Method for identifying organic sulfide in rubber

An identification method and sulfide technology, applied in the field of analysis, can solve the problems of inability to directly extract and detect, difficult to identify organic small molecules, and long sample processing time, and achieve the effects of protecting environmental health, shortening extraction time, and shortening soaking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

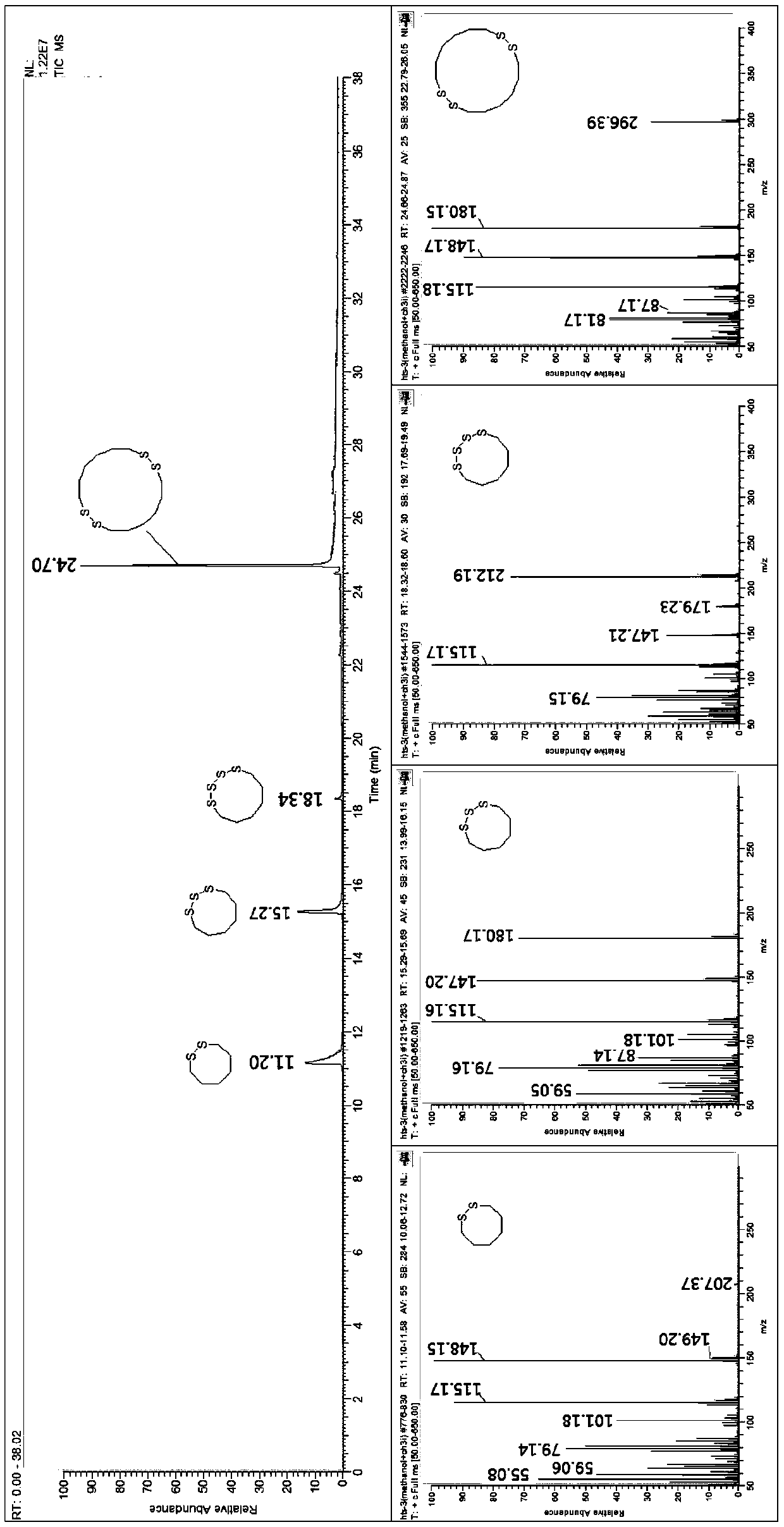

[0051] Example 1: Analysis of HTS in known vulcanized rubber

[0052] Laboratory preparation of vulcanizates:

[0053] The formula of vulcanized rubber is (parts by mass): 40 parts of natural rubber NR, 60 parts of butadiene rubber BR; 75 parts of carbon black N375, 4.0 parts of operating oil, 2.0 parts of stearic acid, 1.5 parts of zinc oxide, 4.0 parts of tackifying resin, anti-aging 2.0 parts of agent 4020, 1.5 parts of anti-aging agent RD, 1.5 parts of sulfur, 1.6 parts of vulcanization accelerator DZ, 1.5 parts of HTS, and 0.2 parts of anti-scorch agent CTP.

