DTPA (Diethylenetriaminepentaacetic Acid) meta-neutral salt as well as preparation method and application thereof

A technology with neutral salt and general structure, applied in the field of DTPA partial neutral salt synthesis, which can solve the problems of strong irritation, high salt content, and generally low yield, and achieve the effect of good product quality, less by-products, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

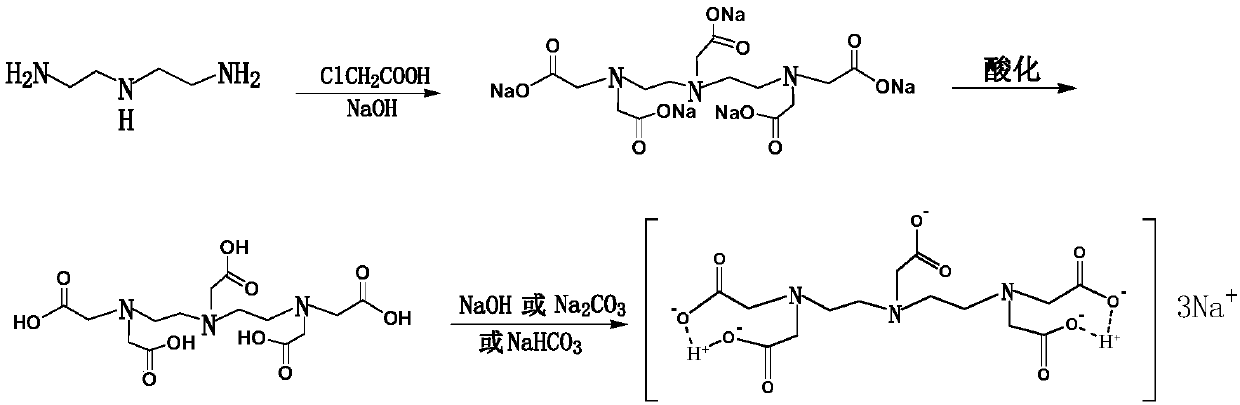

Method used

Image

Examples

Embodiment 1

[0036]A preparation method of neutral salt of DTPA: Weigh 94.5g of chloroacetic acid, dissolve in 74.5g of distilled water, dissolve 40.0g of sodium hydroxide in 120g of distilled water, stir and control the temperature below 35°C, dropwise into the chloroacetic acid solution Add 80g of sodium hydroxide solution, keep the temperature of the reaction system below 35°C during the dropwise addition, add 20.634g of diethylenetriamine dropwise into the mixed solution, and then add the remaining sodium hydroxide solution dropwise into the solution, when the pH value reaches 11.2~ End the titration at 11.5, raise the temperature to 55°C, react for 9 hours, lower the temperature to 35°C, adjust the pH value to 1.5-1.7 with a hydrochloric acid solution with a volume concentration of 50%, let stand overnight, filter with suction, wash with distilled water 3 times, Dry at 120°C to obtain DTPA with a purity of 99.82%. Weigh 12g of sodium hydroxide and dissolve it in 480g of distilled water...

Embodiment 2

[0038] A preparation method of neutral salt of DTPA: Weigh 94.5g of chloroacetic acid, dissolve in 74.5g of distilled water, dissolve 40.0g of sodium hydroxide in 120g of distilled water, stir and control the temperature below 35°C, dropwise into the chloroacetic acid solution Add 70g of sodium hydroxide solution, keep the temperature of the reaction system below 35°C during the dropwise addition, add 20.634g of diethylenetriamine dropwise into the mixed solution, and then add the remaining sodium hydroxide solution dropwise into the solution, when the pH value reaches 11.2~ End the titration at 11.5, raise the temperature to 60°C, react for 8 hours, lower the temperature to 35°C, adjust the pH value to 1.5-1.7 with a hydrochloric acid solution with a volume concentration of 50%, let stand overnight, filter with suction, wash with distilled water 3 times, Dry at 120°C to obtain DTPA with a purity of 99.90%. Weigh 15.9g of sodium carbonate and dissolve in 160g of distilled water...

Embodiment 3

[0040] A preparation method of neutral salt of DTPA: Weigh 94.5g of chloroacetic acid, dissolve in 74.5g of distilled water, dissolve 40.0g of sodium hydroxide in 120g of distilled water, stir and control the temperature below 35°C, dropwise into the chloroacetic acid solution Add 90g of sodium hydroxide solution, keep the temperature of the reaction system below 35°C during the dropwise addition, add 20.634g of diethylenetriamine dropwise into the mixed solution, and then add the remaining sodium hydroxide solution dropwise into the solution, when the pH value reaches 11.2~ End the titration at 11.5, raise the temperature to 65°C, react for 7 hours, lower the temperature to 35°C, adjust the pH value to 1.5-1.7 with a hydrochloric acid solution with a volume concentration of 50%, let stand overnight, filter with suction, wash with distilled water 3 times, Dry at 120°C to obtain DTPA with a purity of 99.88%. Weigh 25.2g of sodium bicarbonate and dissolve it in 400g of distilled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com