Method and application of catalytic activity reactivation of heterogeneous Fenton catalyst

A heterogeneous Fenton, catalytically active technology, applied in the field of environmental engineering, can solve problems such as cycle performance decline, and achieve the effect of reducing energy consumption, improving service life, high economic value and industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

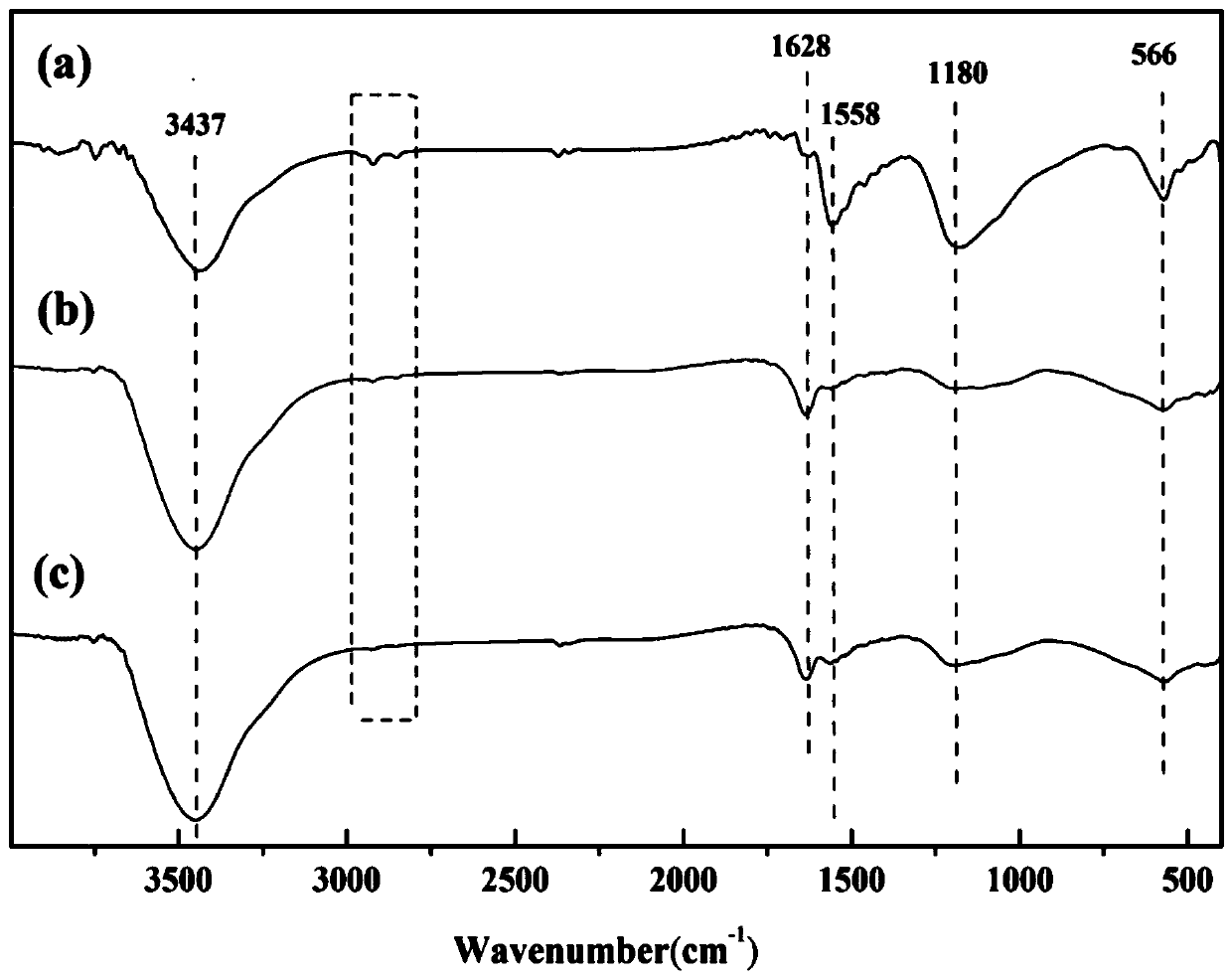

[0037] I) Preparation of ethylenediaminetetraethanol functionalized magnetic graphene oxide catalytic material

[0038] I1) the preparation of graphene oxide is as follows:

[0039] (1) Measure 23mL of concentrated sulfuric acid (98%), pour it into a three-necked flask and then ice-bath it to lower its temperature below 4°C. Subsequently, 1 g of graphite powder and 0.5 g of sodium nitrate were weighed. After it is dispersed in concentrated sulfuric acid, slowly add 3g of potassium permanganate into the mixed solution within 1h, and control the reaction temperature during the addition process not to exceed 10°C; after the addition of potassium permanganate is completed, react below 10°C for 1h.

[0040] (2) The temperature of the mixed solution obtained from the above reaction was raised to 38° C., and allowed to react with stirring at 38° C. for 0.5 h. Subsequently, 80 mL of distilled water was slowly added to the mixed solution. And slowly raise the temperature to 95°C, an...

