temperature 25°C;

[0058] 2. When preparing the catalyst, the carrier used is granular activated carbon (Shanxi Xinhua coal-based activated carbon, particle size 1~2cm), the copper salt used is copper chloride, the iron salt used is ferric chloride, and the alkali used is hydroxide Calcium, other with embodiment 1;

[0059] 3. When the catalyst is applied, the dosage of potassium persulfate is 100mg / L, and the dosage of catalyst is 1g / L.

[0060] The processing effect of this embodiment can be found in figure 2 , it can be seen that the present embodiment can remove more than 90% of chlorophenols in a certain industrial wastewater within 30 minutes, and the effect is obvious. Among the...

Embodiment 3

[0062] The preparation method and application thereof of a kind of persulfate catalyst of the present embodiment are basically the same as embodiment 1, except that:

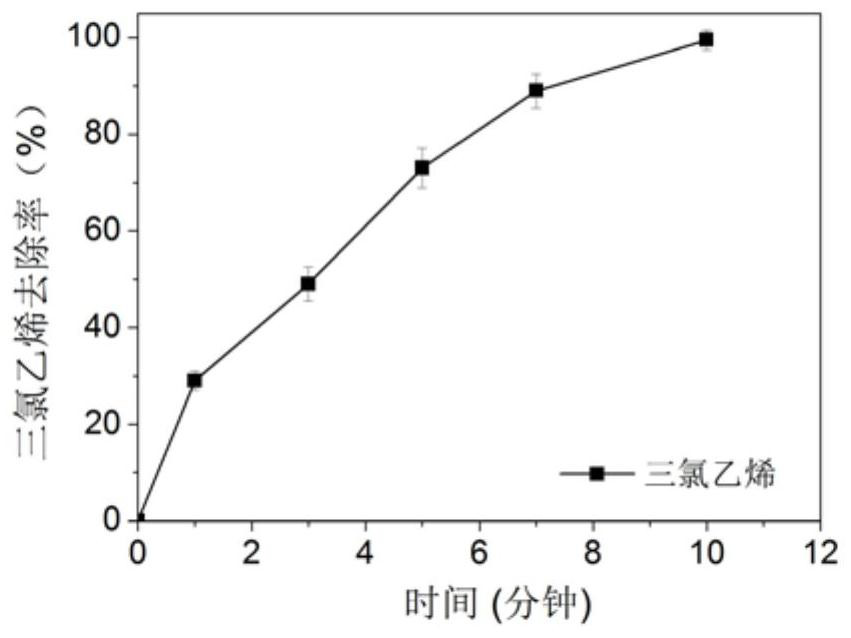

[0063] 1. The treatment object of this embodiment is groundwater, containing 1.5 mg / L trichlorethylene, pH 7.4, and water temperature 16°C;

[0064] 2. When preparing the catalyst, the carrier used is zeolite (particle size 2 ~ 4mm), no iron salt is used, and the others are the same as in Example 1;

[0065] 3. When the catalyst is applied, the dosage of potassium persulfate is 30mg / L, and the dosage of catalyst is 1.5g / L.

[0066] The processing effect of this embodiment can be found in image 3 , it can be seen that the present embodiment almost completely removes trichlorethylene in groundwater within 10 minutes. Wherein, the zeolite-supported catalyst in this embodiment can be reused many times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com