A nano-electrospun membrane with high selectivity for amino acids and its preparation method

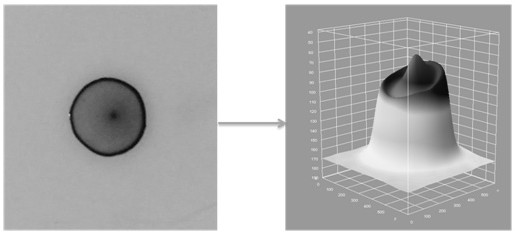

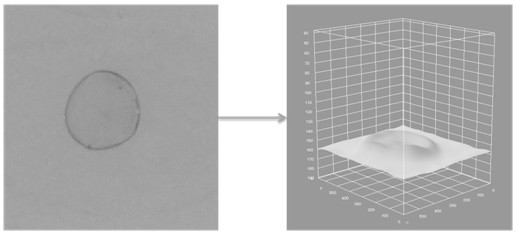

A technology for amino acid and selectivity, applied in electrospinning, rayon manufacturing, textile and paper making, etc., can solve problems affecting amino acid adsorption capacity and specific recognition ability, small specific surface area, large diameter, etc., to achieve good selection Effects of adsorption capacity, large specific surface area, and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

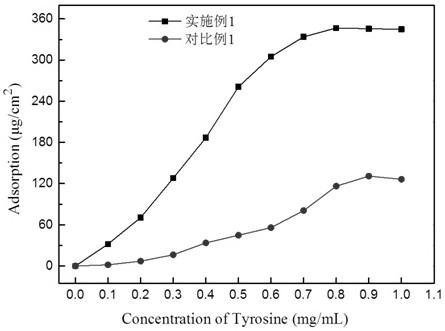

Embodiment 1

[0033] (1) Dissolve 10 mg of p-hydroxyphenylpropionic acid as a simulated template in 15 mL of deionized water, then add 2.0 g of polyvinyl alcohol (PVA1799) powder to fully dissolve, and magnetically stir at room temperature for 20 minutes for defoaming treatment. Heating to 95°C and magnetically stirring for 5 h to prepare the spinning solution.

[0034] (2) The spinning solution obtained in (1) was left to defoam for 24 h until there were no bubbles in the solution, and then the solution was injected into a syringe with a diameter of 1 cm and a range of 20 mL. The electrospun nanomembrane was prepared by spinning on the machine for 2 h, wherein the spinning voltage was 15 kV; the spinning distance was 15 cm; the rotating speed of the spinning drum was 500 rps; %; the temperature is 30°C.

[0035] (3) Remove the electrospun nanomembrane obtained in (2), cut into several pieces of 5.0 cm×2.0 cm electrospun nanomembrane with scissors, and then place the cut membrane in a vacuum...

Embodiment 2

[0044] (1) Dissolve 8.0 mg of p-hydroxyphenylpropionic acid as a simulated template in 12 mL of deionized water, then add 2.0 g of polyvinyl alcohol (PVA1799) powder to fully dissolve, and magnetically stir at room temperature for 20 minutes for defoaming treatment. Heating to 95°C and magnetically stirring for 5 h to prepare the spinning solution.

[0045] (2) The spinning solution obtained in (1) was left to defoam for 24 h until there were no bubbles in the solution, and then the solution was injected into a syringe with a diameter of 1 cm and a range of 20 mL. The electrospun nanomembrane was prepared by spinning on the machine for 2 h, wherein the spinning voltage was 15 kV; the spinning distance was 15 cm; the rotating speed of the spinning drum was 500 rps; %; the temperature is 30°C.

[0046] (3) Remove the electrospun nanomembrane obtained in (2), cut into several pieces of 5.0 cm×2.0 cm electrospun nanomembrane with scissors, and then place the cut membrane in a vac...

Embodiment 3

[0049] (1) Dissolve 10 mg of p-hydroxyphenylpropionic acid as a simulated template in 20 mL of deionized water, then add 1.6 g of polyvinyl alcohol (PVA1799) powder to fully dissolve, and magnetically stir at room temperature for 20 min for defoaming treatment. Heating to 95°C and magnetically stirring for 5 h to prepare the spinning solution.

[0050] (2) The spinning solution obtained in (1) was left to defoam for 24 h until there were no bubbles in the solution, and then the solution was injected into a syringe with a diameter of 1 cm and a range of 20 mL. The electrospun nanomembrane was prepared by spinning on the machine for 2 h, wherein the spinning voltage was 15 kV; the spinning distance was 15 cm; the rotating speed of the spinning drum was 500 rps; %; the temperature is 30°C.

[0051] (3) Remove the electrospun nanomembrane obtained in (2), cut into several pieces of 5.0 cm×2.0 cm electrospun nanomembrane with scissors, and then place the cut membrane in a vacuum d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com