Embodiment 2

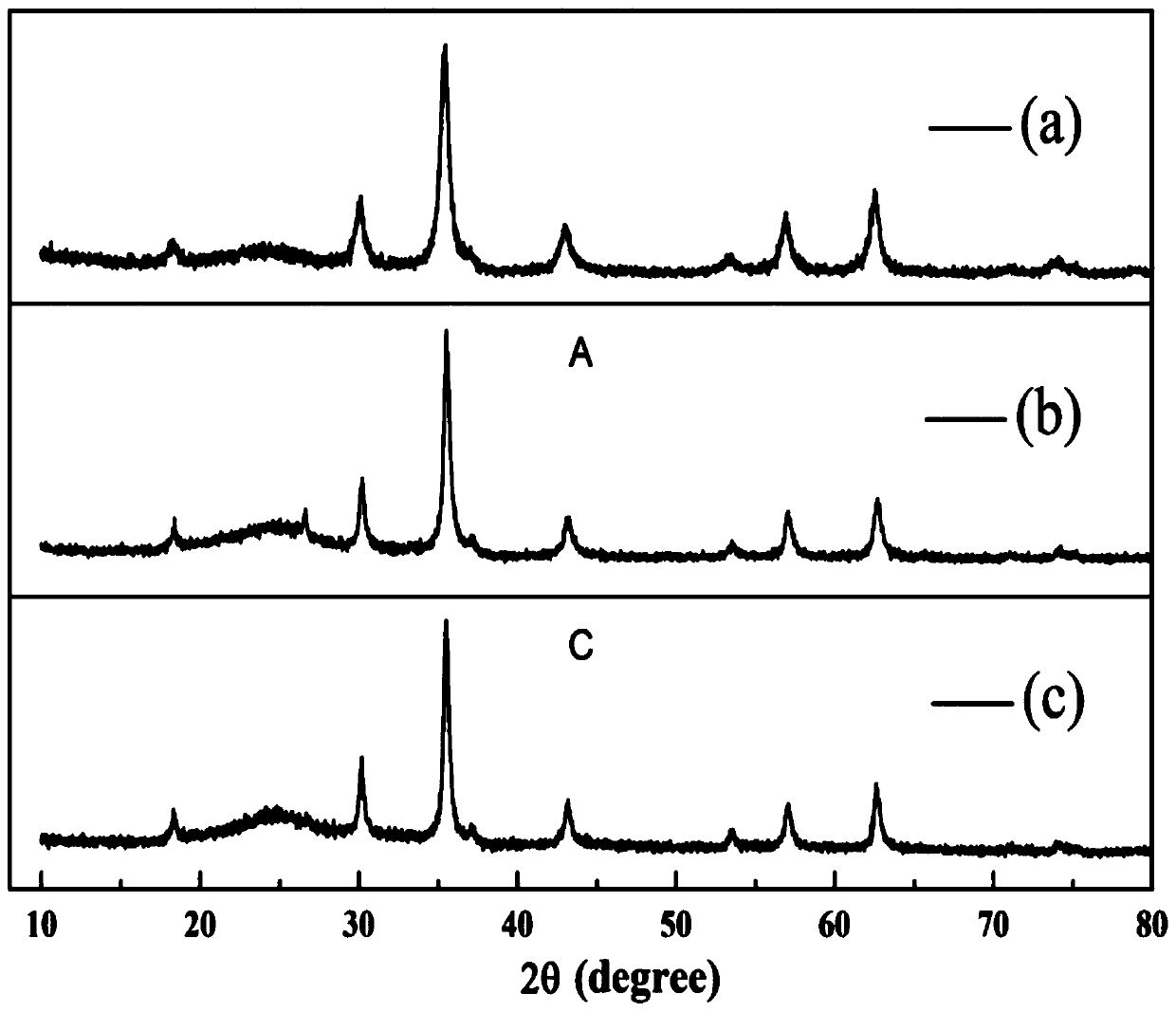

[0058]1) The magnetic ferric ferric oxide catalytic material is prepared by co-precipitation method, and the preparation method is as follows:

[0059] Take 0.01mol FeCl 3 ·6H 2 O and 0.05mol FeSO 4 ·7H 2 O was dissolved in 100mL of water. After it was completely dissolved, an appropriate amount of ammonia water was added to adjust the pH of the solution to 10, and the solution was stirred for 45 minutes to obtain black ferric oxide, followed by magnetic separation, washing, and freeze-drying.

[0060] 2) The iron ferric oxide catalyst prepared in step 1) is used for Fenton degradation, and the process is as in Example 1, step II). Degraded three times.

[0061] 3) The ferric oxide catalyst treated in step 2) is reactivated, and the process is as in step III) of Example 1.

[0062] Figure 5 It is the effect diagram of Fenton degradation of ferric oxide catalyst prepared by co-precipitation method. in Figure 5 (a, b) are the first and fourth cycles of degradation of t...

Embodiment 3

[0064] Material preparation condition is the same as embodiment 1;

[0065] Fenton's degradation condition is the same as embodiment 1;

[0066] The conductive medium in the reactivation experiment under the action of electric field is 0.1mol / L, the sodium chloride solution of 150mL, other conditions are with embodiment 1;

[0067] In the fourth Fenton degradation result, it took 12 minutes to completely degrade methylene blue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com