[0054] Preparation process: use a 1.6-liter Banbury internal mixer (produced by FARREL company), mix rubber, carbon black and other compounds except sulfur, vulcanization accelerator and anti-scorch agent CTP for 6 minutes and heat up to 160 ° C to obtain the mother Mix the rubber, and cool the masterbatch to below 90°C; then use an open rubber mixer to mix the vulcanization accelerator, sulfur and anti-scorch agen...

Embodiment 2

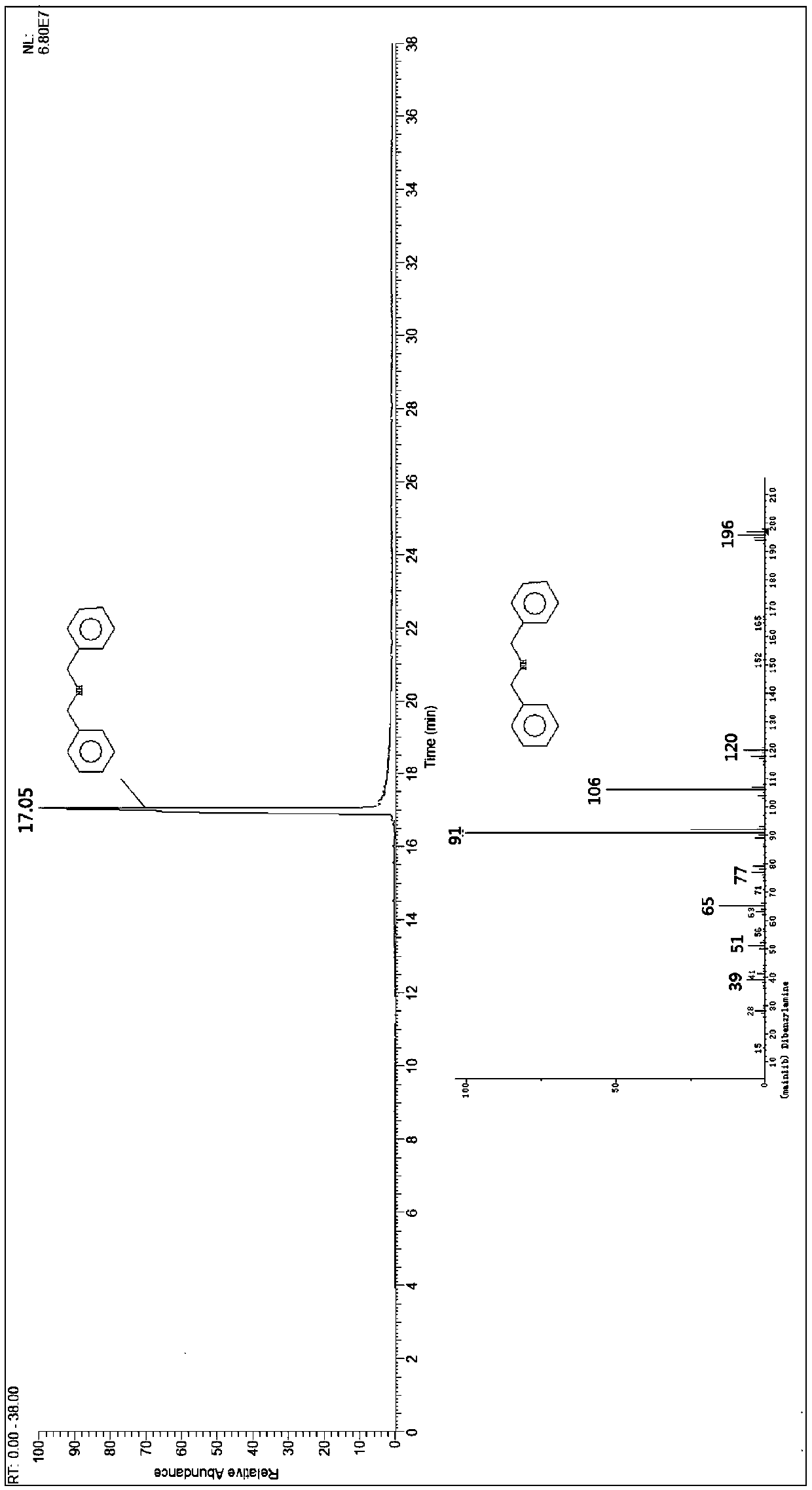

[0075] Embodiment 2: the analysis of the vulcanized rubber containing accelerator TBzTD, not containing organic S-alkyl thiosulfate or its derivatives prepared in laboratory

[0076] Vulcanizate sample preparation:

[0077] The basic formula of vulcanized rubber is (parts by mass): 100 parts of styrene-butadiene rubber ESBR, 30 parts of white carbon black, 40 parts of carbon black N375, 5 parts of silane coupling agent X50S, 4.0 parts of process oil, 2.0 parts of stearic acid, 1.5 parts of zinc oxide 4.0 parts of tackifying resin, 2.0 parts of anti-aging agent 4020, 1.5 parts of anti-aging agent RD, 1.5 parts of sulfur, 1.5 parts of vulcanization accelerator DZ, and 1.0 parts of vulcanization accelerator TBzTD.

