Water phase extraction method of erythromycin fermentation broth

A water-phase extraction and fermentation liquid technology, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of high cost, increased cost, and high cost of the extraction process, and achieve simple and easy resin operation, The effect of improving the quality of finished products and reducing extraction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

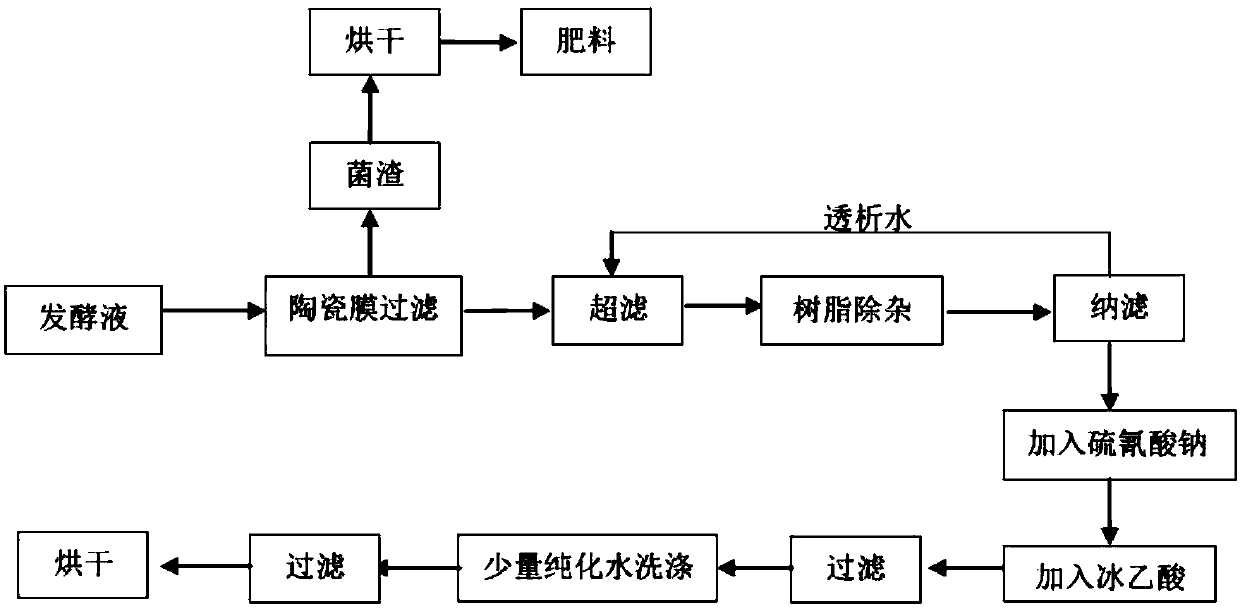

[0054] 200L of erythromycin fermentation broth, with a titer of 8000u / ml, was filtered through a 50nm ceramic membrane at a temperature of 8°C, and the resulting filtrate was ultrafiltered through a coiled membrane with a molecular weight cut-off of 30,000. The obtained ultrafiltrate is purified by LX-98 resin column to obtain a column liquid, and the column liquid is nanofiltered through a nanofiltration membrane with a molecular weight cut-off of 100 until the titer of the concentrated solution is 15000u / ml. In the concentrated solution, add sodium thiocyanate with a molar ratio of 1.0 to erythromycin, finish adding in 1 hour, continue to react for 1 hour after adding, use 15% glacial acetic acid for 30 minutes to adjust the pH to 4.6, and precipitate erythromycin thiocyanate, Continue to stir for 10 minutes, centrifugally filter, and wash the filter cake with hot water at 55°C, and the dosage is 1B of the volume of the mother liquor. Filtrate, and when the wet powder is dri...

Embodiment 2

[0057] 500L of erythromycin fermentation broth, with a titer of 8000μ / ml, was filtered through a 50nm ceramic membrane at a temperature of 10°C, and the resulting filtrate was ultrafiltered through a coiled membrane with a molecular weight cut-off of 50,000. The obtained ultrafiltrate is purified by a LX-98 resin column to obtain a column solution, and the column solution is subjected to nanofiltration through a nanofiltration membrane with a molecular weight cut-off of 200 until the titer of the concentrated solution is 25000u / ml. In the concentrated solution, add sodium thiocyanate with a molar ratio of 1.5 to erythromycin, finish adding in 1.5h, continue to react for 0.5h after adding, adjust pH to 4.7 with 20% glacial acetic acid for 20min, and precipitate erythromycin thiocyanate , continue to stir for 20 minutes, centrifuge and filter, and wash the filter cake with hot water at 55° C., the dosage is 1.5B of the volume of the mother liquor. Filter and dry the wet powder a...

Embodiment 3

[0060] 1000L of erythromycin fermentation broth with a titer of 8000u / ml was filtered through a 50nm ceramic membrane, and the resulting filtrate was ultrafiltered through a coiled membrane with a molecular weight cut-off of 35,000. The obtained ultrafiltrate is purified by one or more LX-98 resin columns to obtain the column solution, which is then subjected to nanofiltration through a nanofiltration membrane with a molecular weight cut-off of 500 until the titer of the concentrated solution is 20000 μ / ml. In the concentrated solution, add sodium thiocyanate with a molar ratio of 1.2 to erythromycin, add it in 2 hours, continue the reaction for 0.5 minutes, use 25% glacial acetic acid aqueous solution to adjust the pH to 4.8 within 30 minutes, and precipitate erythromycin thiocyanate. Continue to stir for 10 minutes, centrifugally filter, and wash the filter cake with hot water at 55°C, and the dosage is 2B of the volume of the mother liquor. Filtrate, and dry the wet powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Potency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com