Raw material for preparing barium sulfate and method for preparing barium sulfate by recycling waste barium mud

A technology of barium sulfate and barium mud, which is applied in the direction of chemical instruments and methods, calcium/strontium/barium sulfate, calcium/strontium/barium compounds, etc., can solve the problems of using, being difficult to use, and not being able to be used as products, so as to reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

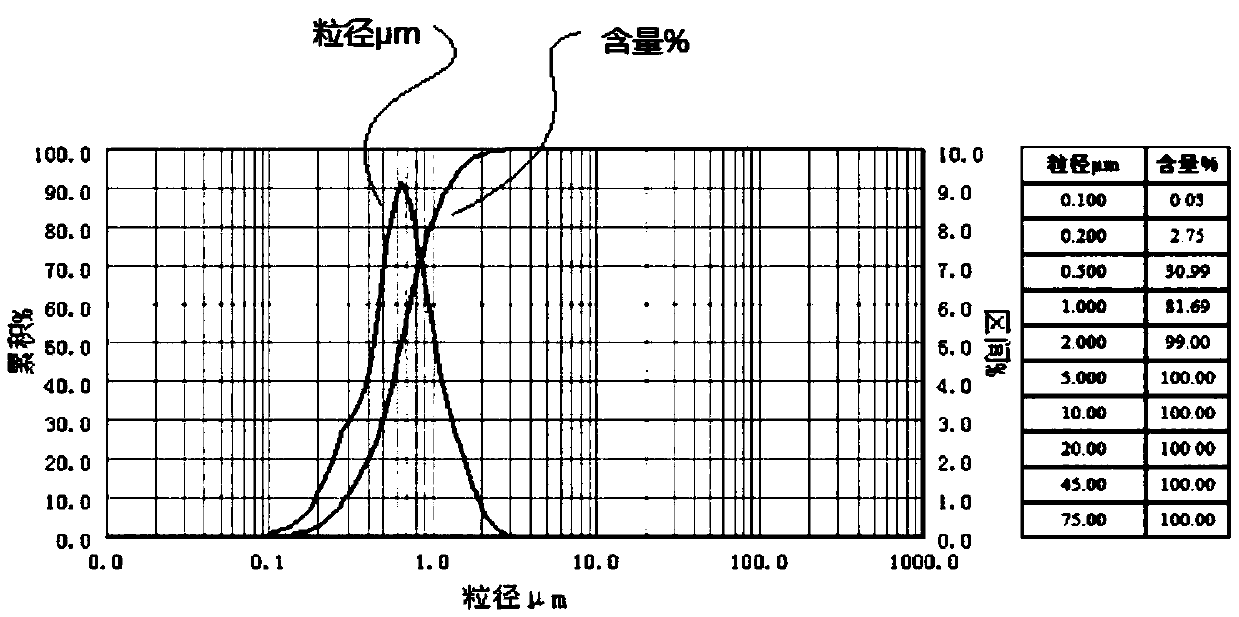

Image

Examples

Embodiment 1

[0032] The waste barium sludge from the bottom of the lye storage tank and lye clarification tank in the chemical compound workshop was piled up in the rain shelter yard for 90 days.

[0033] S1, air-dry the waste barium mud to a moisture content of 15%, and add coke powder with a mass percentage of 20% and a carbon content of 80% to the waste barium mud;

[0034] S2, putting the mixed material into a pulverizer for pulverization, placing the pulverized material in a ceramic crucible, and roasting at 1000° C. for 1 hour to obtain barium sulfide black ash;

[0035] S3, leaching the barium sulfide black ash obtained by roasting with condensed water, the leaching temperature is 75°C, and the leaching time is 60min;

[0036] S4, adding a flocculant with a solution mass percentage of 0.02% to the barium sulfide solution, the flocculant is aluminum sulfate;

[0037] S5, adding a 20% sodium sulfate solution with a mass percentage of 20% by precision filter paper to S4, and heating t...

Embodiment 2

[0060] The waste barium mud from the bottom of the lye storage tank and lye clarification tank of the chemical compound workshop is piled up in the rain shelter yard for 120 days.

[0061] S1, air-drying the waste barium mud to a water content of 12%, adding coke powder with a mass percentage of 33% and a carbon content of 83% to the waste barium mud;

[0062] S2, putting the mixed material into a pulverizer for pulverization, placing the pulverized material in a ceramic crucible, and roasting at 1050° C. for 75 minutes to obtain barium sulfide black ash;

[0063] S3, leaching the barium sulfide black ash obtained by roasting with condensed water, the leaching temperature is 78°C, and the leaching time is 75min;

[0064] S4, adding a flocculant with a solution mass percentage of 0.05% to the barium sulfide solution, the flocculant is aluminum sulfate;

[0065] S5, adding a 23% sodium sulfate solution with a mass percentage of 23% through precision filter paper to S4, and heatin...

Embodiment 3

[0088] The waste barium mud from the bottom of the lye storage tank and lye clarification tank in the chemical compound workshop is piled up in the rain shelter yard for 150 days.

[0089] S1, air-drying the waste barium mud to a water content of 10%, adding coke powder with a mass percentage of 38% and a carbon content of 85% to the waste barium mud;

[0090] S2, putting the mixed material into a pulverizer for pulverization, placing the pulverized material in a ceramic crucible, and roasting at 1150° C. for 1.5 hours to obtain barium sulfide black ash;

[0091] S3, leaching the barium sulfide black ash obtained by roasting with condensed water, the leaching temperature is 80°C, and the leaching time is 90min;

[0092] S4, adding a flocculant with a solution mass percentage of 0.1% to the barium sulfide solution, the flocculant is aluminum sulfate;

[0093] S5, adding a 25% sodium sulfate solution with a mass percentage of 25% by precision filter paper to S4, and heating to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com