Titanium and plastic integrated surface treatment method and composite product thereof

A surface treatment and titanium metal technology, applied in the field of innovative surface treatment, can solve problems such as easy degumming and separation, generation of porous bonding layer, and weak bonding of titanium metal substrates, so as to ensure bonding strength, meet integration requirements, and overcome surface Strong activity and easy oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] An integrated surface treatment method for titanium metal and plastic designed in the present invention, which mainly includes the following process flow: degreasing------water washing------acid corrosion------water washing--- --Ash removal------Washing------Activation------Washing------Electrolytic oxidation------Washing------The first soaking Washing --- water washing --- the second immersion --- water washing --- drying, degreasing, acid corrosion, ash removal and activation are pretreatment processes, the first The first rinsing, the second rinsing and drying are post-processing procedures, and the operation process of each process step is described in detail below.

[0046] (1) Pre-processing:

[0047] 1. Degreasing to remove oil stains on the surface of titanium workpieces. Since the surface of titanium metal is easy to form an extremely thin and dense oxide film, it has extremely high stability in the air and in acid, alkali and salt solutions, so it is basical...

Embodiment 2

[0070] See Figure 4 , a composite product produced by an integrated surface treatment method of titanium metal and plastic designed in the present invention, which includes: a titanium alloy test piece 1 and a plastic layer 2 integrally formed on the surface of the test piece.

[0071] The preparation process of composite products:

[0072] (2) Process the industrial titanium alloy plate into a test piece with a length of 50mm, a width of 15mm, and a thickness of 1mm. The processing method can be any one of forging, stamping, wire cutting, and CNC;

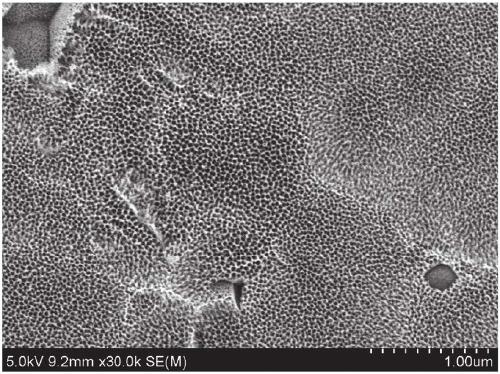

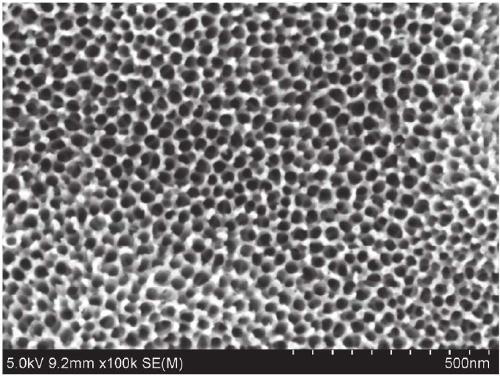

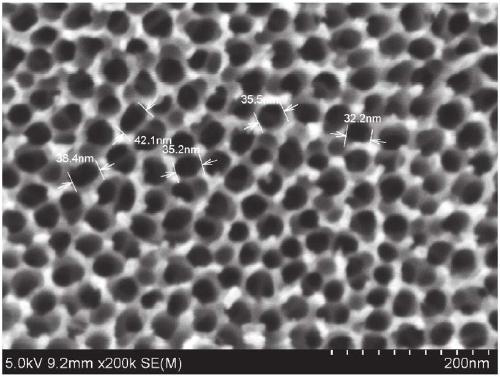

[0073] (1) Preparation of the microporous bonding layer on the surface of the test piece, the test piece is fixed with a titanium wire or a special titanium hanger, and after the pretreatment, electrolytic oxidation and posttreatment procedures included in Example 1 of the present invention, the test A microporous bonding layer is formed on the surface of the sheet;

[0074] (2) Titanium-plastic integrated injection molding, pu...

Embodiment 3

[0080] A composite product manufactured by the integrated surface treatment method of titanium metal and plastic designed in the present invention comprises: a titanium alloy mobile phone middle frame 3 and a plastic part 4 integrally formed on the mobile phone middle frame.

[0081] The preparation process of composite products:

[0082] (2) Forging, stamping or CNC processing of industrial titanium alloy plates, and then grinding, trimming and cleaning to obtain semi-finished blanks for the middle frame of mobile phones;

[0083] (1) Preparation of the microporous bonding layer on the surface of the middle frame of a titanium alloy mobile phone. The middle frame of the mobile phone is fixed with a special titanium hanger. A microporous bonding layer is formed on the surface of the middle frame of the mobile phone;

[0084](2) Titanium-plastic integrated injection molding, put the processed mobile phone middle frame into the customized mold in the injection molding machine, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com