Decontaminant-doped dry hydrogel particles, macromolecule concentration and specific activity improvement

A technology of macromolecules and detergents, used in solid adsorbent liquid separation, hydrolase, filtration separation, etc., can solve the problems of low local concentration, polarization or loss of active function, clogging and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

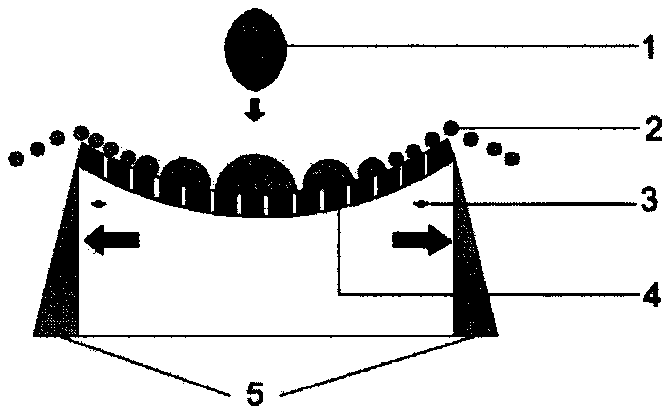

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: preferred conditions

[0020] The type of hydrogel particles: the type of hydrogel particles is selected according to the ease of preparation, preparation cost, and the need for interaction with target macromolecules. Two types of hydrogel particles, polyacrylamide and polydextran, are preferred because of their relative ease and economy of preparation and inertness that do not interact with macromolecules; polyacrylic acid or polyacrylic acid hydrogel particles are preferred because In addition to the ease and economy of its preparation, it also has a huge water absorption per unit gel mass, although the impact of the negative charge it carries on the interaction with the target macromolecule on the concentration process and recovery rate needs to be carefully considered.

[0021] The type and concentration of doped detergent: according to the characteristics of the interaction between target macromolecules and hydrogel particles, select the doped deterge...

Embodiment 2

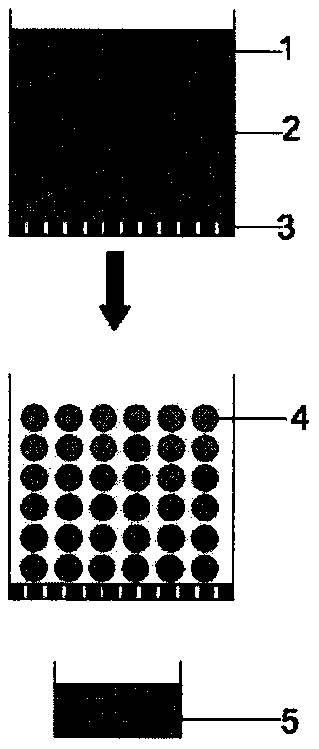

[0025] Example 2: Preparation of detergent-doped dry polyacrylamide hydrogel particles by single-phase polymerization

[0026] Components: 29 grams of acrylamide, 1 gram of N,N-methylenebisacrylamide, 100 milliliters of deionized water, 0.2 grams of ammonium persulfate, and 40 microliters of tetramethylethylenediamine.

[0027] Steps: Dissolve and mix the above-mentioned acrylamide, N,N-methylenebisacrylamide and ammonium persulfate solids in deionized water in a beaker, add tetramethylethylenediamine to start the polymerization reaction, and immediately pour into the bottom area In a larger container with an inert inner surface, let it stand for about 1 hour to complete the polymerization; chop the polymerized gel and dry it at 90°C; crush the dried block polymer in a pulverizer, and screen out 60 ~150 target particles, poured into deionized water to fully swell; wash twice with 250 ml deionized water, and then use 250 ml Tween-20 deionized with a preferred concentration of 0...

Embodiment 3

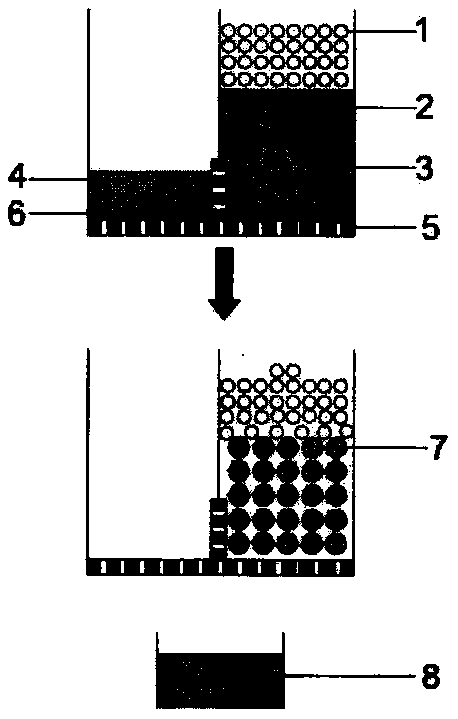

[0028] Example 3: Preparation of detergent-doped dry polyacrylamide particles by reverse-phase suspension polymerization

[0029] Water phase configuration: Mix 29 grams of acrylamide, 1 gram of N,N-methylenebisacrylamide, 100 milliliters of deionized water and 0.2 grams of ammonium persulfate. Oil phase configuration: Mix 200ml cyclohexane and 3ml Span-80.

[0030] Steps: configure the oil phase in a three-necked flask equipped with mechanical stirring and a spherical condenser, raise the temperature to 57°C, and stir at a speed of 240 rpm; configure the water phase in the beaker, add it to the flask and mix with the oil phase, During the stirring operation, the water phase is dispersed into the oil phase, and the temperature is kept at 57°C for 30 minutes; the temperature is raised to 67°C, and a large amount of reflux occurs after the system releases heat, and the heat is kept for 30 minutes after the heat release; After the reaction, remove cyclohexane by vacuum filtratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com