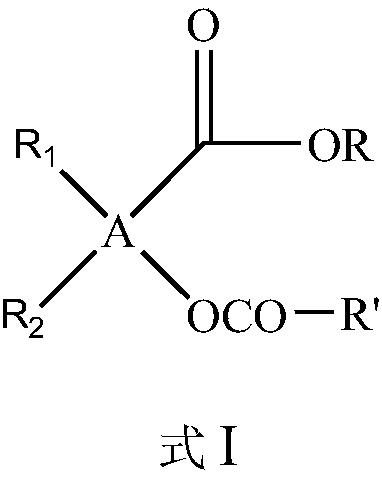

Catalyst component for olefin polymerization, catalyst and application

A technology of olefin polymerization and catalyst, which is applied in the field of olefin polymerization, and can solve problems such as the overall effect of the catalyst is not outstanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

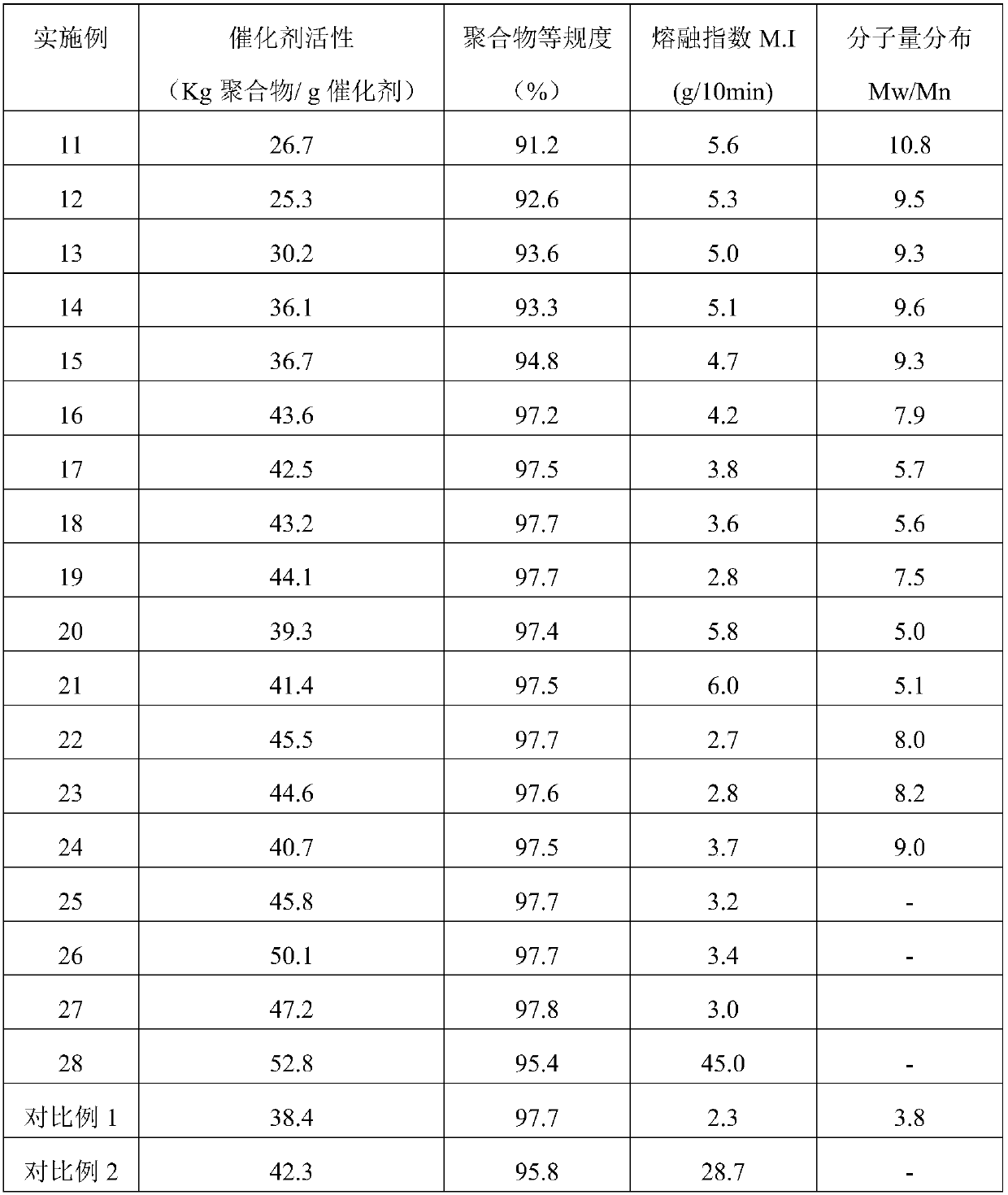

Examples

Embodiment 1

[0072] The synthesis of embodiment 1 compound benzoic acid (ethoxycarbonyl) (phenyl) methyl ester

[0073] In a 250 ml three-necked flask, 1.80 g of ethyl mandelate, 80 ml of toluene and 1.02 g of triethylamine were added after purging with nitrogen, and stirred evenly at room temperature. 1.40 g of benzoyl chloride dissolved in 40 ml of toluene solution was slowly added dropwise at low temperature, stirred at room temperature for 4 hours and then heated to reflux for 12 hours. The reaction solution was cooled to room temperature, and an appropriate amount of water was added to dissolve the precipitate. Extract three times with anhydrous ether. The combined organic phases were dried overnight over anhydrous magnesium sulfate. After concentration under reduced pressure, the mixture was separated by column chromatography with ether / ethanol (1:20) to obtain a light yellow viscous liquid, which was dried in vacuo to obtain 2.04 g of the product (yield 72%).

[0074] The product...

Embodiment 2

[0075] The synthesis of embodiment 2 compound 4-n-butylbenzoic acid (ethoxycarbonyl) (phenyl) methyl ester

