Two-component water-based polyurethane intermediate coating composition with anti-sagging properties and preparation method thereof

A water-based polyurethane, anti-sagging technology, applied in the field of coatings, can solve problems such as sagging and reducing the water resistance of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

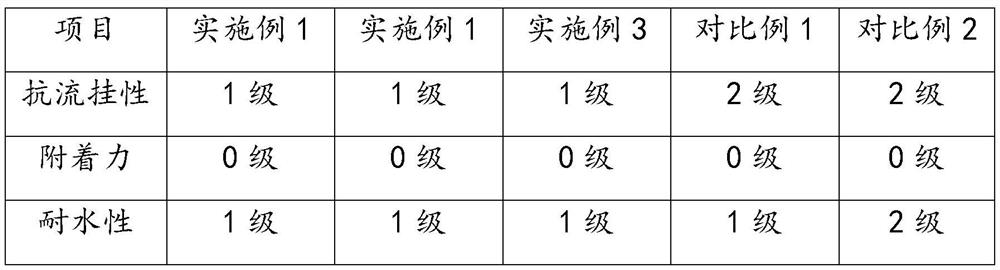

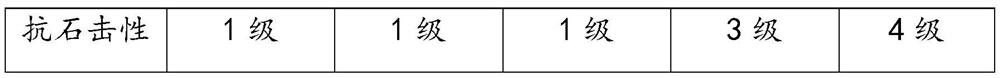

Examples

Embodiment 1

[0059] The two-component water-based polyurethane intermediate coating composition with anti-sagging properties of this embodiment is prepared by mixing component A, component B, and deionized water in a mass ratio of 100:7.94:8, wherein the first component Components were prepared from the following qualities of raw material: 32 grams of hydroxyl functionalized waterborne acrylic resin, 3 grams of butyl glycol acetate, 2 grams of diethylene glycol butyl acetate, 0.4 grams of dispersant Dispers 745W, 0.2g leveling agent BYK-348, 0.1g defoamer Foamex 810, 0.3 grams of pH regulator N,N-dimethylethanolamine, 8 grams of titanium dioxide R 902+, 1 gram of pu carbon black, 33 grams of precipitated barium sulfate, 9 grams of water-based anti-sag polymerization containing polyurea groups and 11 grams of deionized water; component B consists of 80 grams Prepared by mixing XP 2655 and 20 grams of propylene glycol methyl ether acetate.

[0060] The preparation method of the two-comp...

Embodiment 2

[0073] The two-component water-based polyurethane intermediate coating composition with anti-sagging properties of the present embodiment is prepared by mixing component A, component B, and deionized water according to a mass ratio of 100:5.25:5; wherein, the first component Components were prepared from raw materials of the following qualities: 28 g hydroxy-functionalized water-based acrylic resin, 1.5 g butyl glycol acetate, 0.5 g diethylene glycol butyl ether acetate, 1.2 g dispersant EDAPLAN 490, 0.35 g flow Leveling agent BYK-348, 0.3 grams of defoamer BYK-025, 0.1 grams of pH regulator N,N-dimethylethanolamine, 15 grams of titanium dioxide R 902+, 2 grams of pu carbon black, 35 grams of precipitated barium sulfate, 5 Gram talc, 4.5 gram water-based anti-sagging polymers containing polyurea groups and 6.55 gram deionized water; the second component consists of 90 grams 161 and 10 grams of propylene glycol methyl ether acetate mixed in the system.

[0074] The preparatio...

Embodiment 3

[0087] The two-component water-based polyurethane intermediate coating composition with anti-sagging properties of the present embodiment is prepared by mixing component A, component B, and deionized water according to the mass ratio of 100:16.49:12.5; wherein, the first Components were prepared from raw materials of the following qualities: 45 grams of hydroxyl-functionalized waterborne acrylic resin, 5 grams of butyl glycol ether acetate, 3 grams of propylene glycol monomethyl ether acetate, 1 gram of diethylene glycol butyl ether acetate, 0.1 grams Dispersant Dispers 745W, 0.1g dispersant EDAPLAN 490, 0.35g leveling agent BYK-348, 0.2g defoamer Foamex 810, 0.45 grams of pH regulator 2-amino-2-methyl-1-propanol, 6 grams of titanium dioxide R 902+, 0.3 grams of phthalocyanine blue 8631, 12 grams of precipitated barium sulfate, 2 grams of talc, 12.5 grams Water-based anti-sag polymer containing polyurea groups and 12 grams of deionized water; the second component is made fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com