Lithium battery current collector and preparation method thereof

A current collector and lithium battery technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve problems such as reducing battery energy density, and achieve the effects of improving adhesion, cycle life and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

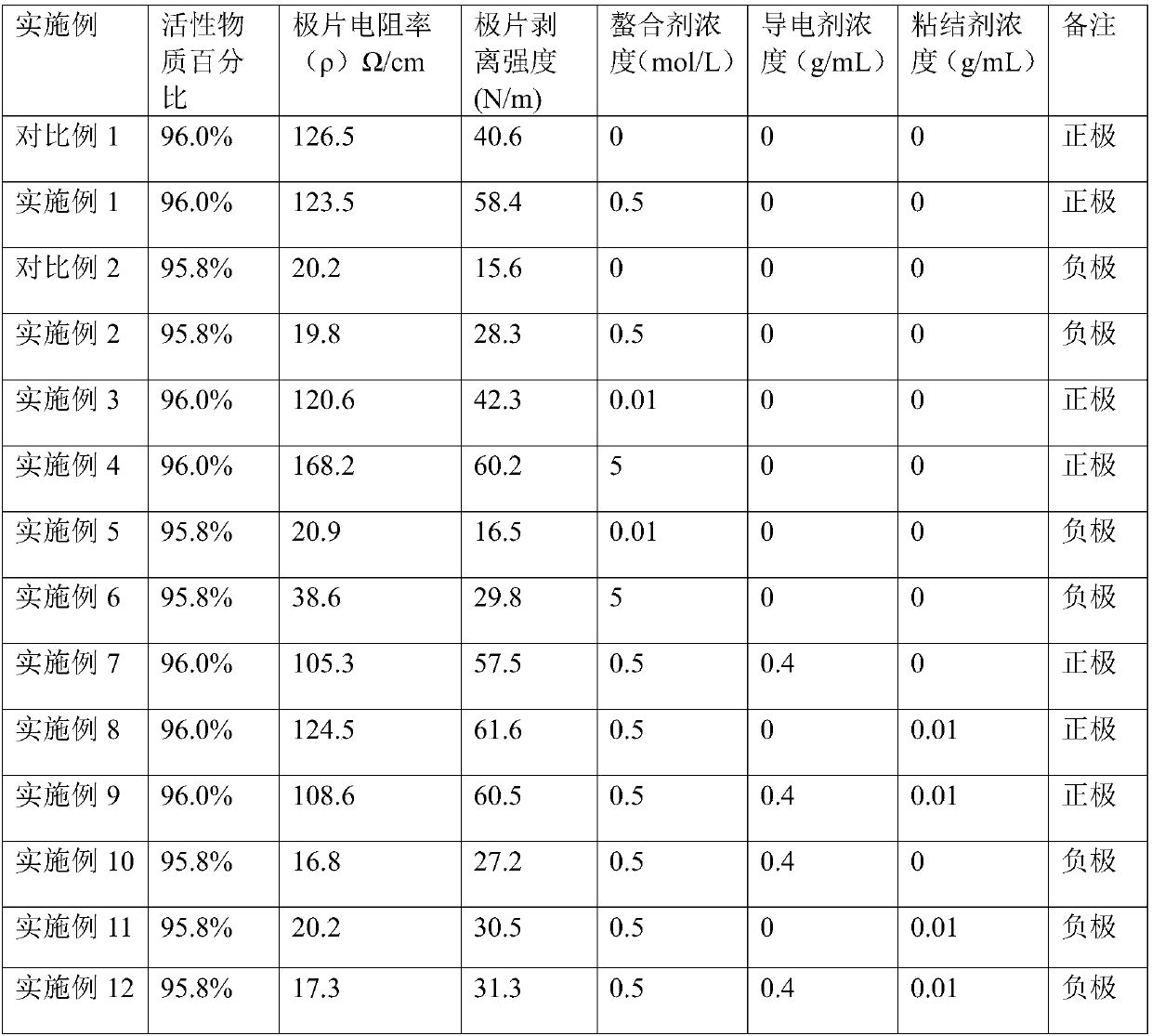

Examples

preparation example Construction

[0021] The preparation method of the new lithium battery current collector is: dispersing the chelating agent in a solvent to prepare a chelating agent dispersion liquid, and then coating the dispersion liquid on at least one surface of the metal foil, and heat-treating to obtain a new lithium battery current collector. fluid;

[0022] The chelating agent is citric acid (CA) and its sodium salt, tartaric acid (TA) and its sodium salt, gluconic acid (GA) and its sodium salt, ethylenediaminetetraacetic acid (EDTA) and its sodium salt, aminotriacetic acid (NTA) and its sodium salt, diethylenetriaminepentaacetic acid and its sodium salt, hydroxyethylethylenediaminetriacetic acid (HEDTA) and its sodium salt, dihydroxyethylglycine (DEG), aminotrimethylene phosphine acid (ATMP), ethylenediaminetetramethylenephosphonic acid (EDTMP), hydroxyethylidenediphosphonic acid (HEDP), diethylenetriaminepentamethylenephosphonic acid (DTPMP), 1,2-dimethyl-3- One or more of hydroxy-4-pyridone (DH...

Embodiment 1

[0039] Disperse 1,2-dimethyl-3-hydroxy-4-pyridone chelating agent in N-methylpyrrolidone solvent to prepare a 0.5mol / L chelating agent dispersion, which is applied to aluminum foil by spraying On the two surfaces of the chelating agent layer, the single-sided surface density of the chelating agent layer is 0.5 mg / cm after heat treatment at 90 ° C for 30 min 2 new collectors. The positive electrode slurry is coated on the new current collector, and the desired positive electrode sheet is obtained through heat treatment and rolling treatment.

Embodiment 2

[0041] Disperse the ethylenediaminetetraacetic acid chelating agent in a water solvent to prepare a 0.5mol / L chelating agent dispersion, apply it to the two surfaces of the copper foil by spraying, and heat-treat at 65°C for 30 minutes to obtain the chelating agent The density of one side of the mixture layer is 0.5mg / cm 2 new collectors. The negative electrode slurry is coated on the new current collector, and the desired negative electrode sheet is obtained through heat treatment and rolling treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com