Tin plating solution as well as preparation method and application thereof

A technology of tin plating solution and tin ions, applied in the field of tin plating solution and its preparation, can solve the problems of easy oxidation of stannous ions, decrease in current efficiency, unfavorable industrialization, etc., achieve good appearance and reliability, reduce current density, enhance The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

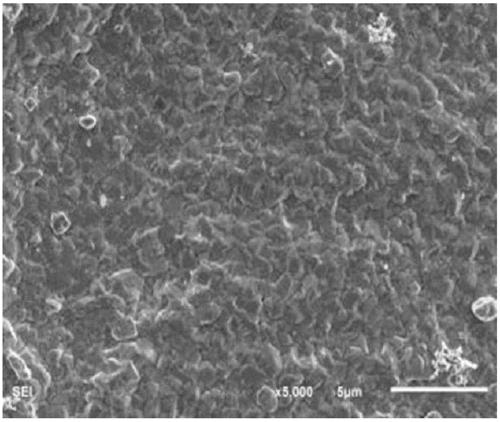

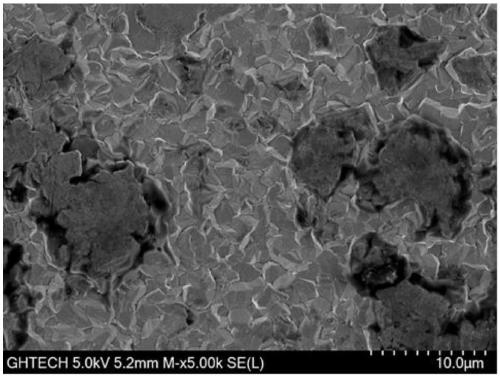

Image

Examples

Embodiment 1

[0047] Components and concentrations of tin plating solution: 0.53mol / L stannous chloride, 1.12mol / L methanesulfonic acid, 0.82mol / L boric acid, 2.62mol / L sodium acetate, 1.26mol / L gluconolactone , Propylene oxide and ethylene oxide copolymer 0.0062mol / L;

[0048] Preparation method: Add gluconolactone, methanesulfonic acid, boric acid and sodium acetate into 3L of water, stir to dissolve, then add stannous chloride, propylene oxide and ethylene oxide copolymer in turn, stir and mix well, Constant volume (10L), the tin plating liquid of making embodiment 1, its pH value is 5.5.

Embodiment 2

[0050] The components and concentrations of the tin plating solution: 0.61mol / L stannous sulfate, 1.34mol / L methanesulfonic acid, 1mol / L boric acid, 2.91mol / L sodium acetate, 1.34mol / L sodium gluconate, Alkyltrimethylammonium chloride 0.0056mol / L;

[0051] Preparation method: Add sodium gluconate, methanesulfonic acid, boric acid and sodium acetate into 3L of water, stir to dissolve, then add stannous sulfate and dodecyltrimethylammonium chloride in turn, stir and mix well, constant volume (10L), the tin-plating liquid of making embodiment 2, its pH value is 5.2.

Embodiment 3

[0053] Components and concentrations of tin plating solution: 0.05mol / L stannous chloride, 0.1mol / L stannous methanesulfonate, 0.39mol / L methanesulfonic acid, 0.54mol / L boric acid, potassium malonate 1.15mol / L, sodium gluconate 0.62mol / L, propylene oxide and ethylene oxide copolymer 0.003mol / L;

[0054] Preparation method: Add sodium gluconate, methanesulfonic acid, boric acid and potassium malonate into 3L of water, stir to dissolve, then add stannous chloride, propylene oxide and ethylene oxide copolymer in turn, stir and mix well , Constant volume (10L), the tin-plating solution of making embodiment 3, its pH value is 4.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com