[0078] Preparation process: use 1.6 liters of Banbury internal mixer (produced by FARREL company), mix rubber, carbon black and other compounds except sulfur and vulcanization accelerator for 6 minutes and heat up to 160 ° C to obtain masterbatch, and The masterbatch...

Embodiment 3

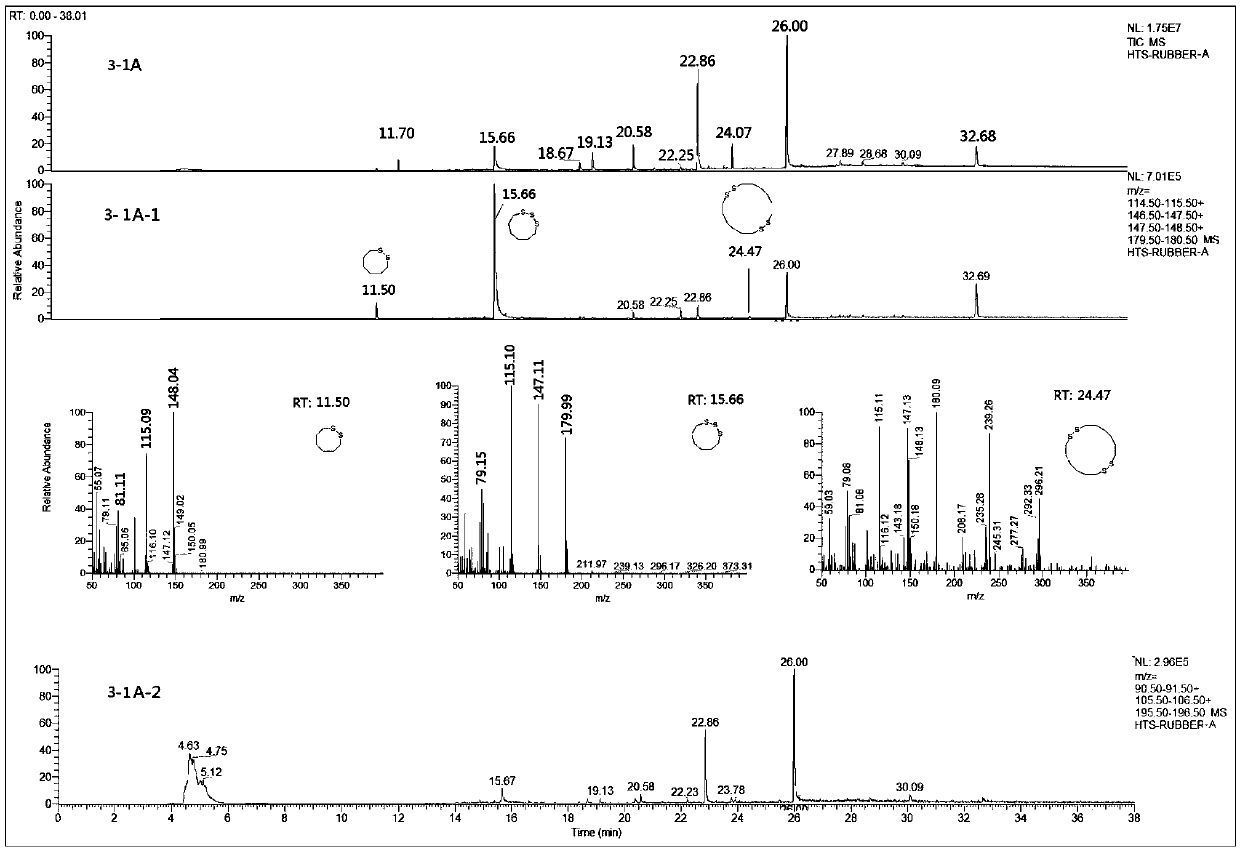

[0091] Embodiment 3: the analysis of certain unknown vulcanized rubber

[0092] Step 1. Sample preparation

[0093] Prepare the sample with a liquid nitrogen cryo-grinder to be less than 0.2mm 3 For small particles, take about 500mg of colloidal particles in the extraction tube, add 10mL of chloroform and 10 drops of potassium iodide, and place the extraction tube in a microwave extractor for 10 minutes; turn on the microwave extractor and perform microwave extraction for 15 minutes at 500W and 40°C; Turn off the extractor, wait for about 30 minutes, take out the extraction tube, and pipette 1 μL of the extract into the GC / MS system for analysis.

[0094] Step 2. GC-MS test

[0095] The chromatographic conditions are: TR-5MS (30m*0.25mm*0.25μm) chromatographic column; the control program of the column temperature is: the initial temperature is 50°C, rises to 310°C at 10°C / min, and maintains for 10min. Carrier gas: He; carrier gas flow rate: 1mL / min. Chromatography mass spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com