[0076] In a 250 ml three-necked flask, 1.80 g of ethyl mandelate, 80 ml of tetrahydrofuran and 1.05 g of triethylamine were added after purging with nitrogen, and stirred evenly at room temperature. 1.96 g of 4-n-butylbenzoyl chloride dissolved in 40 ml of tetrahydrofuran solution was slowly added dropwise at low temperature, stirred at room temperature for 4 hours, then heated and refluxed for 12 hours. The reaction solution was cooled to room temperature, and an appropriate amount of water was added to dissolve the precipitate. Extract three times with anhydrous ether. The combined organic phases were dried overnight over anhydrous magnesium sulfate. After concentration under reduced pressure, the mixture was separated by column chromatography with ether / ethanol (1:20) to obtain a light yellow viscous liquid, which was dried in vacuo to obtain 2.27 g of the product ...

Embodiment 3

[0078] The synthesis of embodiment 3 compound 4-isobutylbenzoic acid (ethoxycarbonyl) (phenyl) methyl ester

[0079] In a 250 ml three-necked flask, 1.80 g of ethyl mandelate, 80 ml of toluene and 1.05 g of triethylamine were added after purging with nitrogen, and stirred evenly at room temperature. 1.96 g of 4-isobutylbenzoyl chloride dissolved in 40 ml of toluene solution was slowly added dropwise at low temperature, stirred at room temperature for 4 hours, then heated and refluxed for 16 hours. The reaction solution was cooled to room temperature, and an appropriate amount of water was added to dissolve the precipitate. Extract three times with anhydrous ether. The combined organic phases were dried overnight over anhydrous magnesium sulfate. After concentration under reduced pressure, the mixture was separated by column chromatography with ether / ethanol (1:20) to obtain a light yellow viscous liquid, which was dried in vacuo to obtain 2.15 g of the product (63% yield). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com